Washing machine with self-cleaning filter and control method thereof

A self-cleaning filter and washing machine technology, which is applied to the control device of the washing machine, other washing machines, household appliances, etc., can solve the problems of difficult handling of lint, labor-intensive manual cleaning, and large space occupied by the filter device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

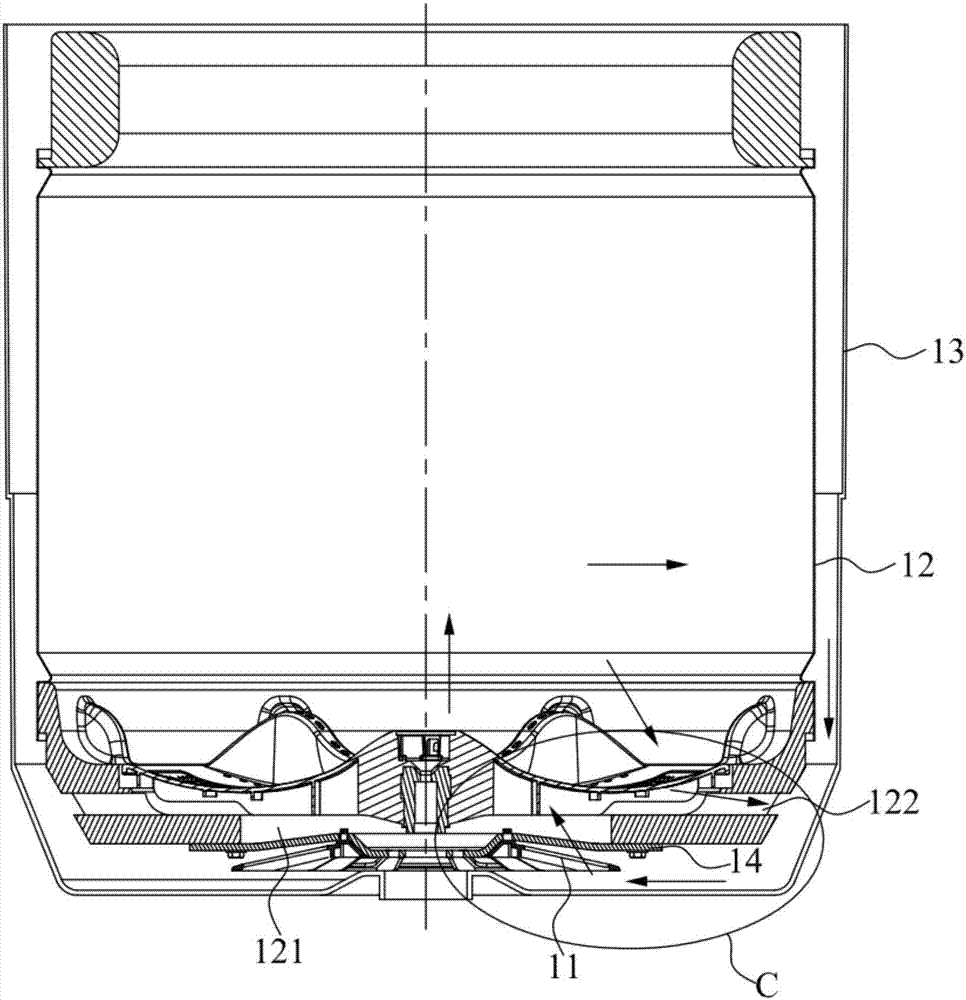

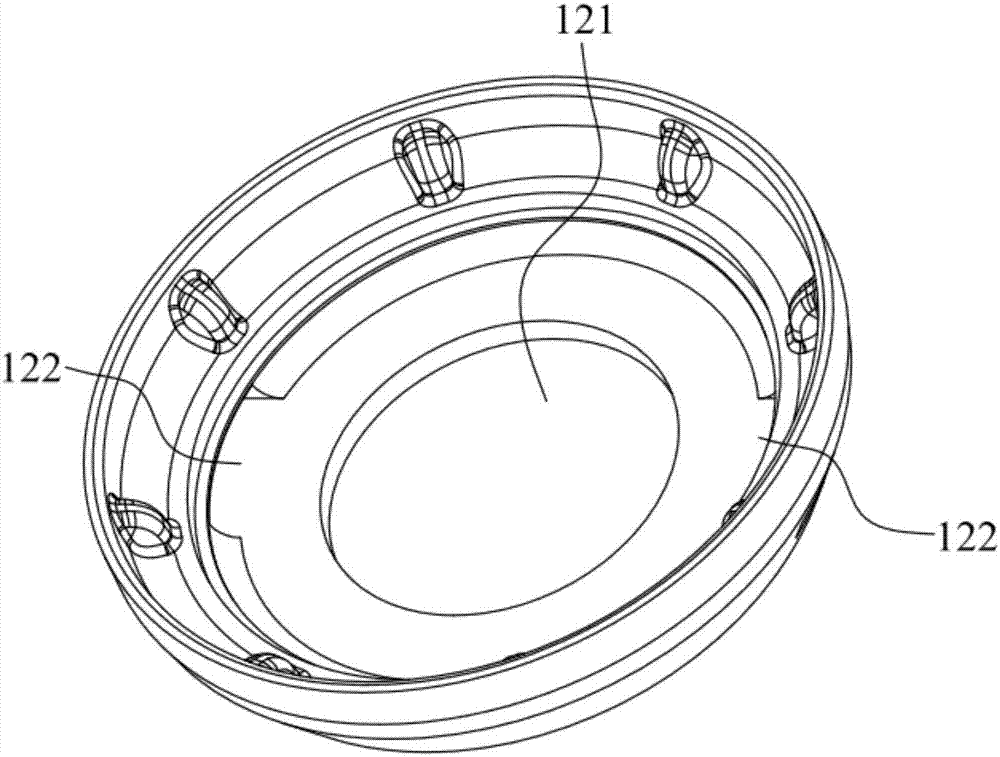

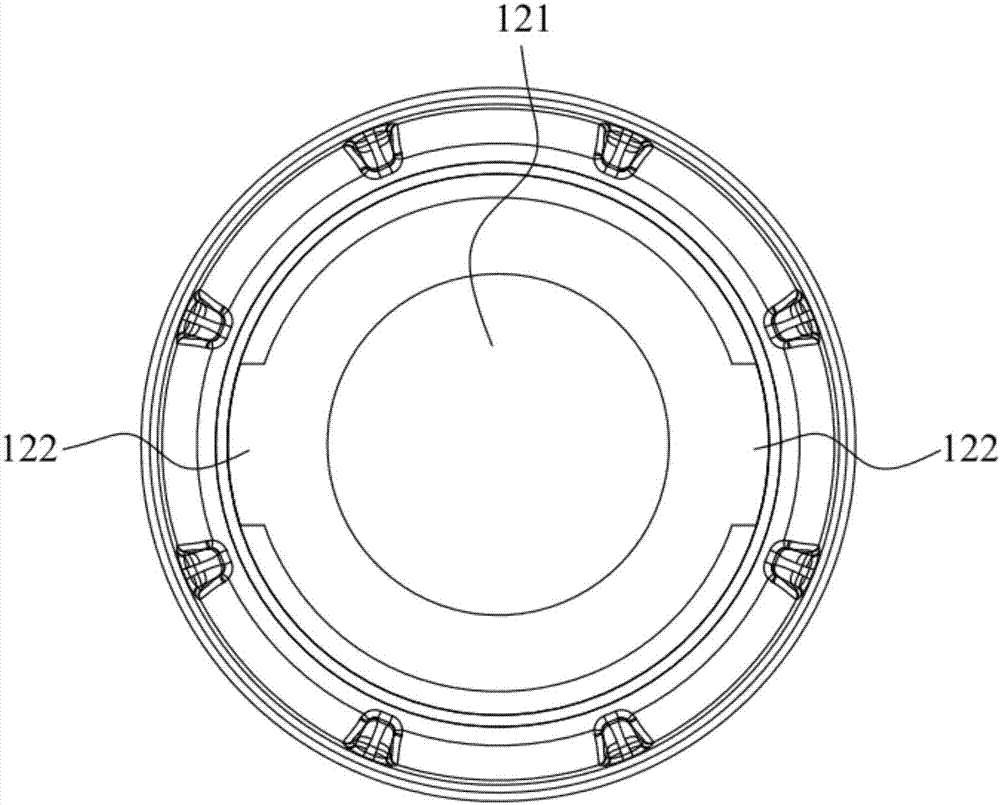

[0039] see figure 1 , a washing machine with a self-cleaning filter, the filter 11 is fixed on the bottom of the inner tub 12 of the washing machine, the outer diameter of the filter 11 is larger than the diameter of the drainage center hole 121 at the bottom of the inner tub 12, and the bottom of the inner tub 12 is provided on the side for The opening 122 through which the washing water passes; the filter 11 uses the washing water to flow through the filter 11 from the bottom of the filter 11 and enters the inner barrel 12 for circulation to realize its filtering function, and the washing water flows through the filter 11 through the drainage center hole 121 to drain to realize its self-discharging. Cleansing effect.

[0040] The filter 11 is fixed on the bottom of the inner tub 12 of the washing machine to avoid occupying the volume of the inner tub 12; the outer diameter of the filter 11 is greater than the diameter of the drainage center hole 121 at the bottom of the inne...

Embodiment 2

[0046] Figure 6 to Figure 8 Embodiment 2 is shown, in which components identical or corresponding to those in Embodiment 1 use the same reference numerals as in Embodiment 1. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that the filter 11 is a stainless steel plate with a plurality of water holes 114 evenly distributed on the stainless steel plate. During the circulation process, the washing water passes through the filter 11, the water flows through the water hole 114, and the wire scraps adhere to the bottom surface of the stainless steel plate. When the washing water washes the stainless steel plate, the surface of the stainless steel plate is smooth and easy to rinse. In this embodiment, the diameter of the water hole 114 is between 4 mm and 6 mm.

[0047] see Figure 6 and Figure 8 , the edge of the stainless steel plate is provided with a curling 113, and the curling 113 is formed by bending the edge of...

Embodiment 3

[0050] Figure 9 to Figure 11 The third embodiment is shown, wherein the parts identical or corresponding to those of the second embodiment adopt the same reference numerals as those of the second embodiment. For simplicity, only the differences between Embodiment 3 and Embodiment 2 are described. The difference is that the filter 11 is a stainless steel plate, the edge of the stainless steel plate is provided with a reinforcing rib 116, the cross section of the reinforcing rib 116 is U-shaped, the reinforcing rib 116 covers the edge of the stainless steel plate, and the reinforcing rib 116 is formed by injection molding. The setting of the reinforcing rib 116 makes the edge thicker, increases the strength and service life of the filter 11, and is not easy to bend during installation. The setting of the reinforcing rib 116 also makes the original sharp edge of the stainless steel plate not exposed, so it will not cause harm to the handling and installation personnel.

[0051...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com