Assembled steel structure prefabricated external wall panel prefabrication and construction method

A technology of prefabricated wall panels and construction methods, applied in manufacturing tools, building structures, ceramic molding machines, etc., can solve problems such as hidden dangers of water leakage, large shrinkage characteristics of materials, easy cracks in materials and steel beams, etc., and achieve simple construction. , Low maintenance cost, and the effect of eliminating the hidden danger of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below with reference to accompanying drawing and embodiment:

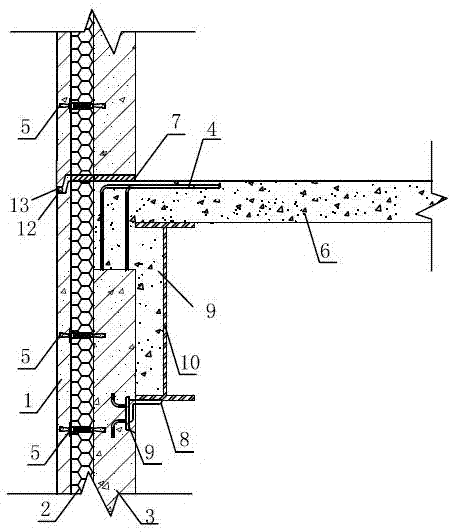

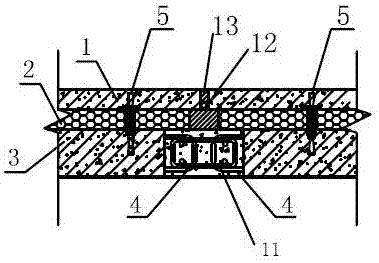

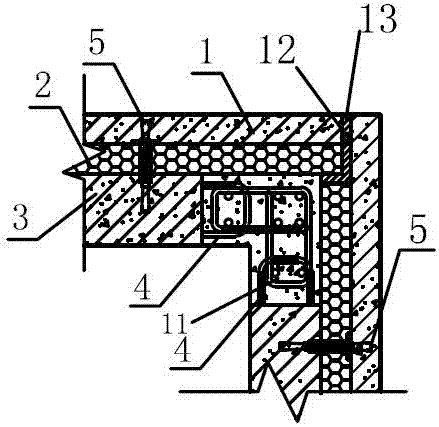

[0030] attached Figure 1-3 It can be seen that a prefabrication and construction method of prefabricated steel structure prefabricated exterior wall panels includes the following steps:

[0031] Prefabricate the back-bonded insulation board 2 in the concrete prefabricated wallboard;

[0032] The outer side of the insulation board 2 is provided with a concrete outer leaf 1 for exterior decoration and protection of the insulation board;

[0033] The inner side of the insulation board 2 is provided with a concrete inner leaf 3 for bearing external force; the inner leaf 3 is the load-bearing layer of the concrete prefabricated wall panel;

[0034] Concrete inner leaves 3 left and right and the top surface protrude from the connecting steel bar 4;

[0035] Wash the rough surface around the concrete inner leaf 3;

[0036] The concrete inside and outside the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com