Method of forming semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve problems such as pattern performance needs to be improved, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] As mentioned in the background, the performance of the pattern in the semiconductor device formed by the self-aligned quadruple patterning technology in the prior art needs to be improved.

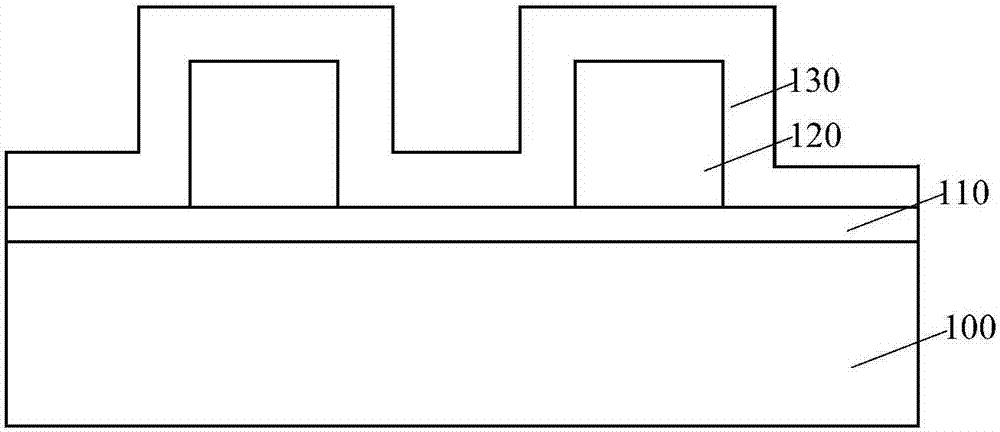

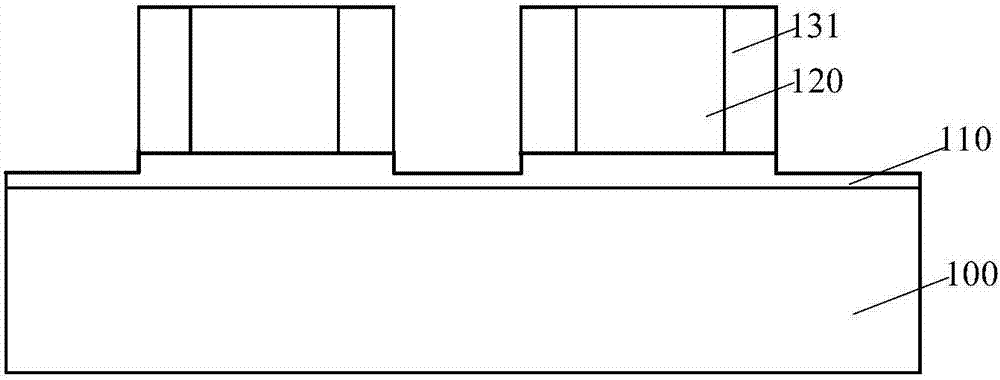

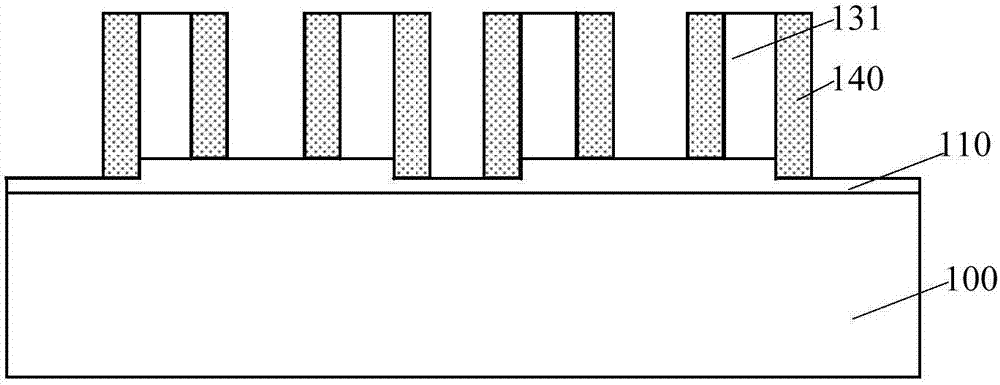

[0035] Figure 1 to Figure 5 It is a structural schematic diagram of the formation process of a semiconductor device.

[0036] refer to figure 1, provide the material layer 100 to be etched, the surface of the material layer 100 to be etched has an etching barrier layer 110; a sacrificial layer 120 with a pattern is formed on the surface of the etching barrier layer 110; The first sidewall material layer 130 is formed with the sidewall surface and the surface of the etch stop layer 110 .

[0037] The material of the etch stop layer 110 is silicon nitride.

[0038] refer to figure 2 , using an anisotropic dry etching process to etch the first sidewall material layer 130 to form the first sidewall 131 .

[0039] refer to image 3 , remove the sacrificial layer 120 (refer to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com