Geothermal well inside heat exchange pipe installing process

The technology of a heat exchange tube and an installation process is applied in the field of the installation process of the heat exchange tube in a geothermal well, which can solve problems such as difficulty in using geothermal energy, and achieve the effect of solving the difficulty in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

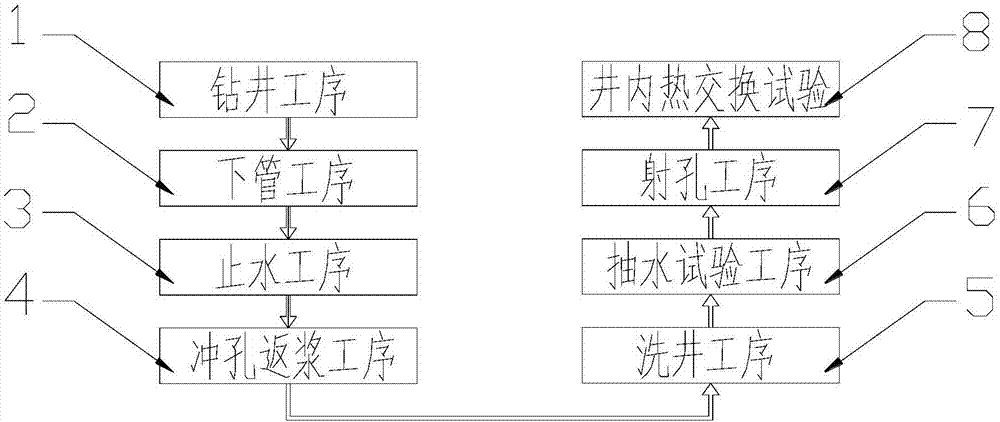

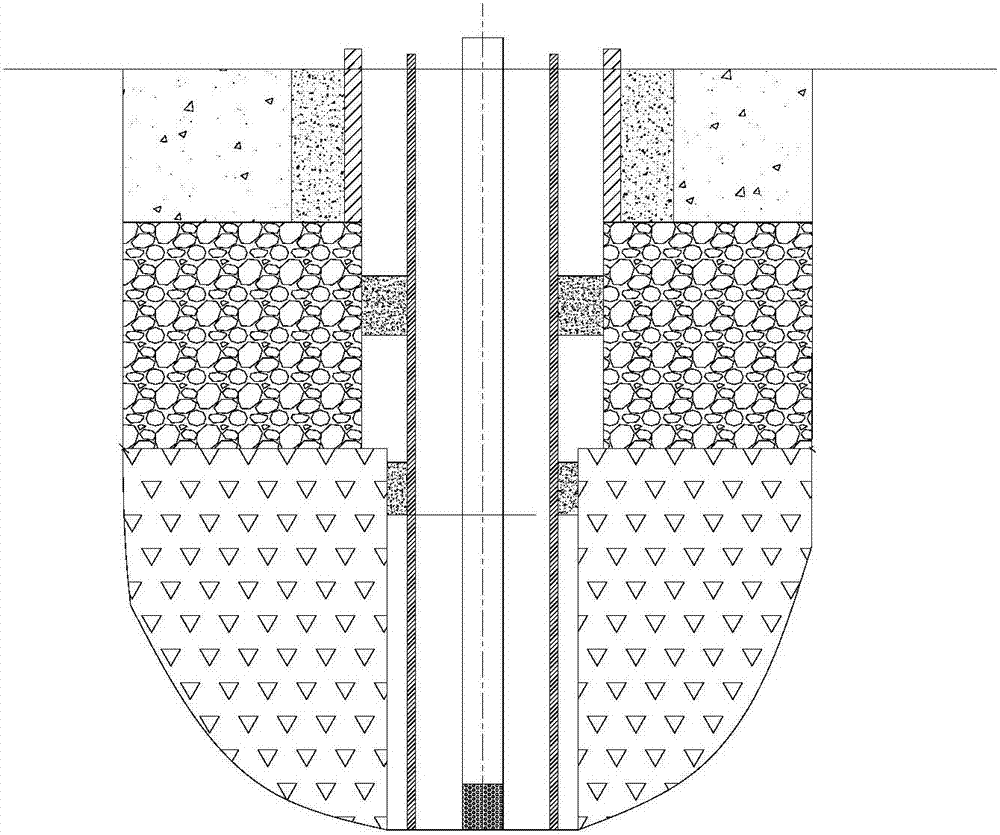

[0029] Such as Figure 1-2 As shown, the present invention provides a heat exchange tube installation process in a geothermal well, including drilling process, pipe lowering process, water stop process, punching and slurry return process, well cleaning process, pumping test process, perforation process and heat exchange experiment in the well The drilling process includes the first spud and the second spud. The first spud is to use a roller cone bit with a diameter of 445 mm to drill to 201.30 meters to form a well section of the pump chamber, and then run a pump with a diameter of 340 mm. From the chamber pipe to the bottom of the pump chamber well section, keep the pump chamber pipe 0.38 meters above the ground. After the pump chamber pipe is lowered, use the high-pressure pumping method to press in cement slurry with a specific gravity of 1.85 from the bottom of the well to the wellhead. The cement is solidified for 24 hours and the second spud is performed. The second spud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com