Method for measuring structural deformation of ballastless rail in real time based on piezoelectric ceramic technology

A technology of piezoelectric ceramics and ballastless track, which is applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, and the use of stable tension/pressure test material strength, etc., which can solve the problem of aggravated maintenance costs and difficulties in meeting expectations Problems such as detection effect, large manpower and material resources are consumed, and the effect of improving detection accuracy and timeliness, reducing manual cycle detection, and ensuring safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0029] The present invention proposes a method for real-time measurement of structural deformation of ballastless track based on piezoelectric ceramic technology, comprising the following steps:

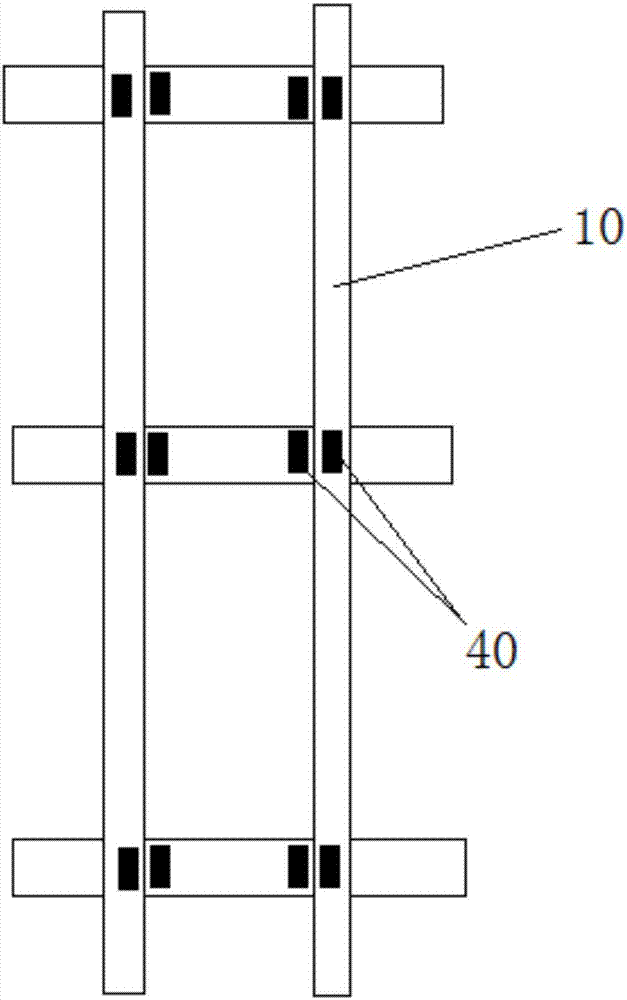

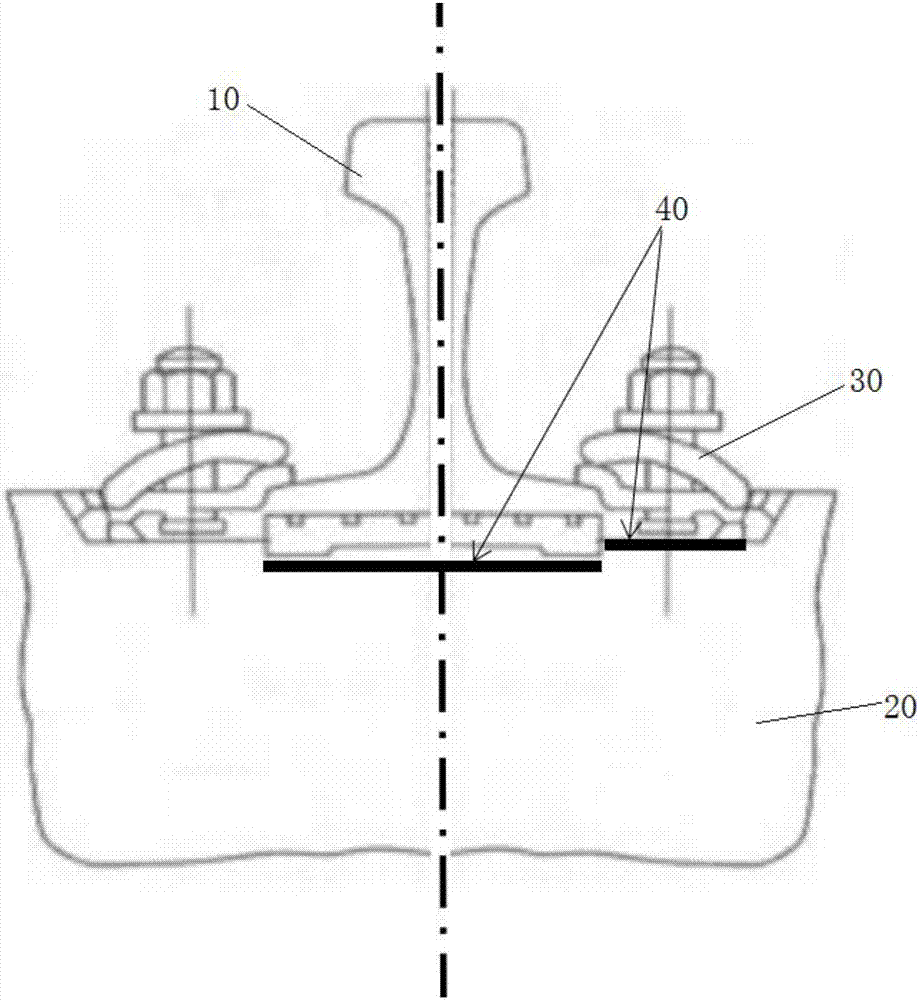

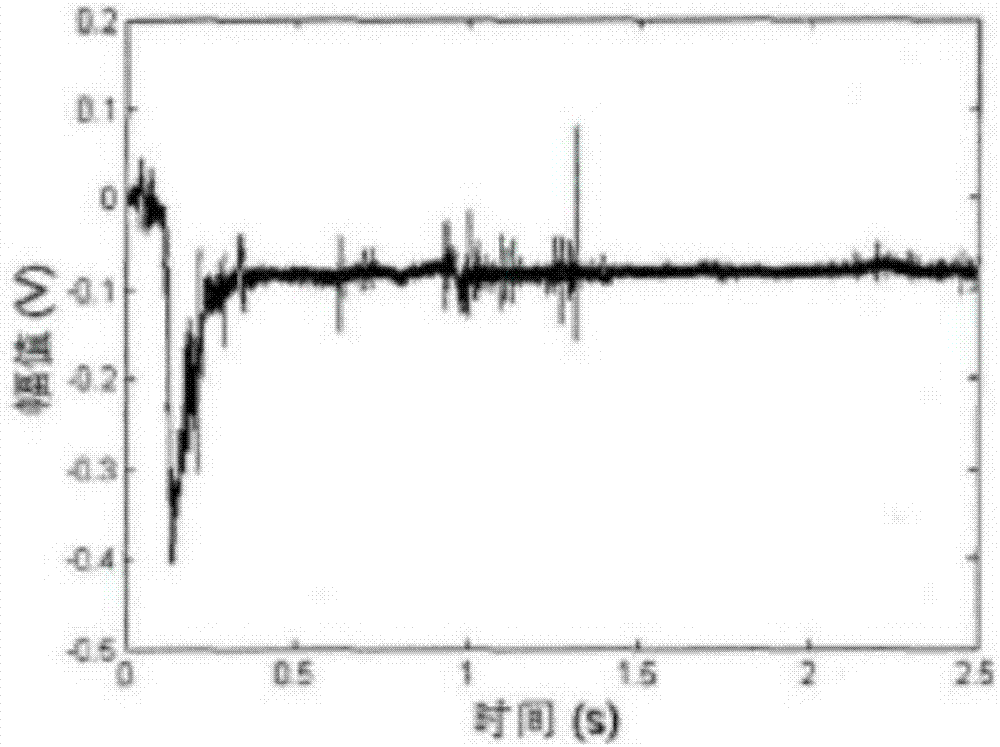

[0030] Step 1, load experiment test, install the piezoelectric ceramic sensor 40 on the ballastless track circuit simulated in the laboratory, apply loads to the rail 10 step by step until the rail 10 is deformed, cracked and destroyed, observe and record the applied load values under different deformation states size F, and at the same time measure the voltage amplitude V corresponding to the output of the piezoelectric ceramic sensor 40 .

[0031] When damage and defects occur in equipment and structures, such as cracks, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com