Patents

Literature

44results about How to "Reduce line width roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

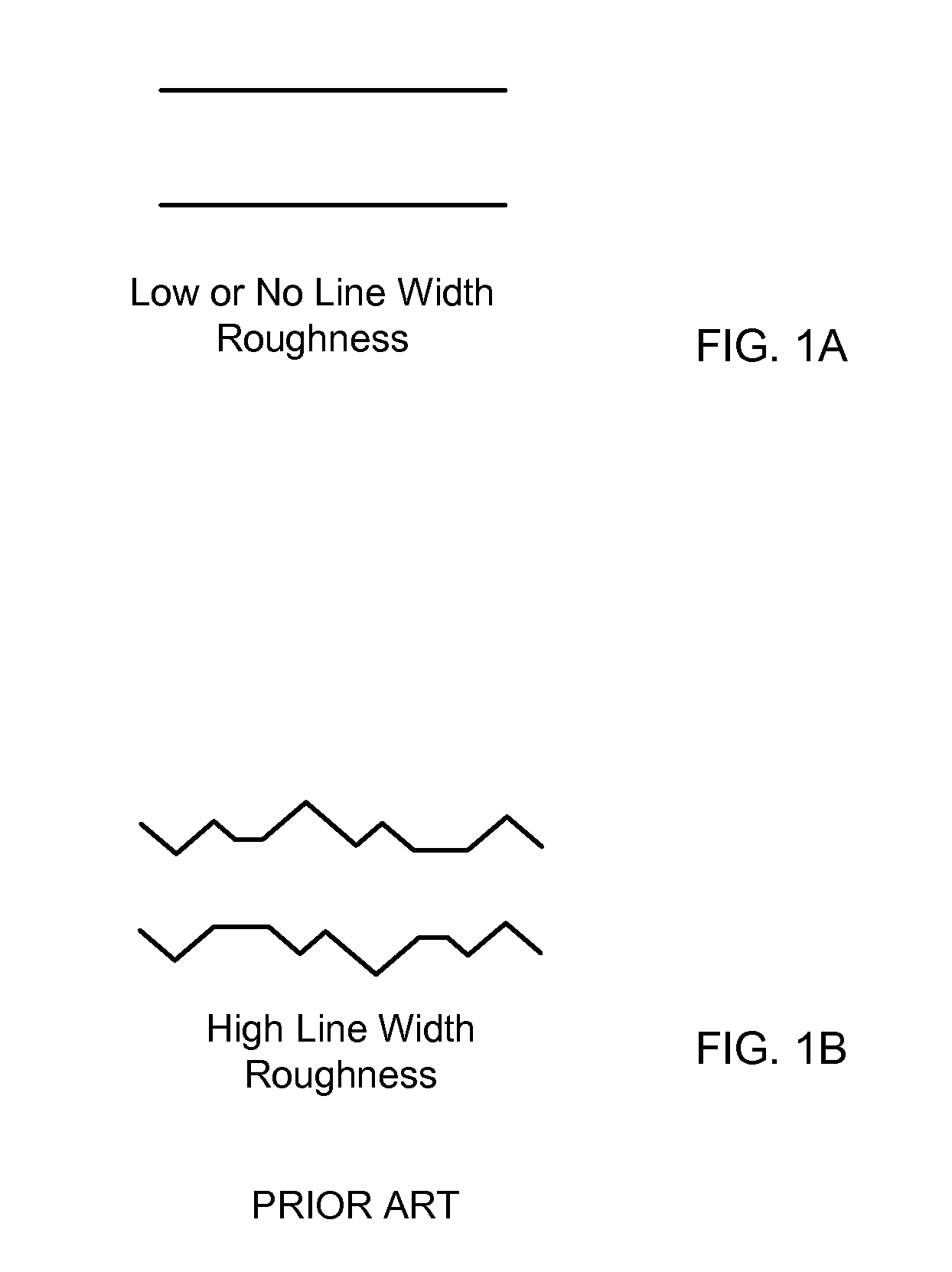

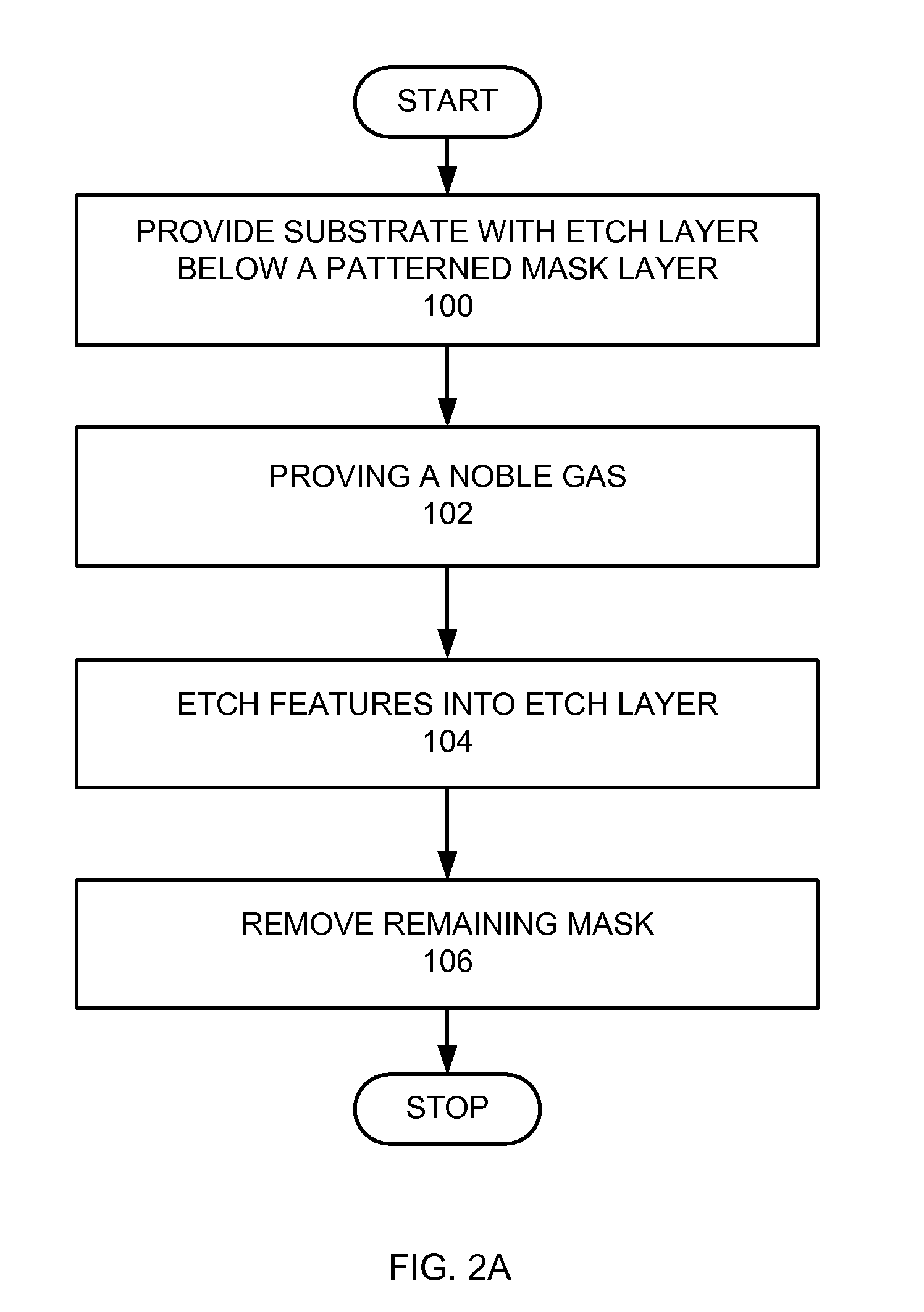

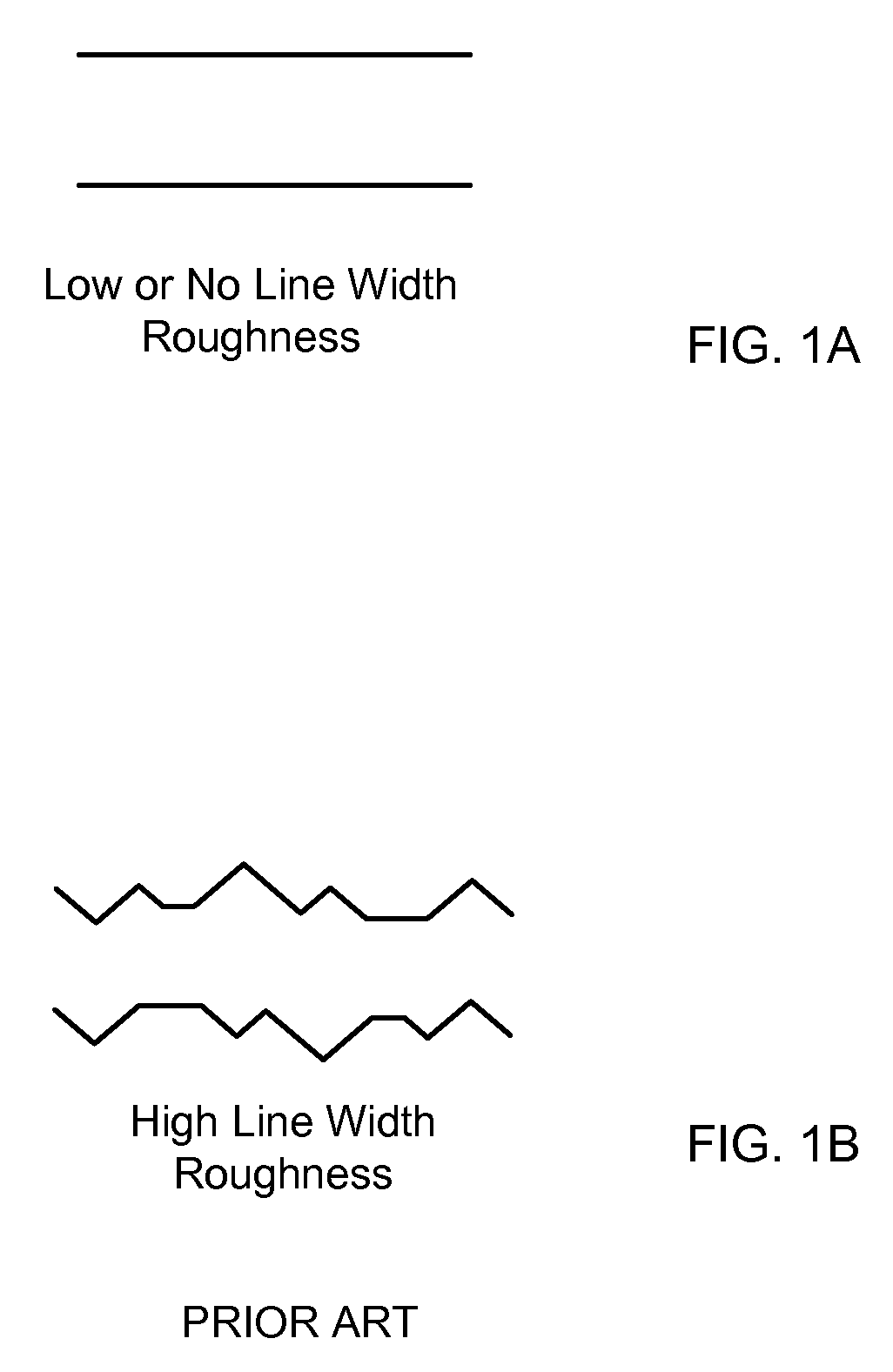

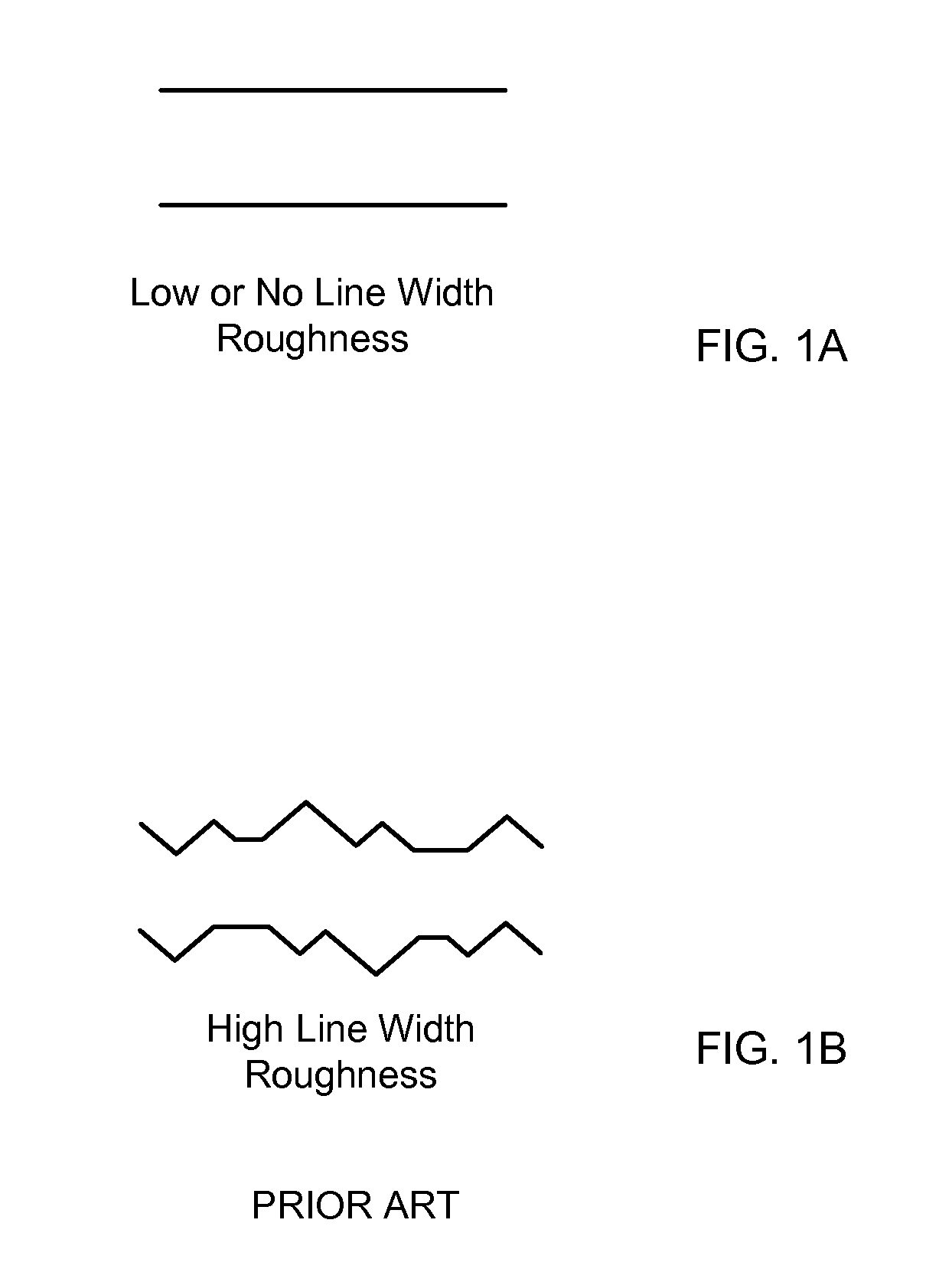

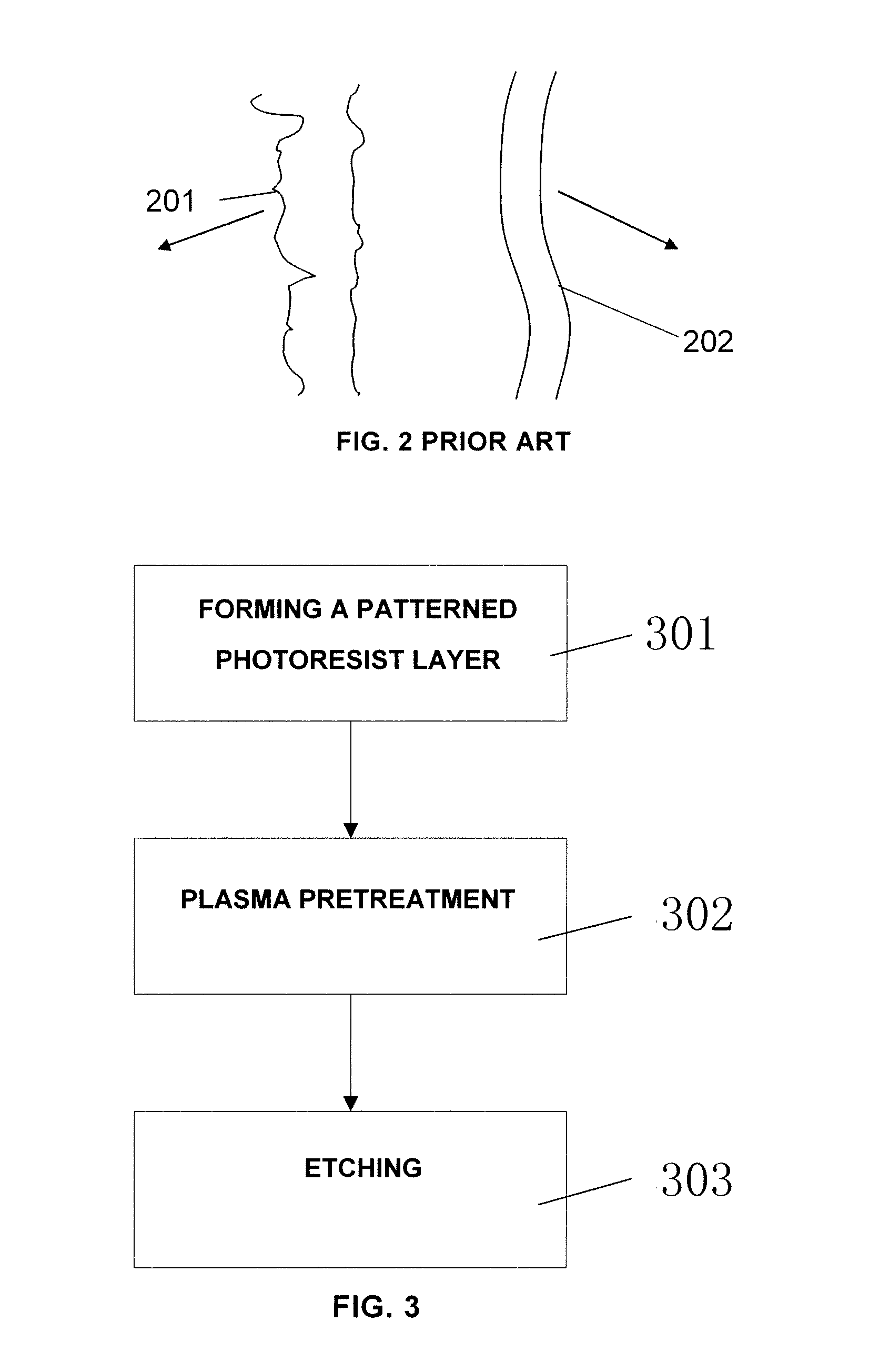

Method for reducing line width roughness with plasma pre-etch treatment on photoresist

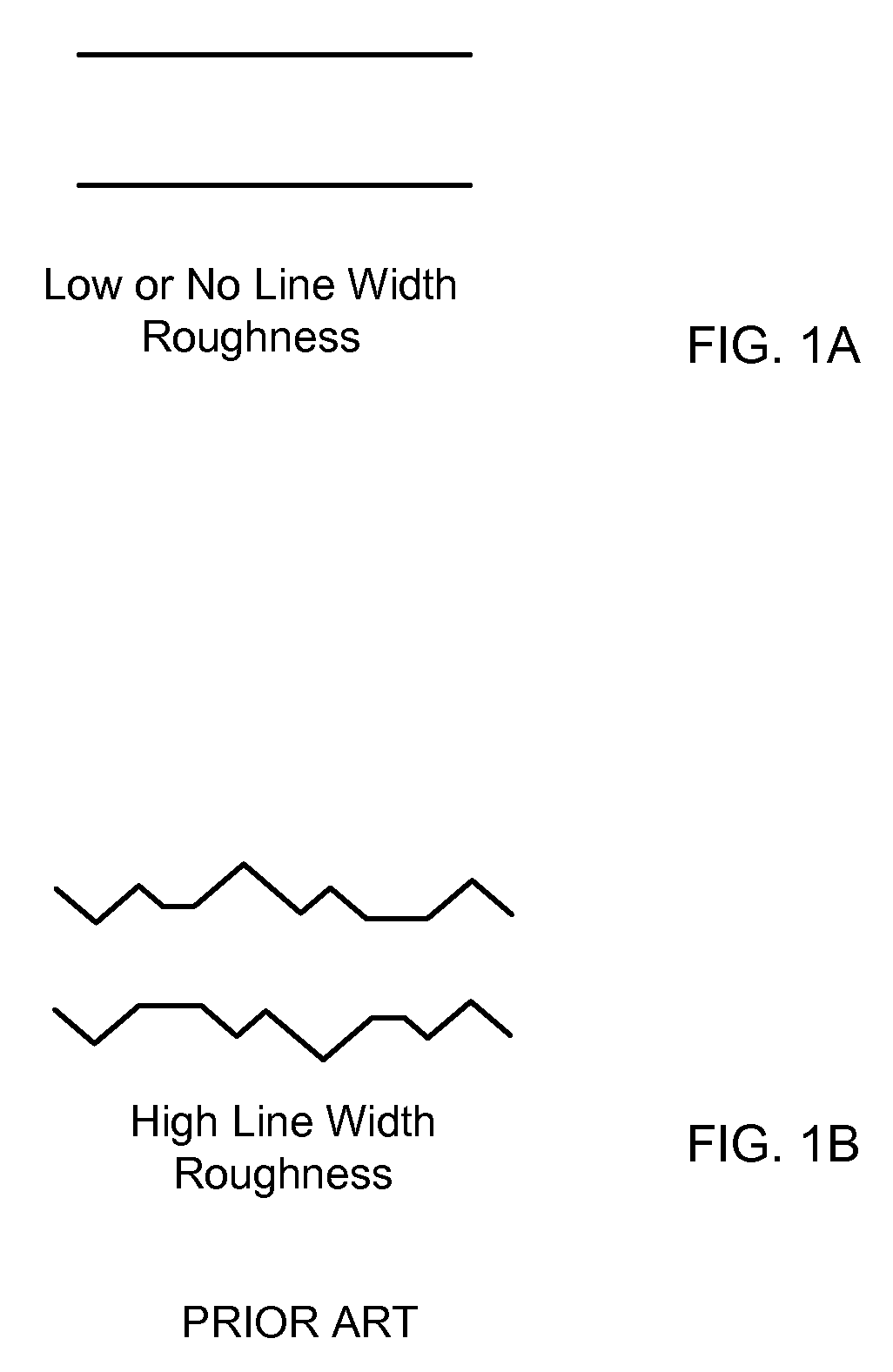

InactiveUS20110117749A1Reduce line width roughnessElectric discharge tubesDecorative surface effectsEtchingLine width

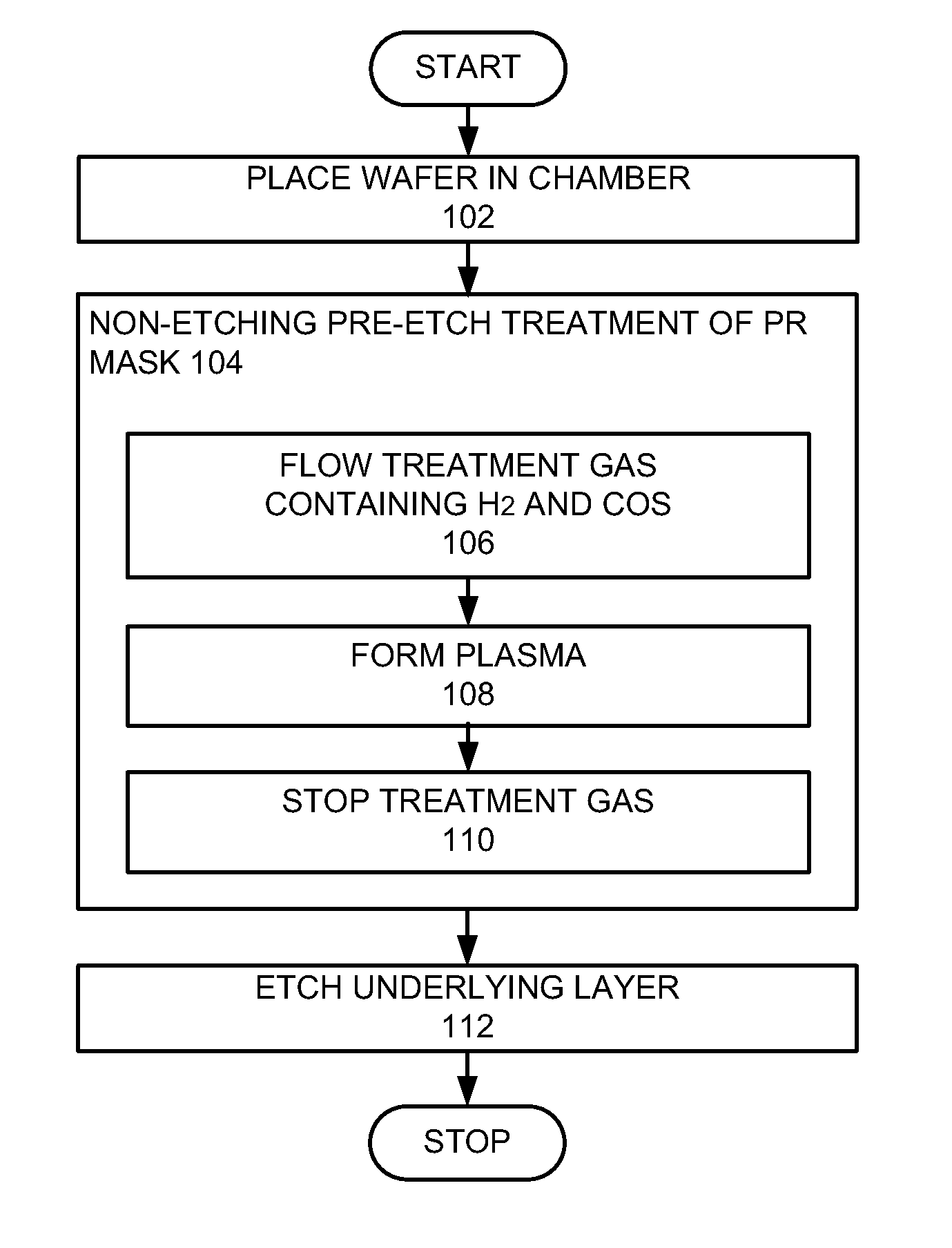

A method for reducing line width roughness (LWR) of a feature in an etch layer below a patterned photoresist mask having mask features is provided. The method includes (a) non-etching plasma pre-etch treatment of the photoresist mask, and (b) etching of a feature in the etch layer through the pre-treated photoresist mask using an etching gas. The non-etching plasma pre-etch treatment includes (a1) providing a treatment gas containing H2 and COS, (a2) forming a plasma from the treatment gas, and (a3) stopping the treatment gas.

Owner:LAM RES CORP

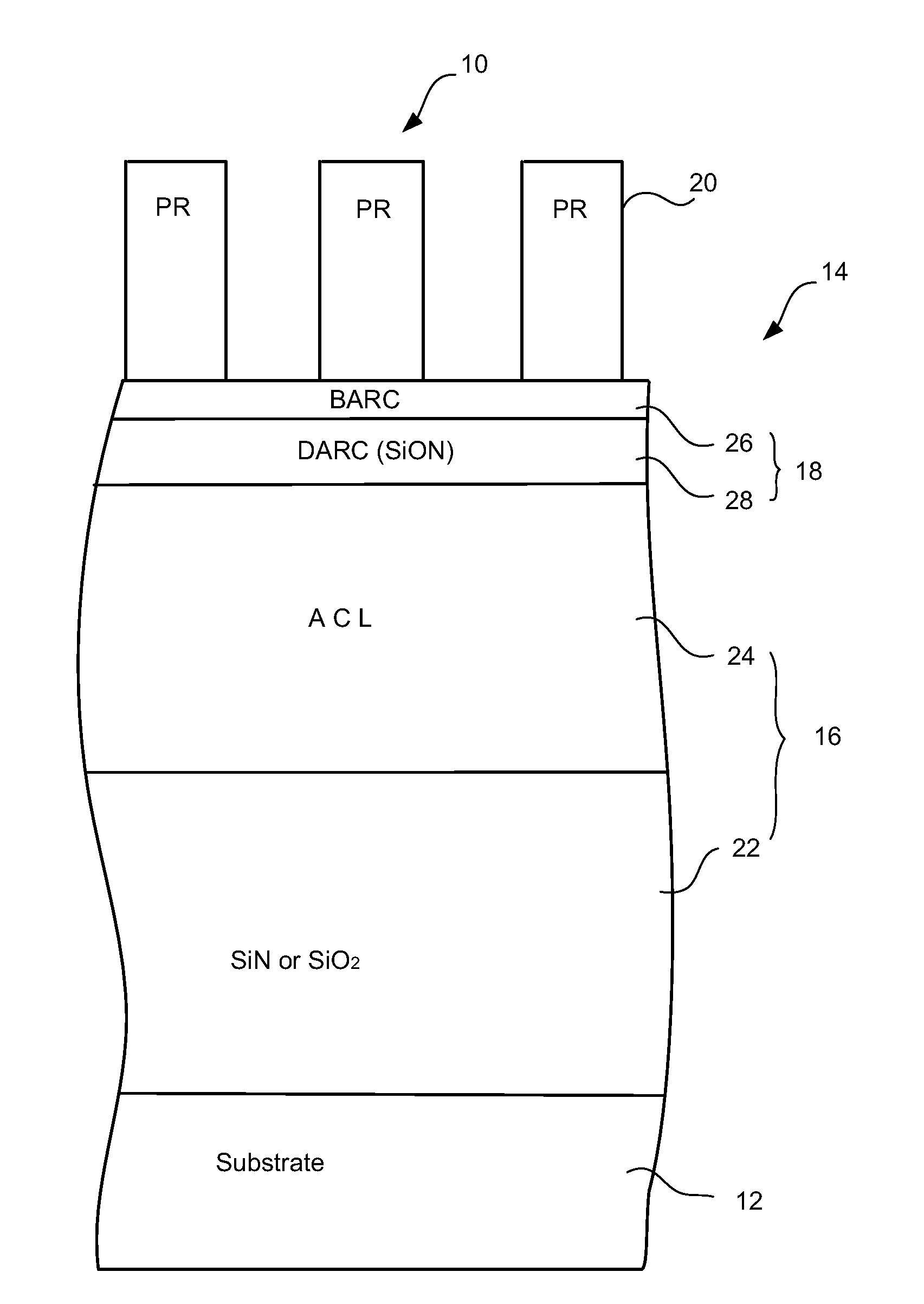

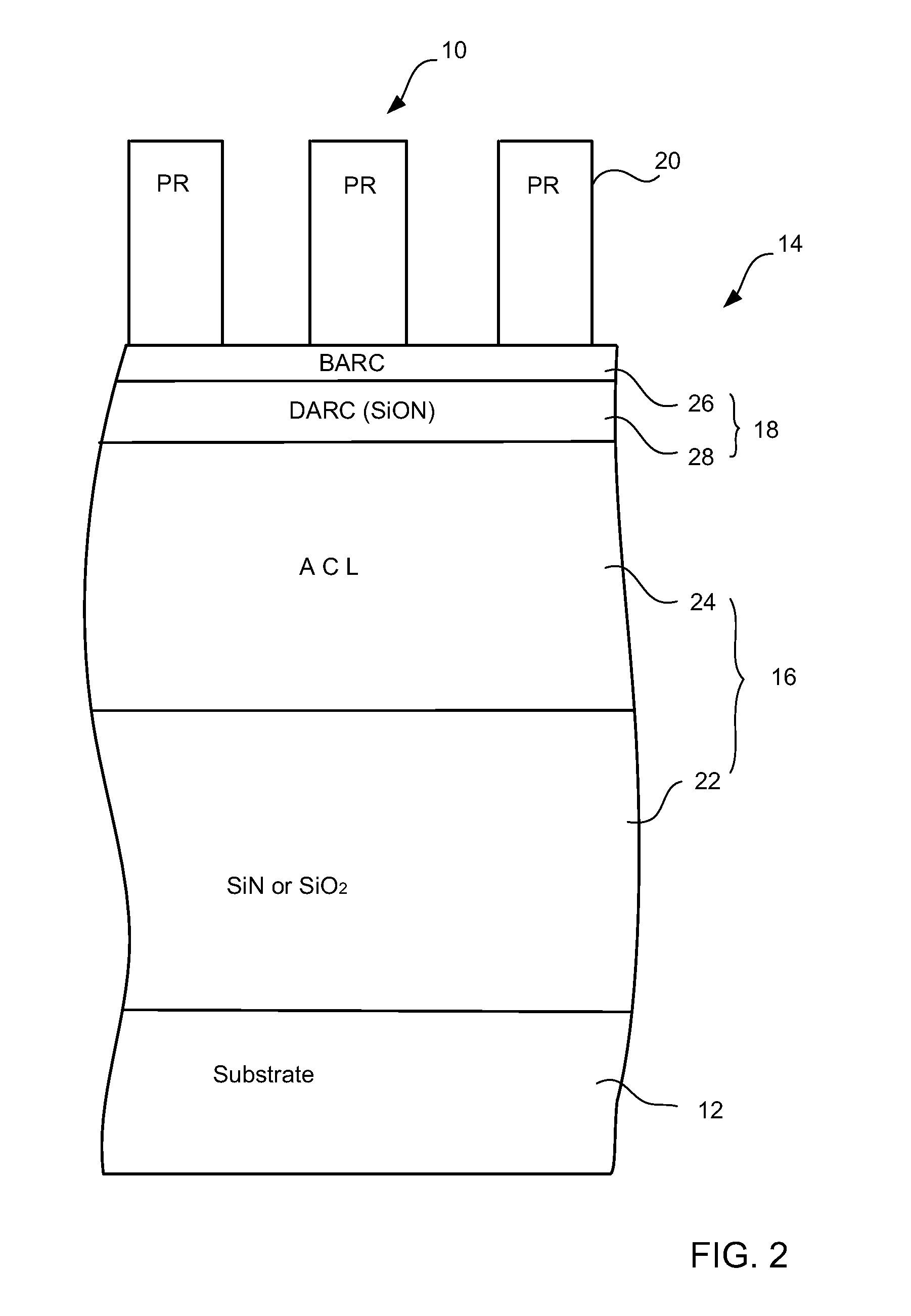

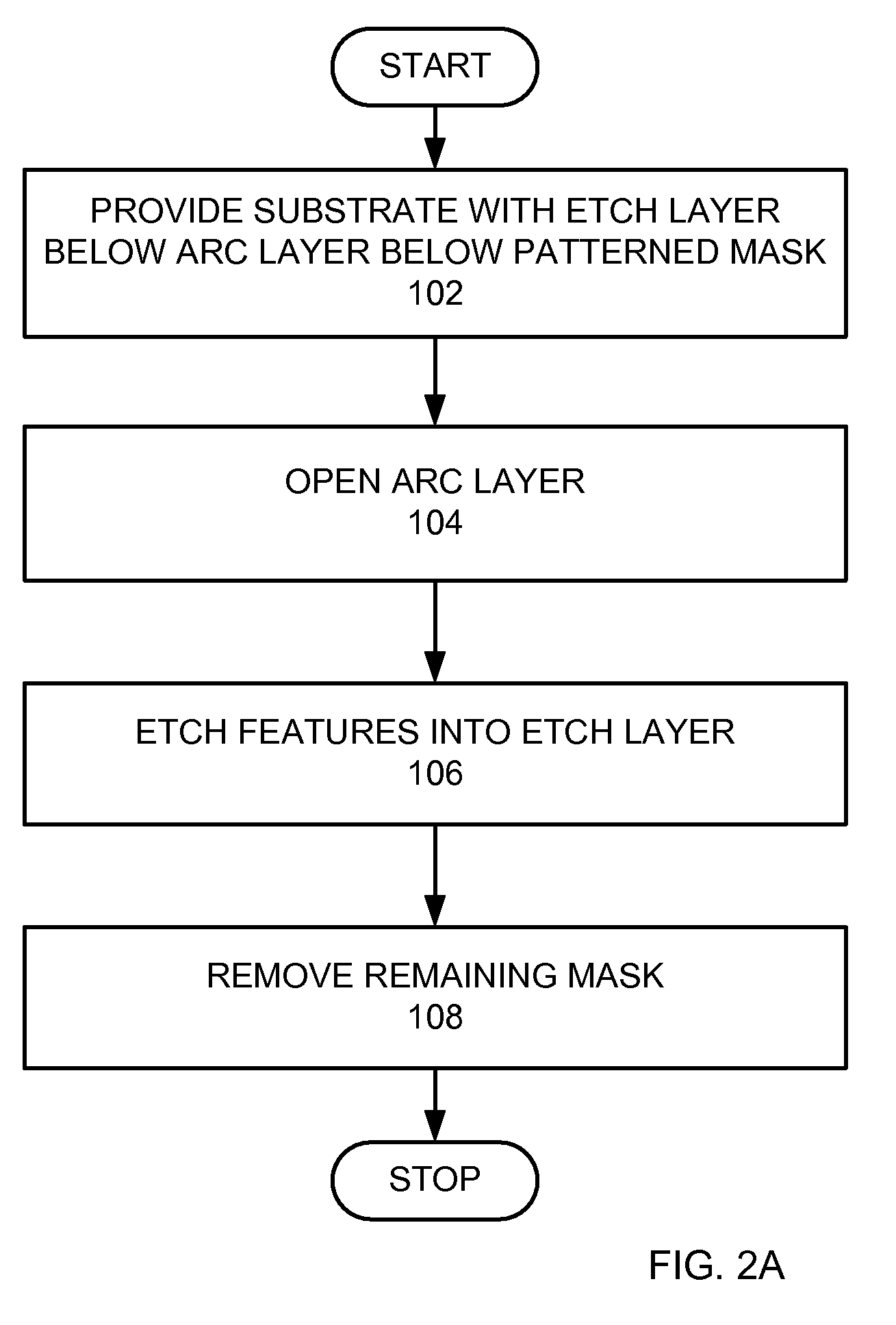

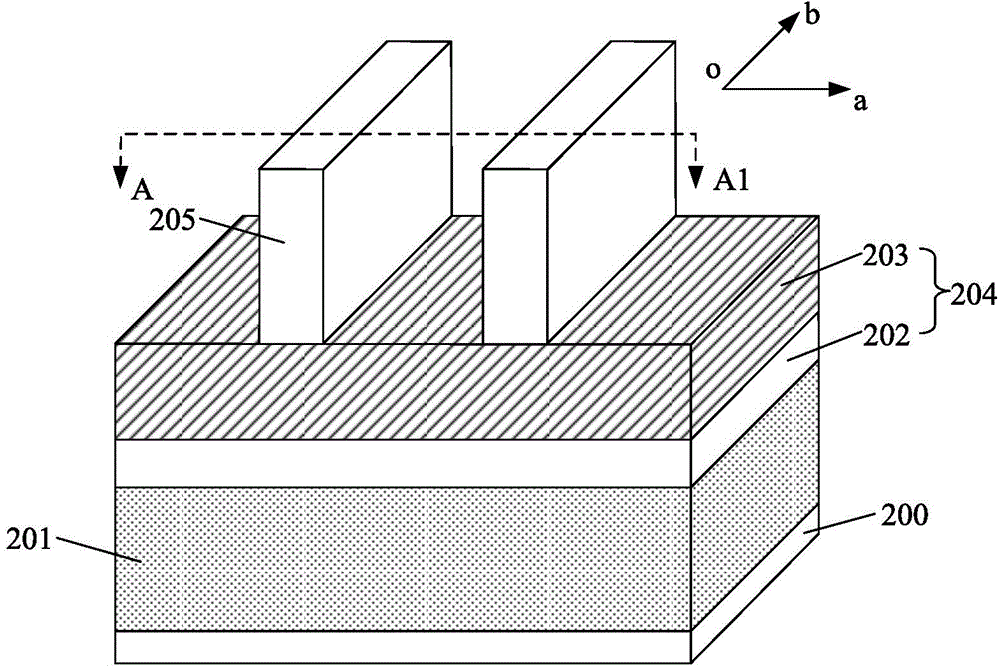

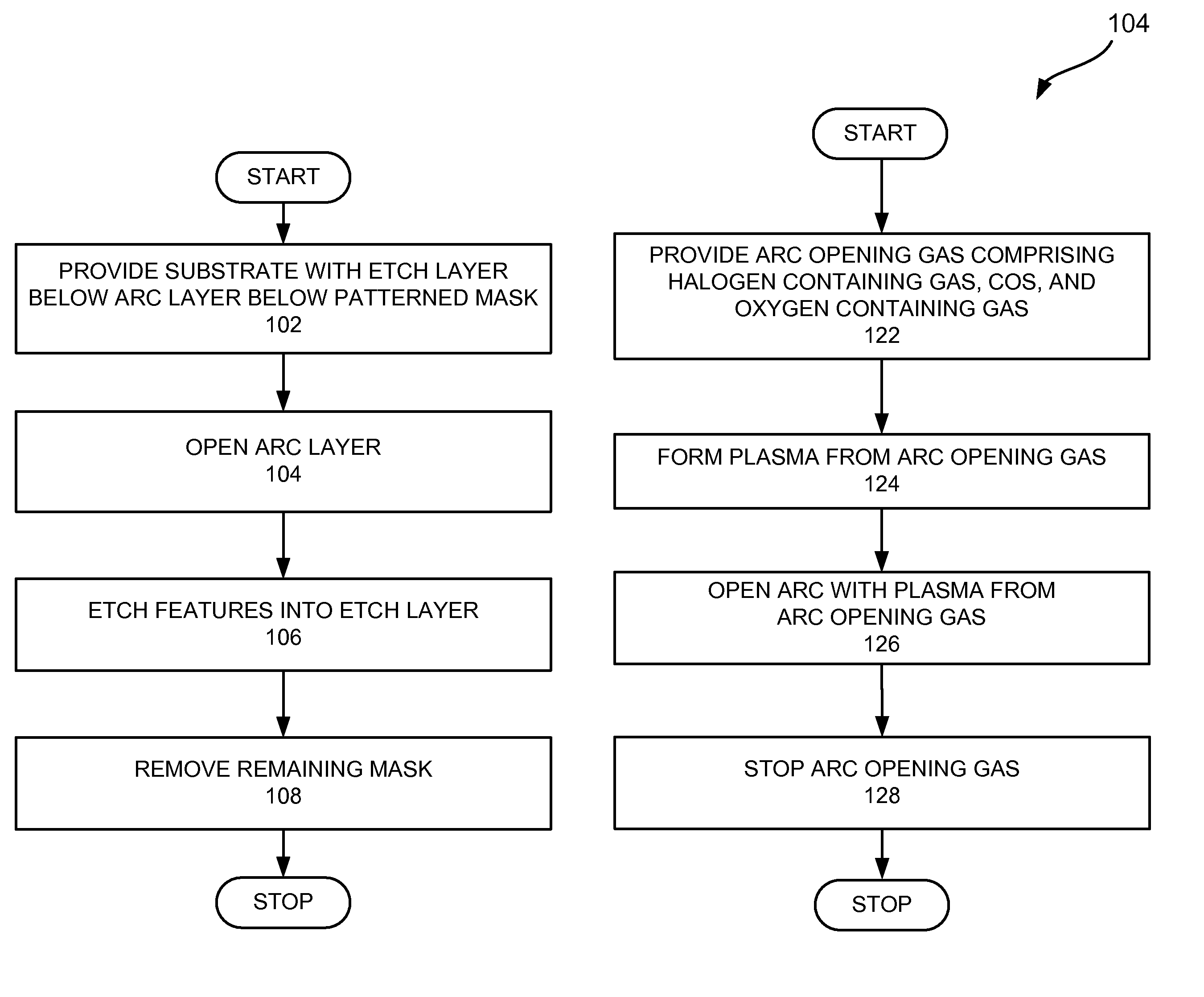

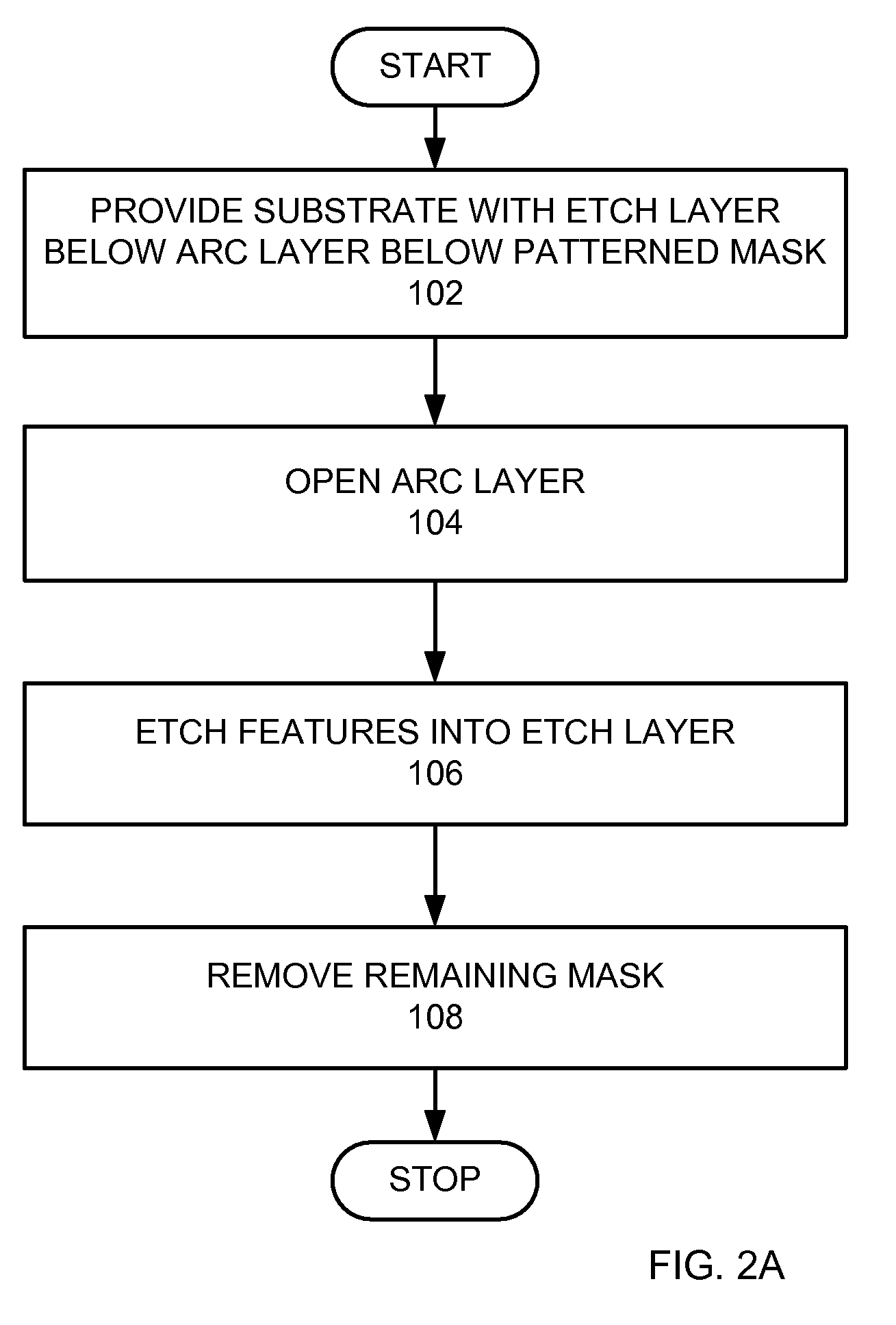

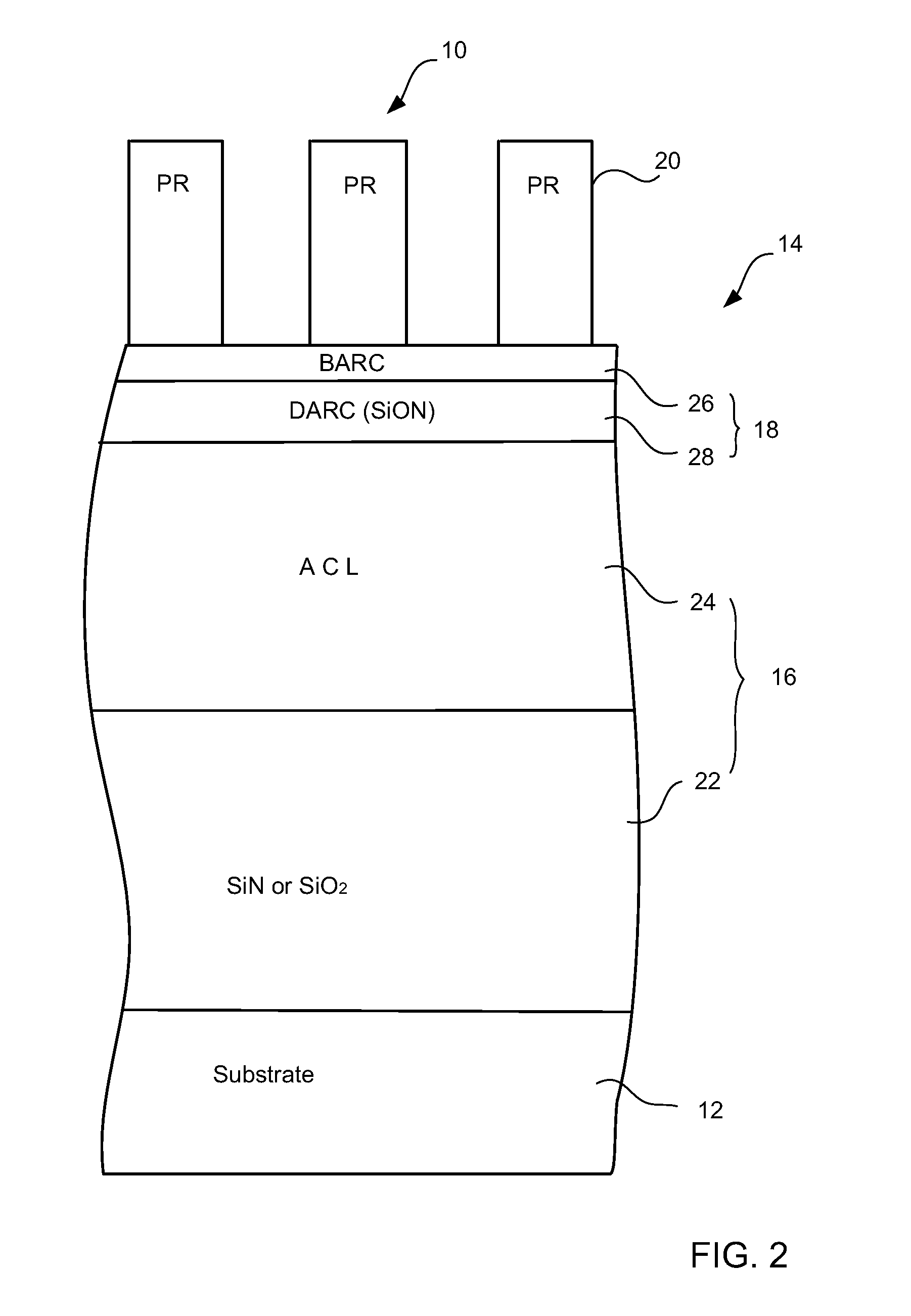

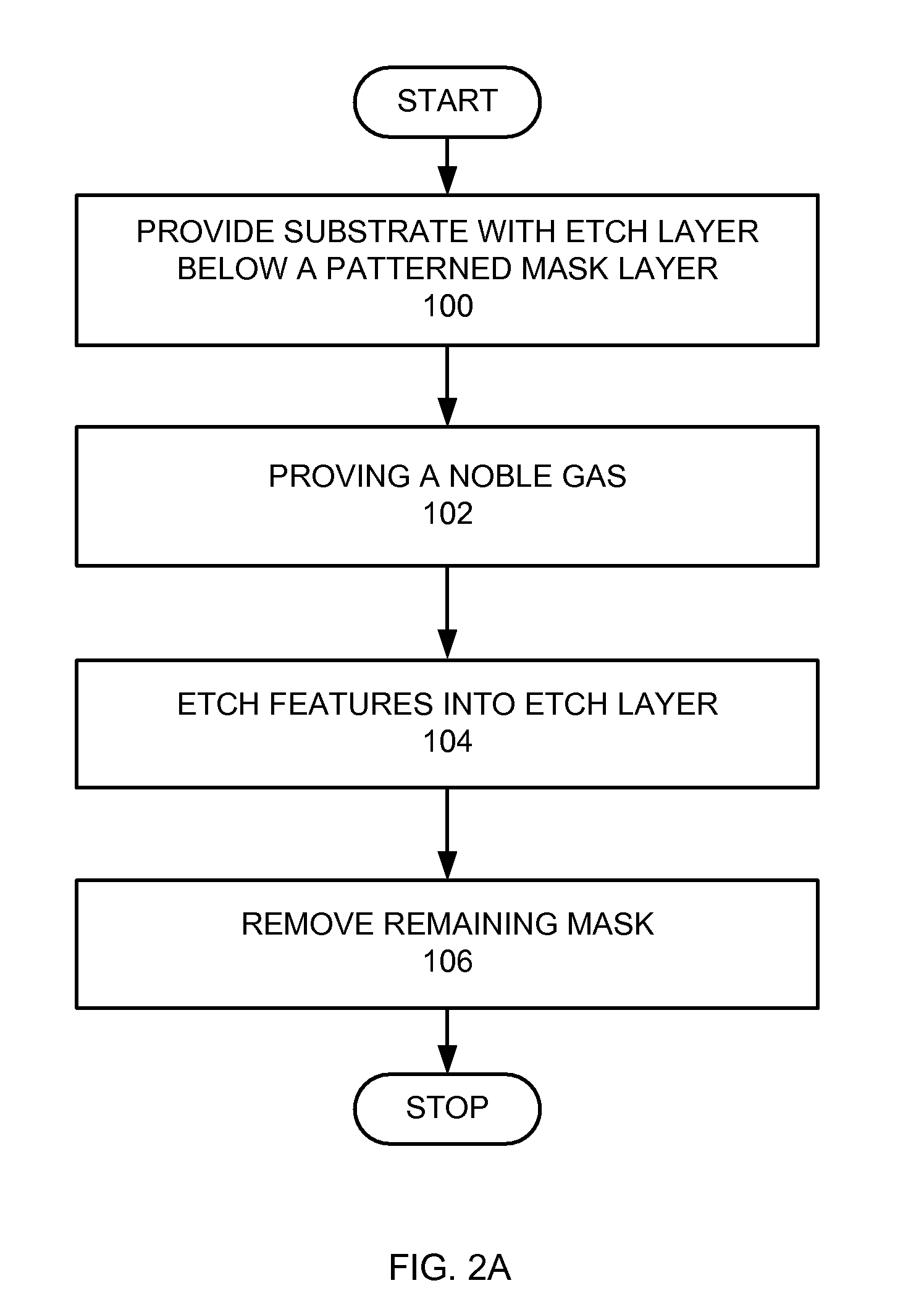

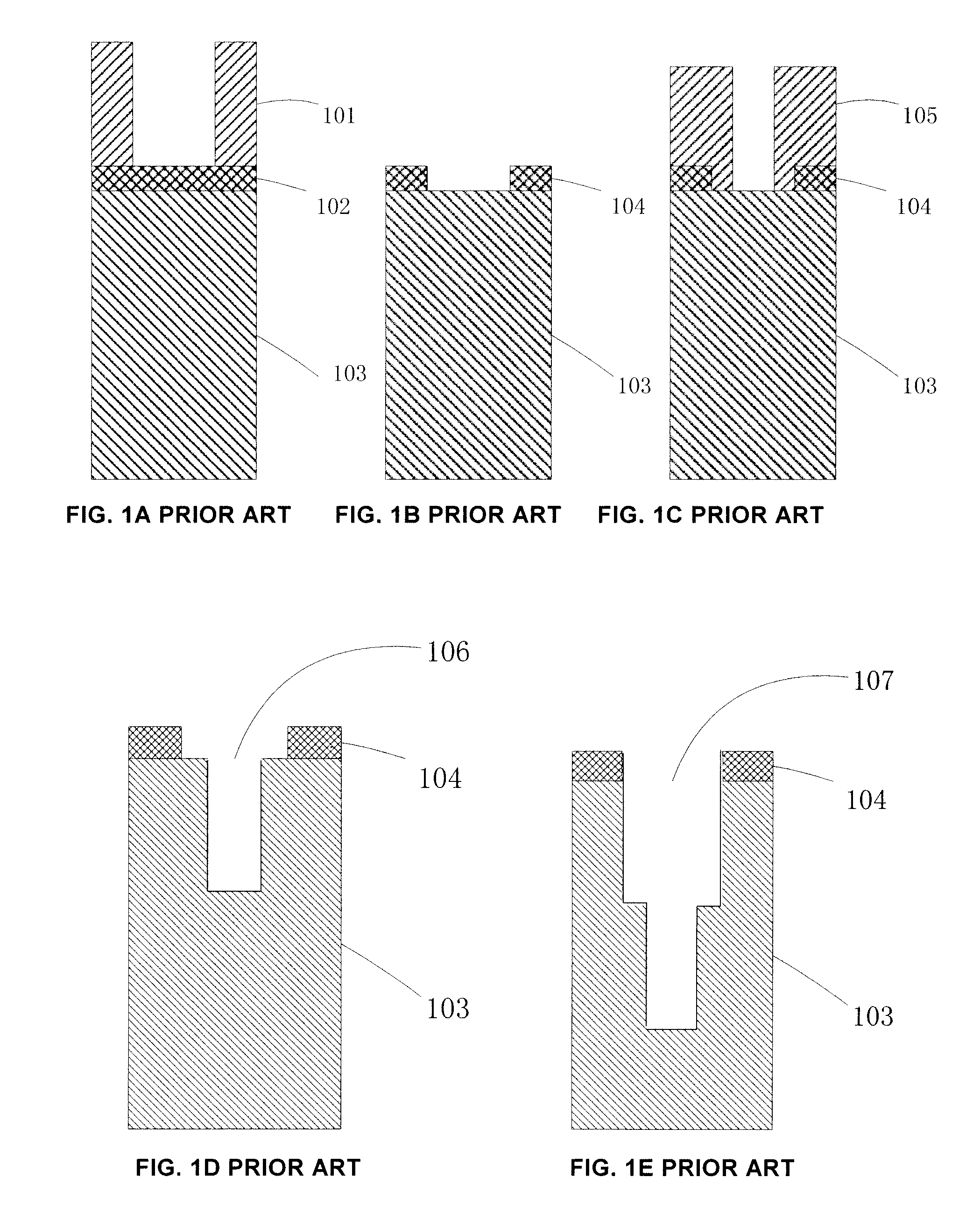

Line width roughness control with arc layer open

ActiveUS20090087996A1Reduce line width roughnessSemiconductor/solid-state device manufacturingLine widthOxygen

To achieve the foregoing and in accordance with the purpose of the present invention a method for etching an etch layer disposed below an antireflective coating (ARC) layer below a patterned mask is provided. The ARC layer is opened, and features are etched into the etch layer through the patterned mask. The opening the ARC layer includes (1) providing an ARC opening gas comprising a halogen containing gas, COS, and an oxygen containing gas, (2) forming a plasma from the ARC opening gas to open the ARC layer, and (3) stopping providing the ARC opening gas to stop the plasma. The patterned mask may be a photoresist (PR) mask having a line-space pattern. COS in the ARC opening gas reduces line width roughness (LWR) of the patterned features of the etch layer.

Owner:LAM RES CORP

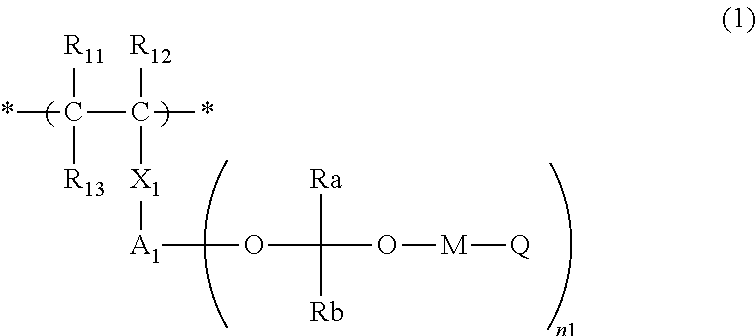

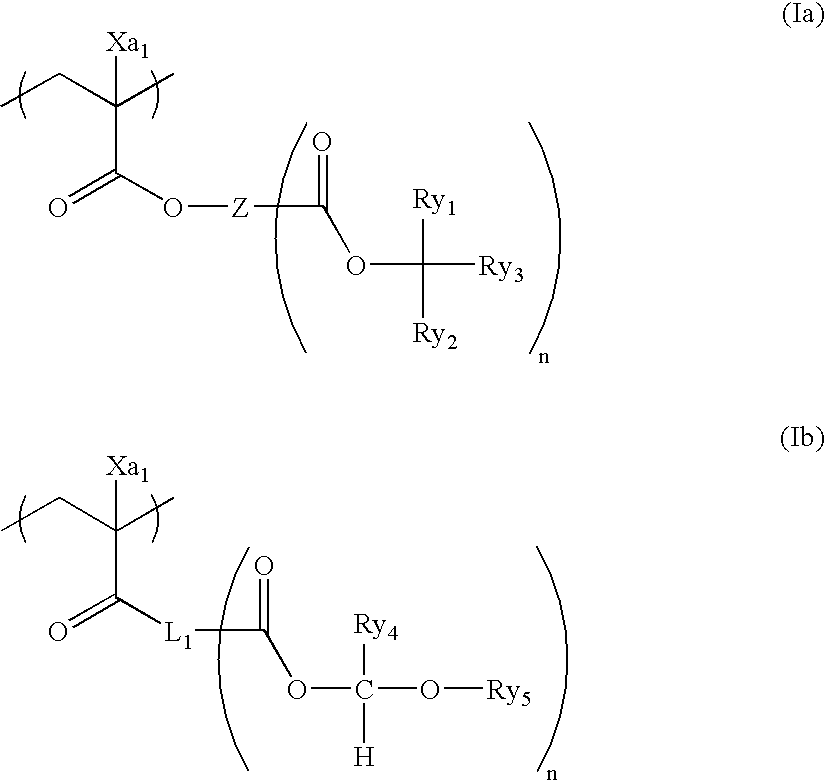

Active light sensitive or radiation sensitive composition, and resist film, pattern forming method, resist-coated mask blank, method for producing photomask, photomask, method for manufacturing electronic device, and electronic device, each of which uses said active light sensitive or radiation sensitive composition

InactiveUS20160209747A1High resolutionPattern in good shapeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusIrradiationMaterials science

There is provided an active light sensitive or radiation sensitive composition which contains (A) a compound that generates an acid by irradiation with active light or radiation, (P) a compound of which the solubility in alkali developers is increased due to the action of an acid, and (N) at least one specific compound, and which can satisfy high resolving power, an excellent pattern shape, and low line width roughness (LWR) at the same time to a high level in formation of a very fine pattern (for example, a line width of 50 nm or less), and a resist film, a pattern forming method, a resist-coated mask blank, a method for producing a photomask, a photomask, a method for manufacturing an electronic device, and an electronic device, each of which uses this active light sensitive or radiation sensitive composition.

Owner:FUJIFILM CORP

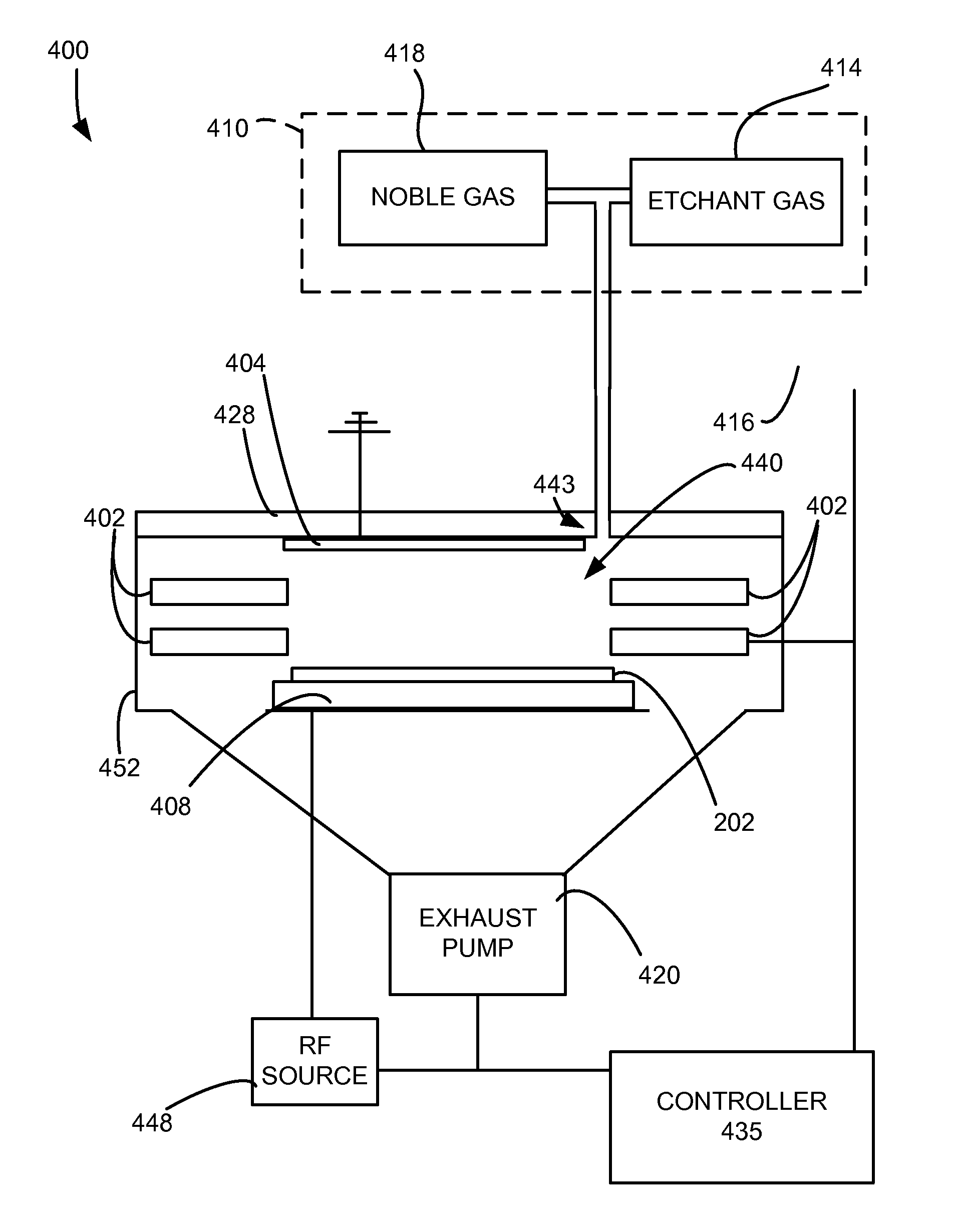

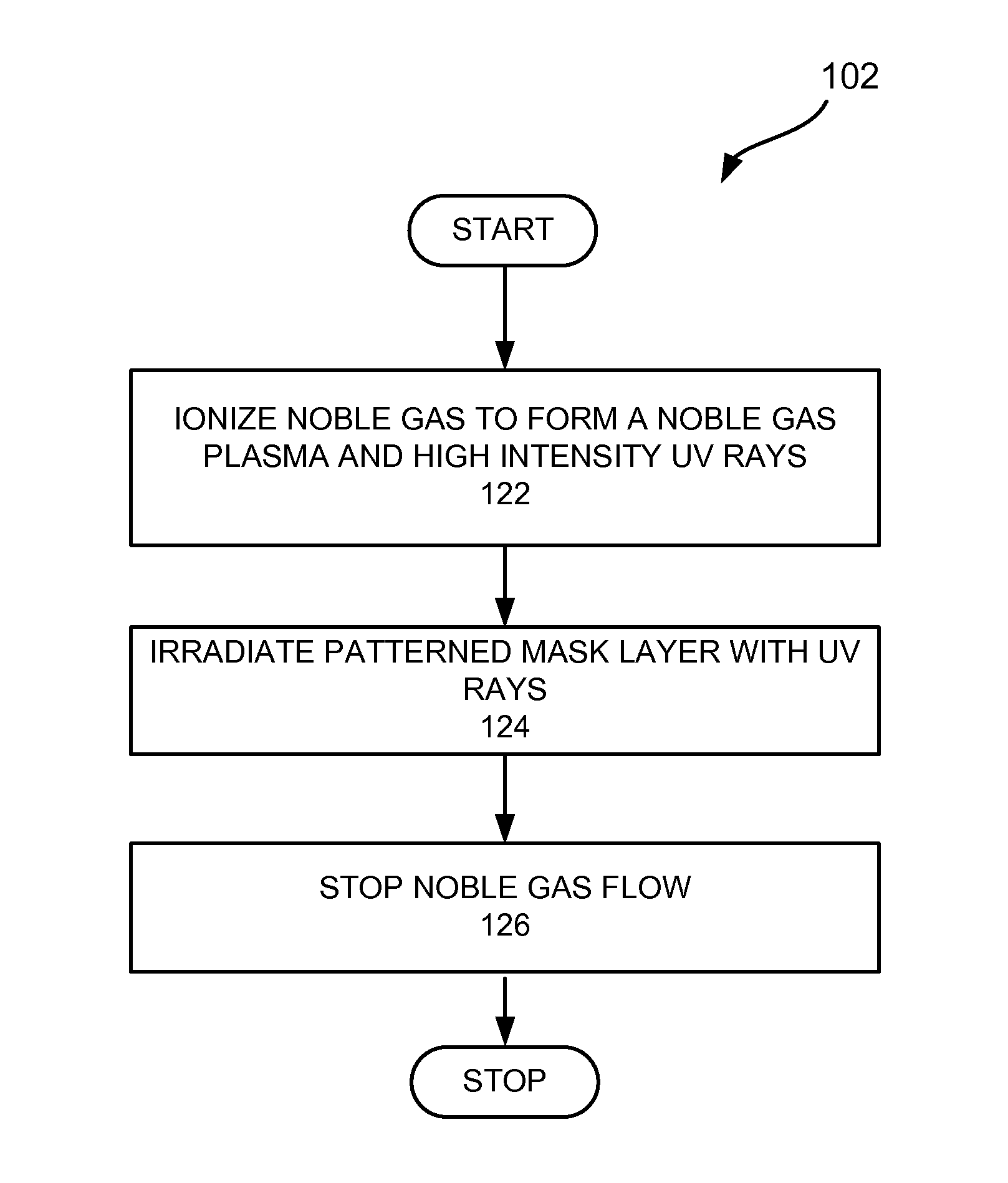

Line width roughness improvement with noble gas plasma

ActiveUS20110104616A1Reduce line width roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistNoble gas

A method for forming a photoresist mask may comprise providing a ultra-violet (UV) producing gas to a vacuum chamber having a substrate, ionizing the UV producing gas to produce UV rays to irradiate the substrate, and etching features into the substrate through the photoresist mask.

Owner:LAM RES CORP

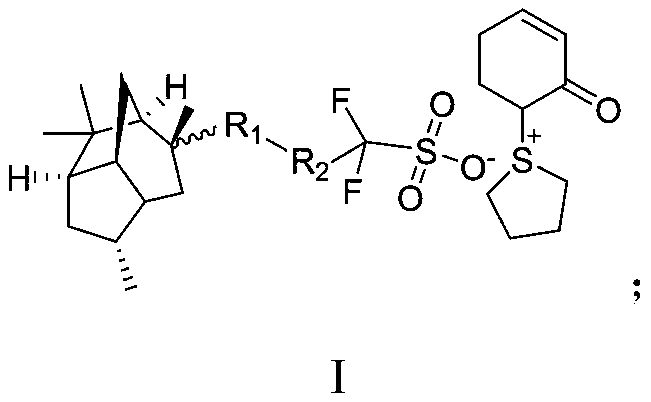

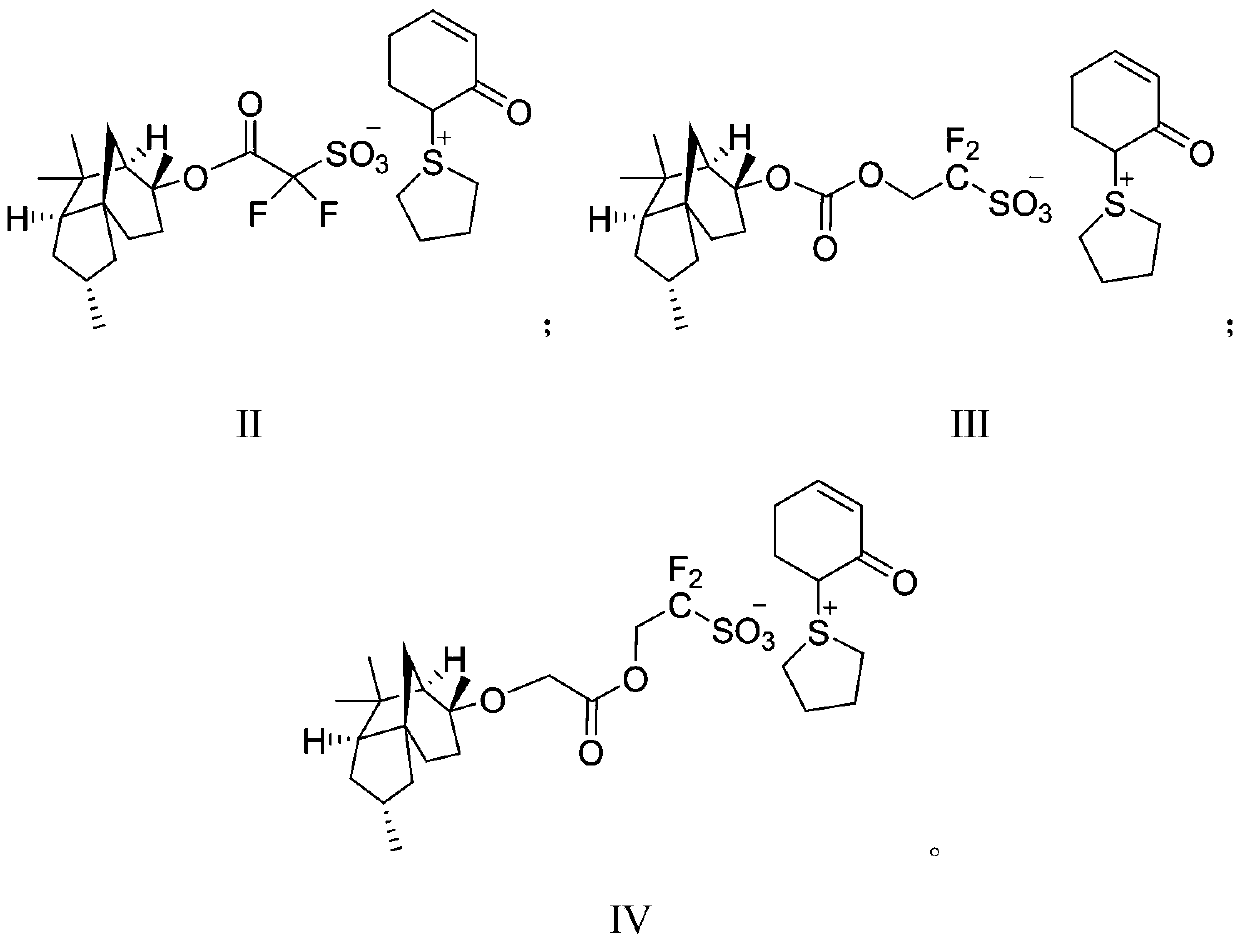

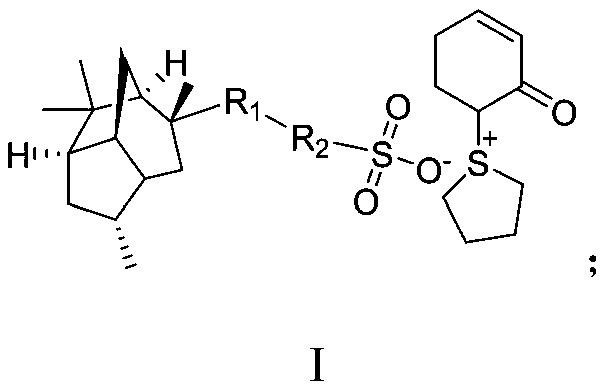

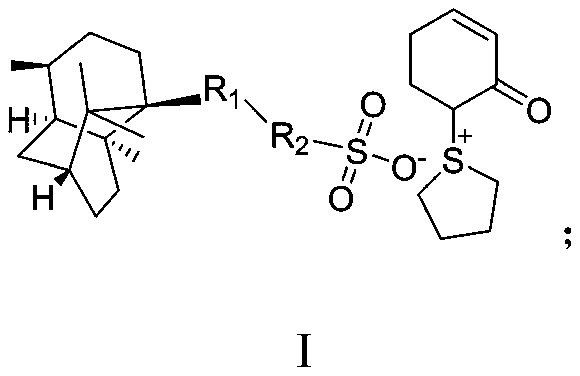

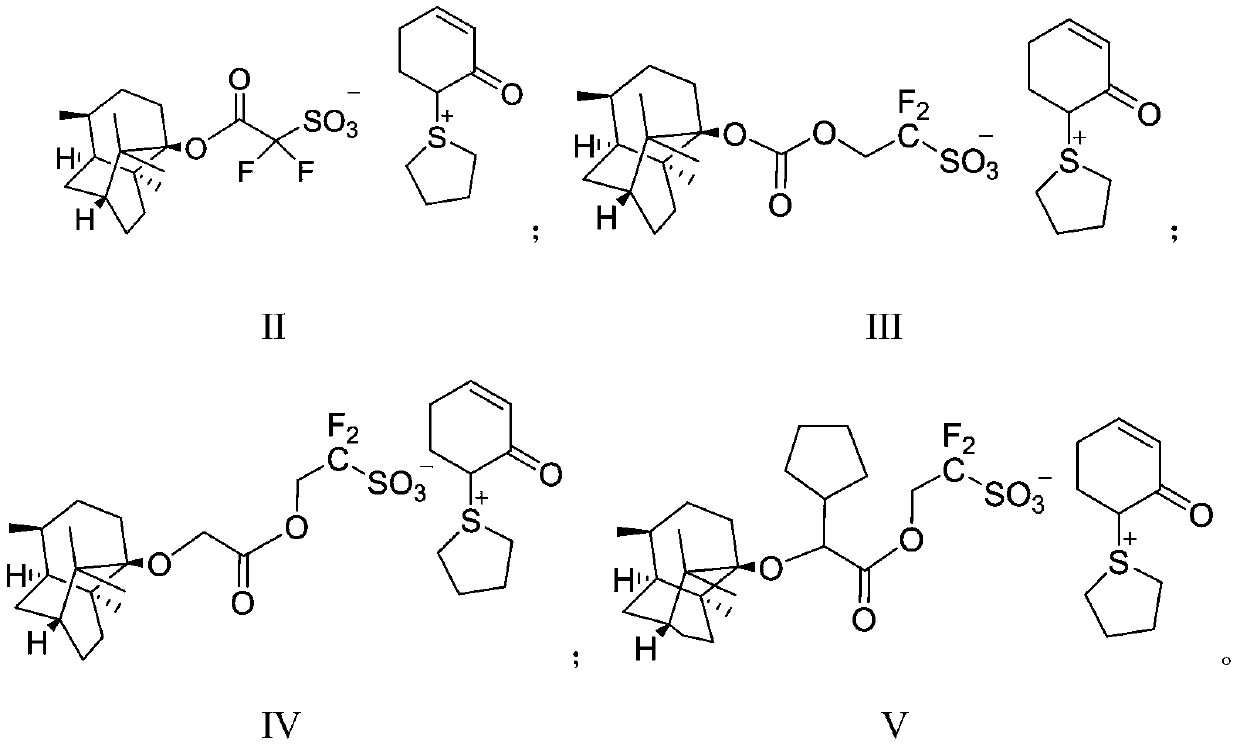

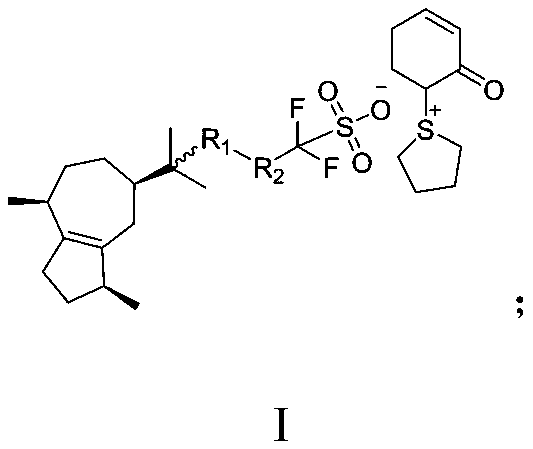

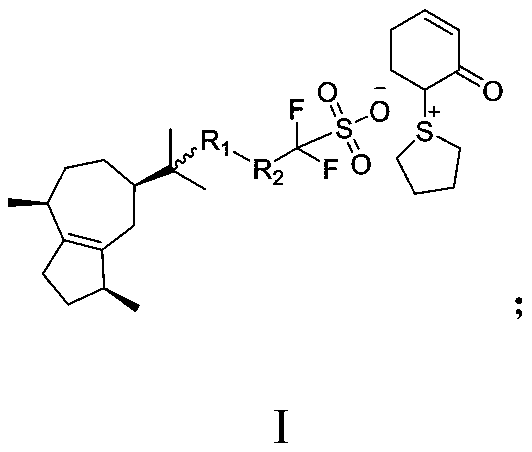

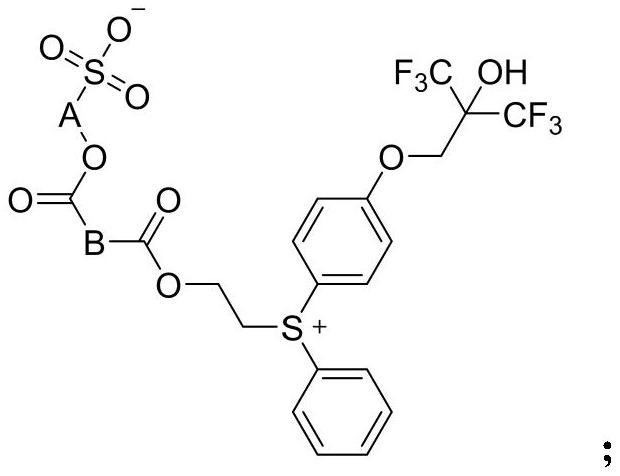

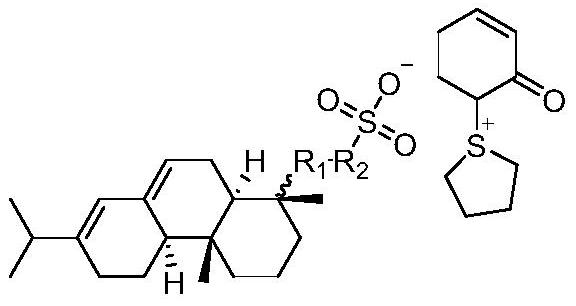

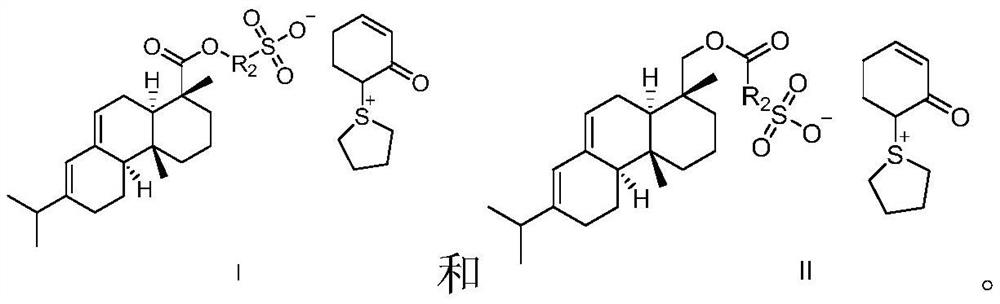

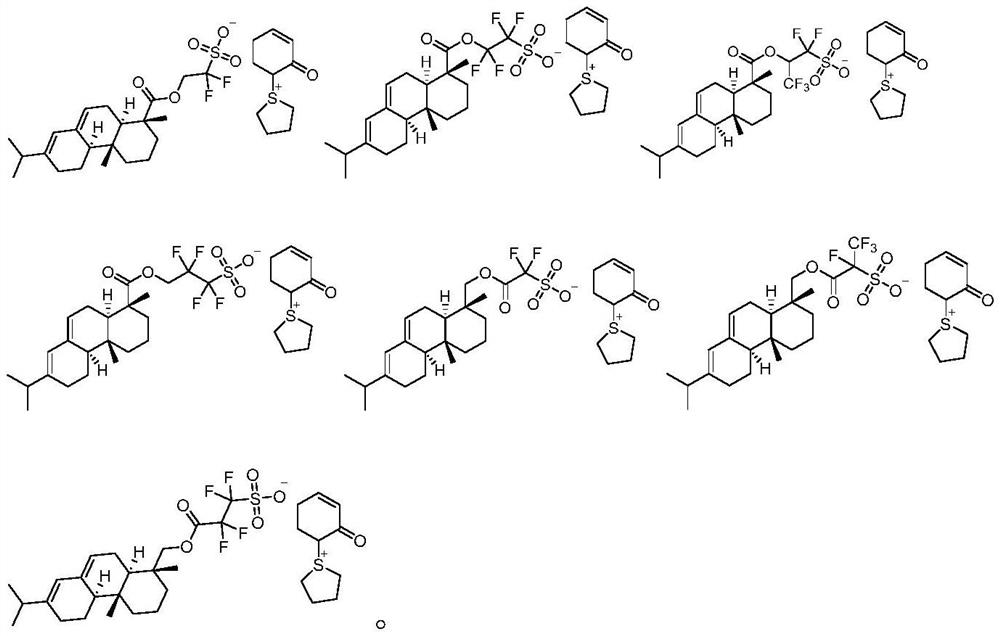

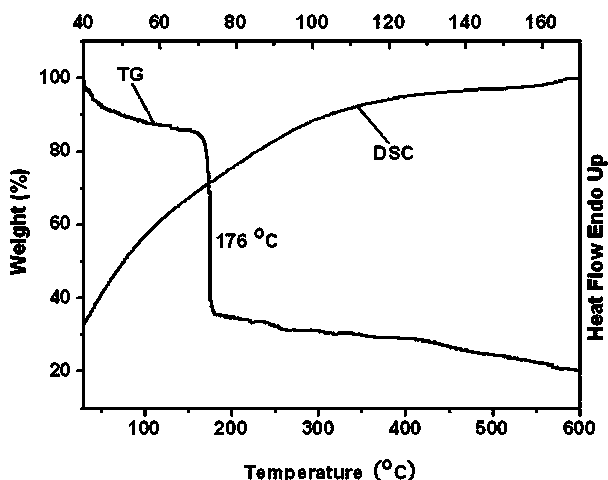

Sulfonium sulfonate salt photoacid generator synthesized from cedrol and synthesis method for sulfonium sulfonate salt photoacid generator

PendingCN111138408AImprove edge roughnessReduce line width roughnessSulfonic acids salts preparationPhotosensitive materials for photomechanical apparatusChemical synthesisTetramethylene sulfoxide

The invention discloses a sulfonium sulfonate salt photoacid generator synthesized from cedrol and a synthesis method for the sulfonium sulfonate salt photoacid generator, belonging to the fields of chemical synthesis and photoetching materials. The photoacid generator has a structural general formula which is described in the specification. In the structural general formula, R1 is one selected from the group consisting of groups which are described in the specification; and R2 is one selected from the group consisting of a covalent bond, an alkyl group, a cycloalkyl group, an ester group-containing alkyl group and a fluorine-containing alkyl group. The synthesis method for the photoacid generator comprises the following steps: allowing the cedrol to react with a sulfonate compound so as to obtain an intermediate; and allowing the intermediate to react with (cyclohexyl-1,5-dienyloxy)-trimethyl-silane, tetramethylene sulfoxide and trifluoroacetic anhydride so as to obtain the sulfoniumsulfonate salt photoacid generator. According to the invention, a raw material, namely the cedrol has large molecular weight, so the photoacid generator formed by the cedrol also has large molecular weight; diffusion of the photoacid generator can be reduced; and improvement of the edge roughness, reduction of the line width roughness and improvement of the resolution ratio are facilitated.

Owner:上海博栋化学科技有限公司

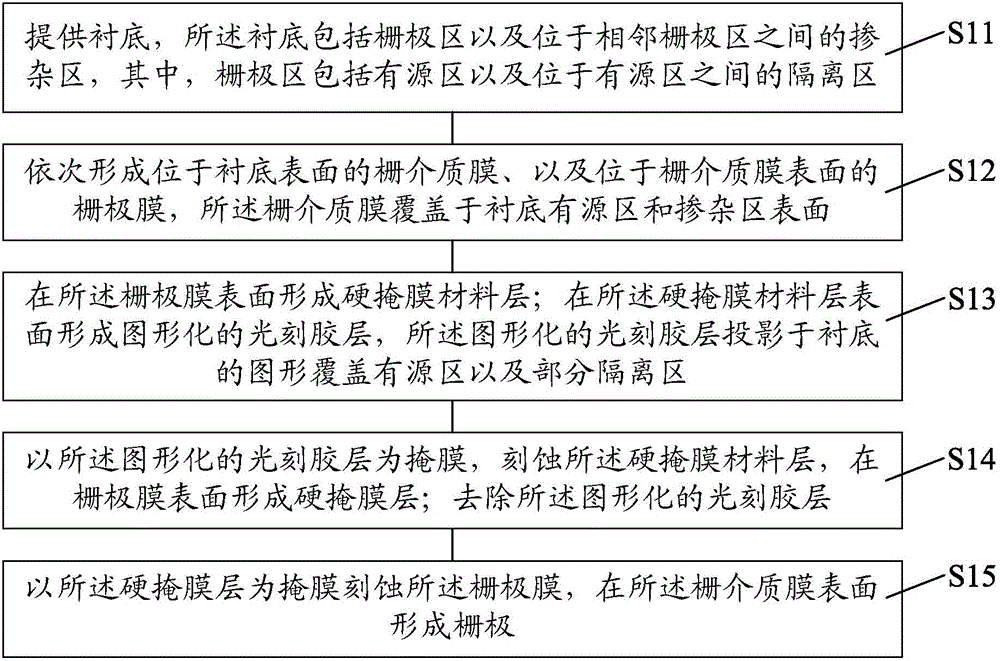

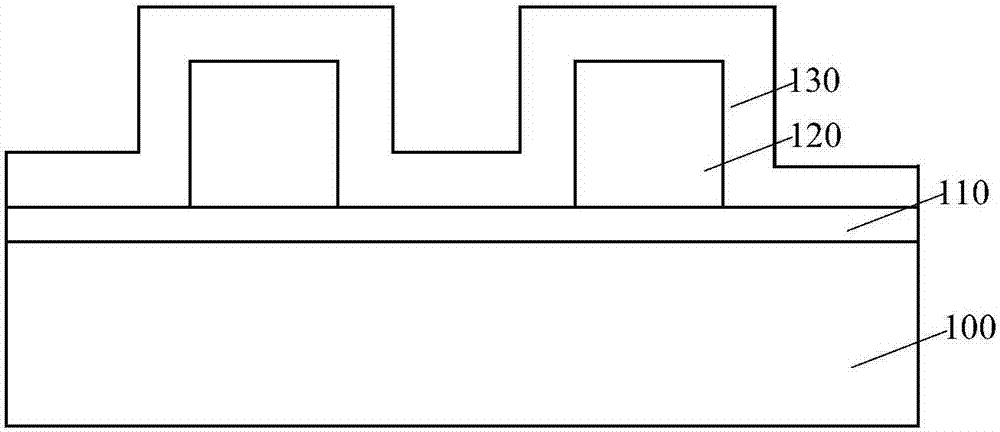

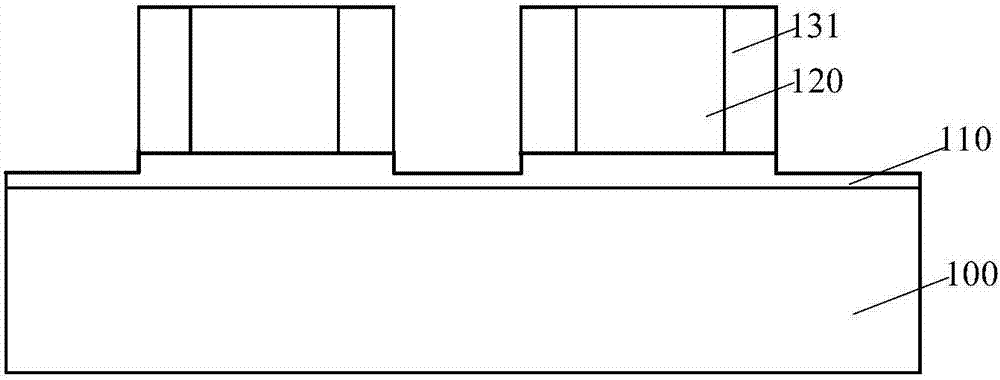

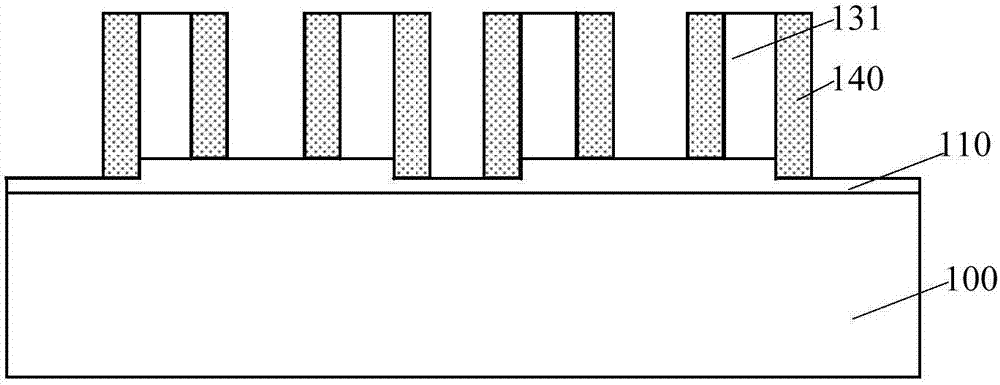

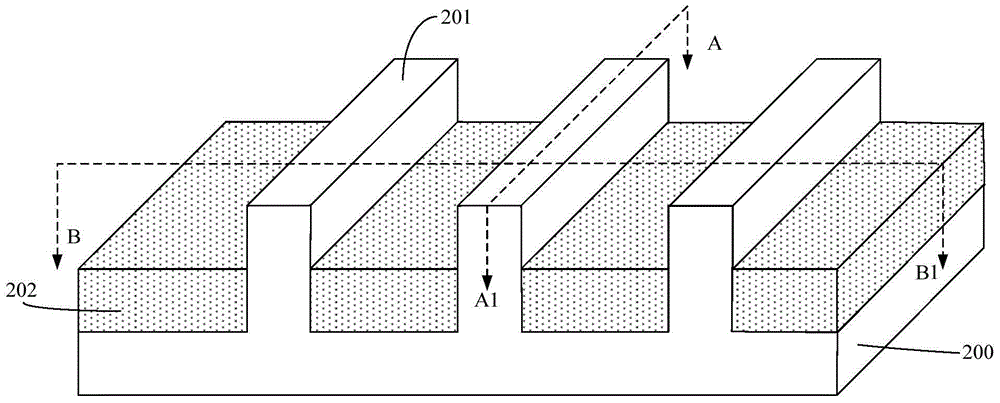

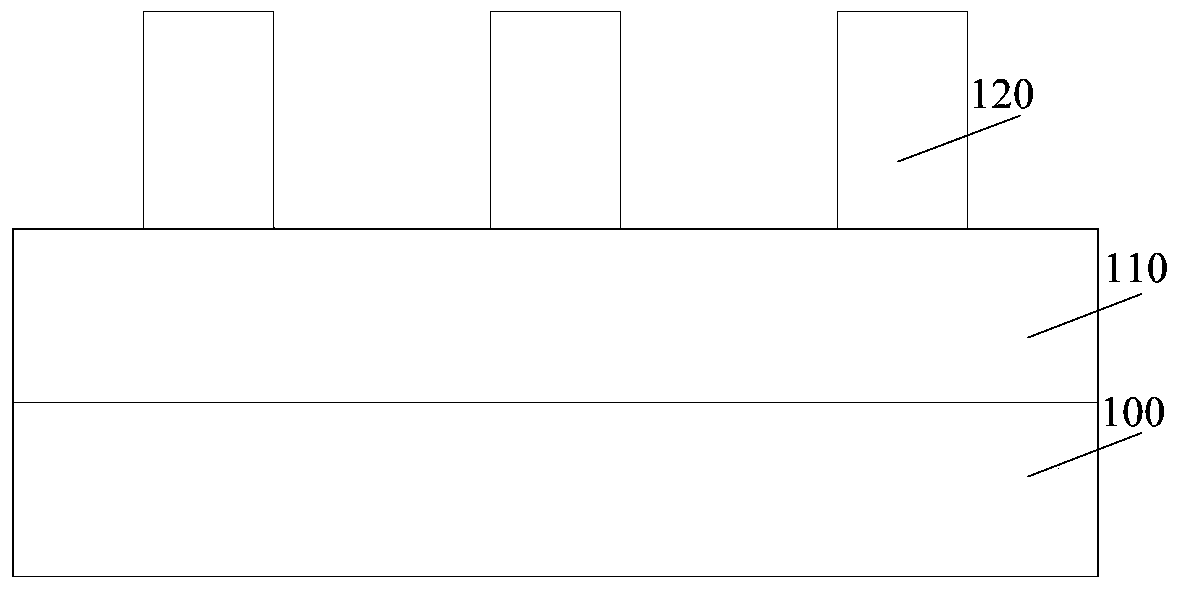

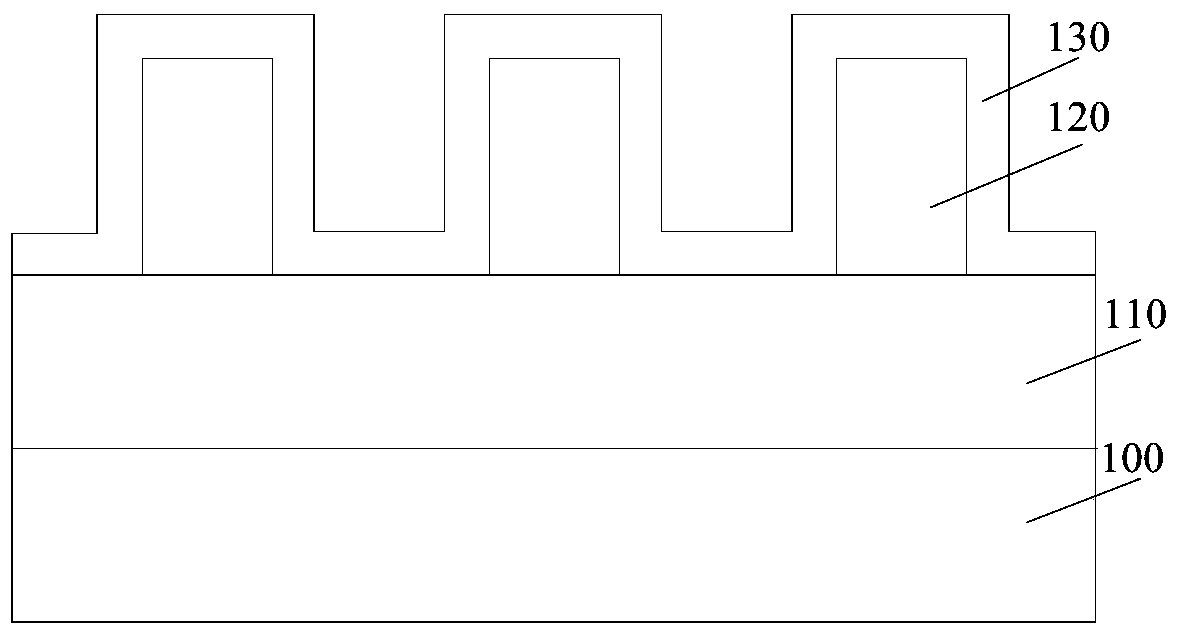

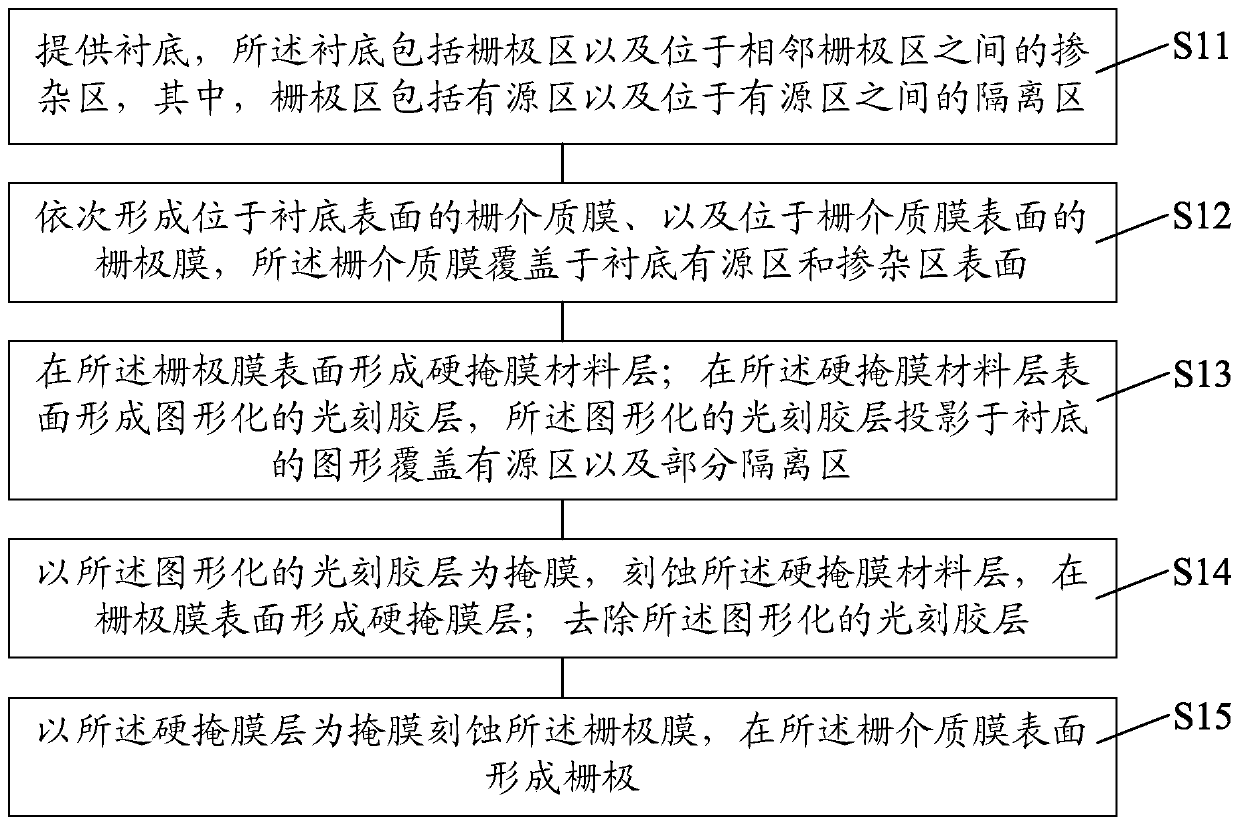

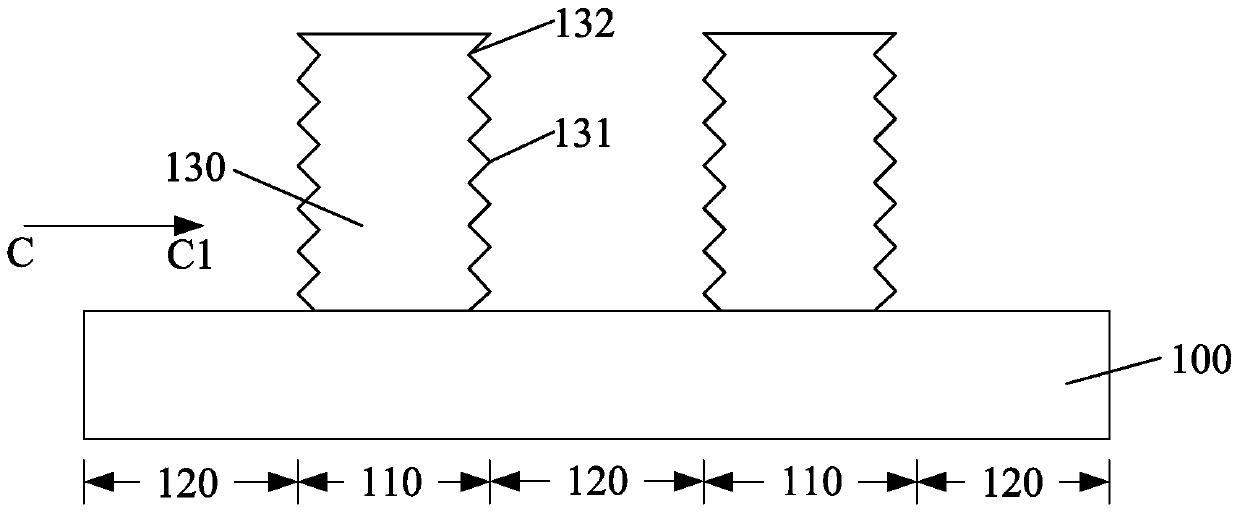

Formation method of semiconductor structure

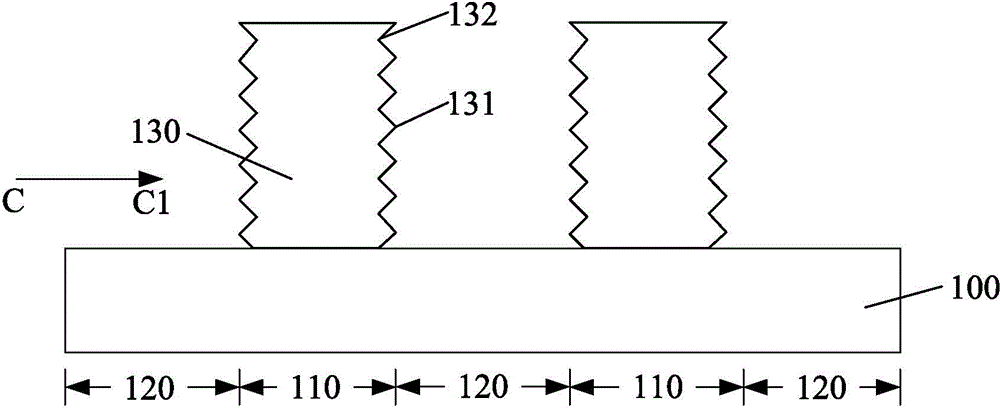

ActiveCN105575787ASmall roughnessIncreased wide roughnessSemiconductor devicesGrid patternSemiconductor structure

A formation method of a semiconductor structure is disclosed. The method comprises the following steps of providing a surface possessing a grid film substrate, wherein a grid pattern film including a hard mask layer material layer and a silicon material layer covers a grid film surface; forming a pattern layer on a grid pattern film surface; taking the pattern layer as a mask layer and etching a part of the grid pattern film to form a grid pattern layer, wherein the grid pattern layer comprises a hard mask layer and a silicon layer located on a hard mask layer surface; and a sidewall surface of the silicon layer, which is vertical to a first direction, possesses first line width roughness; carrying out repairing etching processing on the silicon layer sidewall vertical to the first direction so that the silicon layer sidewall surface possesses second line width roughness less than the first line width roughness; taking the grid pattern layer as the mask layer to etch a grid film and forming a grid on a substrate surface; and forming a source area and a leakage area in the substrate of two sides of a grid sidewall vertical to the first direction. By using the method, the line width roughness of the grid pattern layer is reduced so that formed grid quality is increased and electric performance of the semiconductor structure is optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Line width roughness control with arc layer open

ActiveUS8158524B2Reduce line width roughnessSemiconductor/solid-state device manufacturingLine widthOxygen

To achieve the foregoing and in accordance with the purpose of the present invention a method for etching an etch layer disposed below an antireflective coating (ARC) layer below a patterned mask is provided. The ARC layer is opened, and features are etched into the etch layer through the patterned mask. The opening the ARC layer includes (1) providing an ARC opening gas comprising a halogen containing gas, COS, and an oxygen containing gas, (2) forming a plasma from the ARC opening gas to open the ARC layer, and (3) stopping providing the ARC opening gas to stop the plasma. The patterned mask may be a photoresist (PR) mask having a line-space pattern. COS in the ARC opening gas reduces line width roughness (LWR) of the patterned features of the etch layer.

Owner:LAM RES CORP

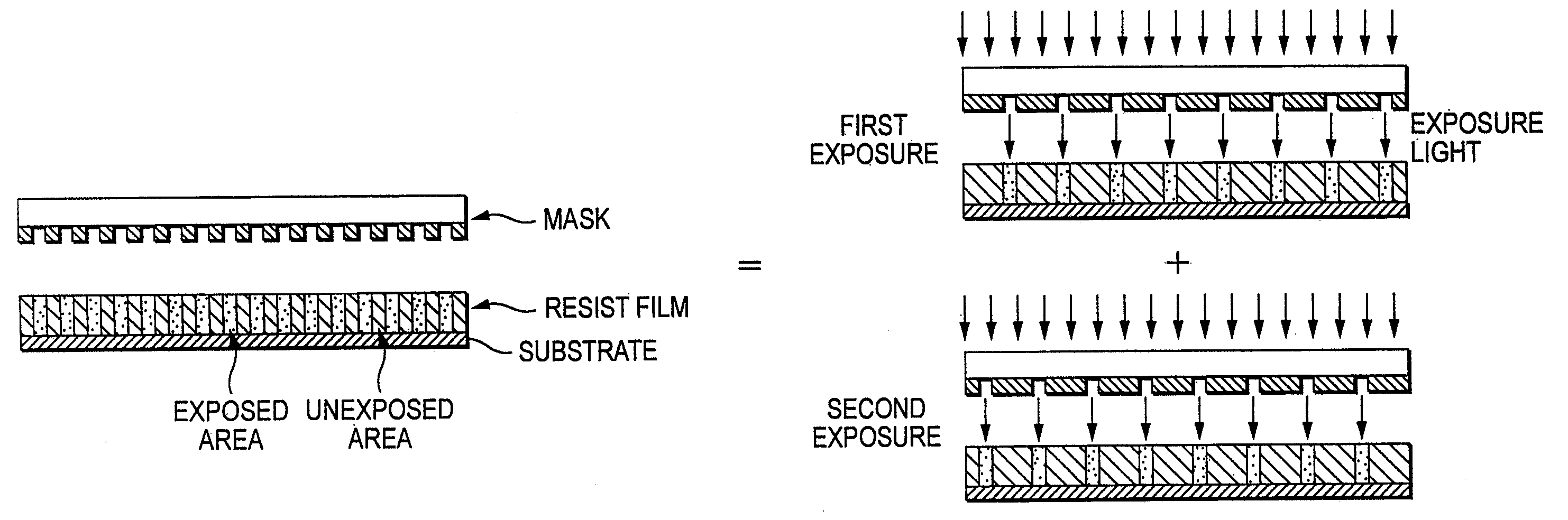

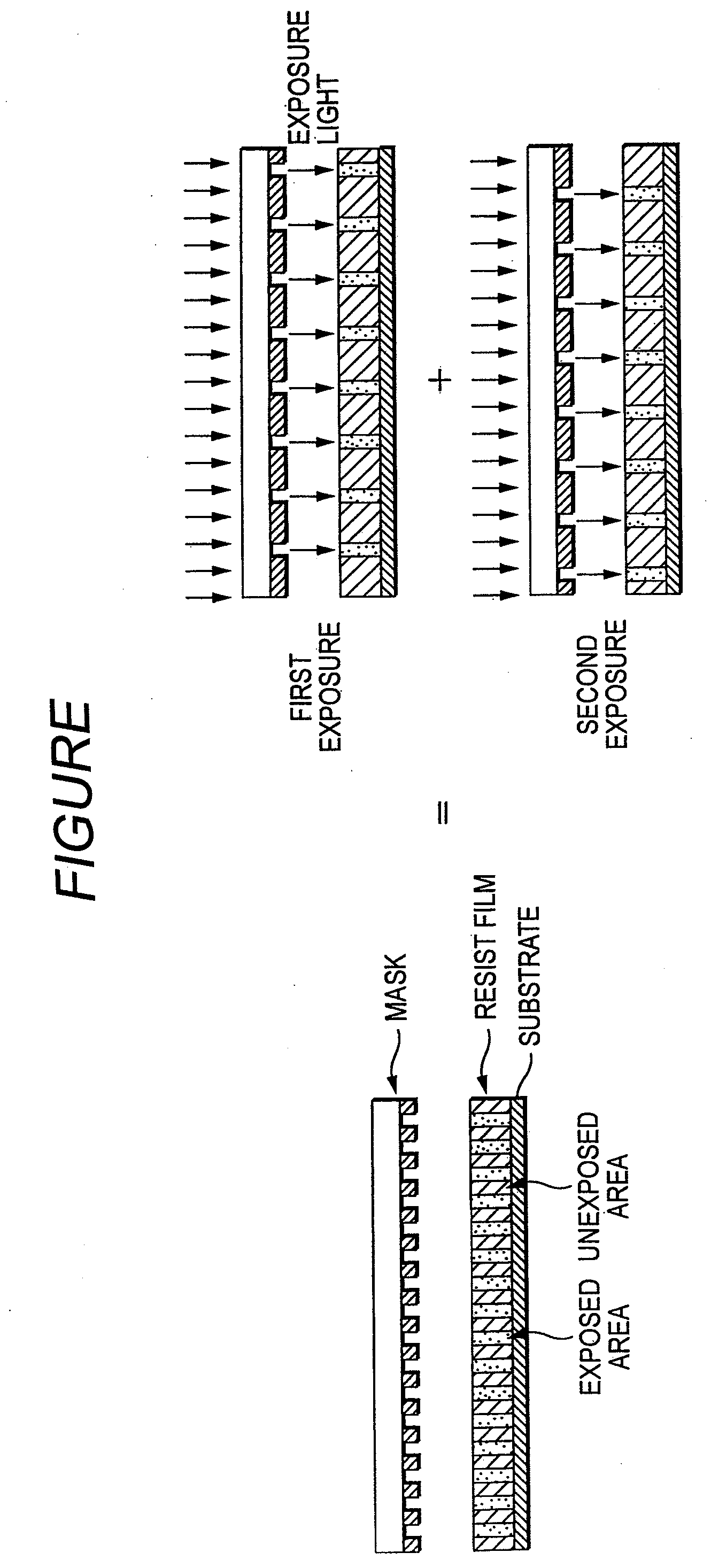

Pattern forming method

InactiveUS20090017400A1Pattern resolution be goodReduce line width roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusActinic RaysMechanical engineering

A pattern forming method, includes: exposing a resist film with actinic rays or radiation a plurality of times; and heating the resist film at a first temperature in at least one interval between the exposures.

Owner:FUJIFILM CORP

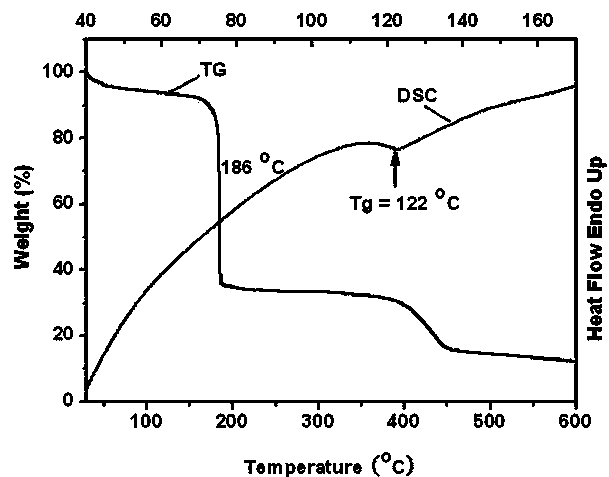

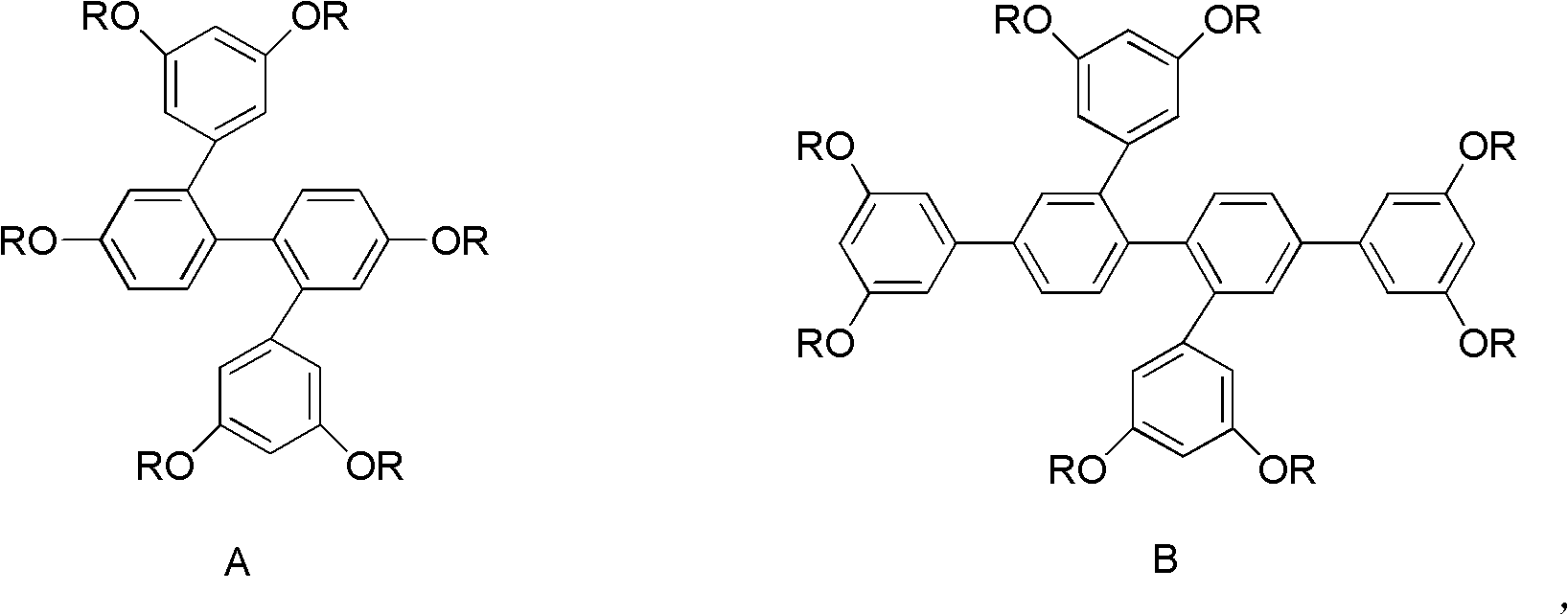

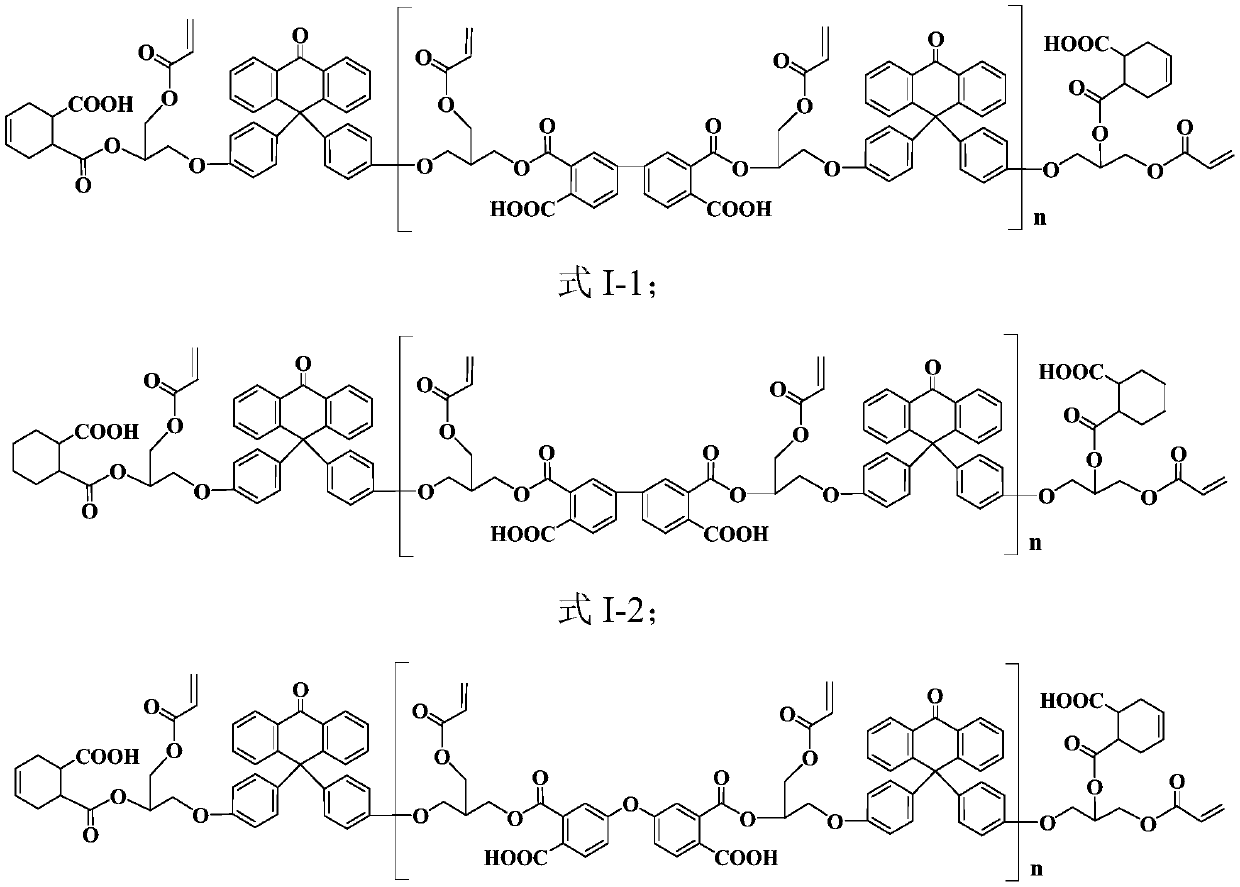

Biphenyl molecular glass and preparation method thereof

InactiveCN102557930AReduce line width roughnessNo swellingOrganic compound preparationCarboxylic acid esters preparationCompound aBenzene

The invention relates to biphenyl molecular glass and a preparation method thereof, namely preparation of 2, 2' 1 2 (3, 5-di-tert-butyl-di-carbonate)-4, 4'-1 2 (di-tert-butyl-di-carbonate) biphenyl compound A and 2, 2', 4, 4'-4 (3, 5-di-tert-butyl-di-carbonate) biphenyl compound B. The diazotization reaction is conducted on 2, 2' 1 2 (3, 5-di-tert-butyl-di-carbonate)-4, 4'-benzidine under the condition of NaNO2 / H2SO4, then the 2, 2' 1 2 (3, 5-di-tert-butyl-di-carbonate)-4, 4'-benzidine is heated and hydrolyzed under the acidity condition, demethylation is conducted under the condition of BBr3 to obtain 2, 2' 1 2 (3, 5-dyhydroxy-phenyl)-4, 4'-diphenol, and finally the 2, 2' 1 2 (3, 5-dyhydroxy-phenyl)-4, 4'-diphenol reacts with (t-Boc)2O to obtain the compound A. The 2, 2' 1 2 (3, 5-di-tert-butyl-di-carbonate)-4, 4'-benzidine is diazotized and then mixed with potassium iodide to obtain 2, 2' 1 2 (3, 5-di-tert-butyl-di-carbonate)-4, 4'-biphenyl-diiodine. The 2, 2' 1 2 (3, 5-di-tert-butyl-di-carbonate)-4, 4'-biphenyl-diiodine conducts Suzuki reaction with 3, 5-dimethoxy benzene boric acid under catalyst of Pd(Ph3)4 / K2CO3 to obtain 2, 2', 4, 4'-4(3, 5-dimethoxy) biphenyl. 2, 2', 4, 4'-4(3, 5-dyhydroxy-biphenyl) is obtained by demethylation through the BBr3 under low temperature and reacts with the (t-Boc)2O to obtain the compound B.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for reducing line width roughness with plasma pre-etch treatment on photoresist

InactiveUS8329585B2Reduce line width roughnessElectric discharge tubesDecorative surface effectsEtchingLine width

Owner:LAM RES CORP

Method of forming semiconductor device

ActiveCN107579001ALess etching lossReduce height differenceSemiconductor/solid-state device manufacturingSemiconductorMaterials science

A method for forming a semiconductor device includes the steps of providing a material layer to be etched, wherein material layer to be etched has a barrier layer; forming a plurality of discrete sacrificial layers on the surface of the barrier layer; forming a first sidewall material layer on the top surfaces and the sidewall surfaces of the sacrificial layers, and the surface of the barrier layer; etching the first sidewall material layer until exposing the surface of the barrier layer and top surfaces of the sacrificial layers, forming a first side wall on the sidewalls of the sacrificial layers, with an etching selection ratio of the first sidewall material layer to the barrier layer being greater than or equal to 10; and after removing the sacrificial layers, etching the barrier layerand the material to be etched by using the first sidewall as a mask. The method of forming the semiconductor device improves the performance of the patterns in the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

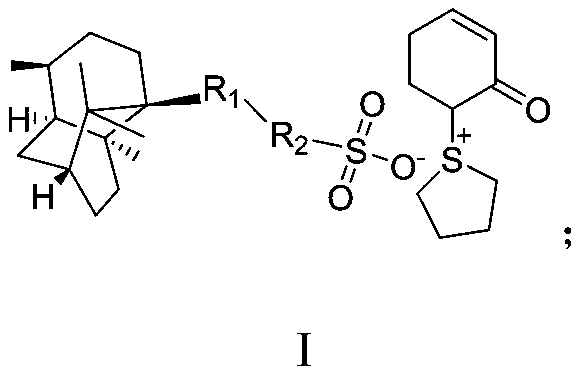

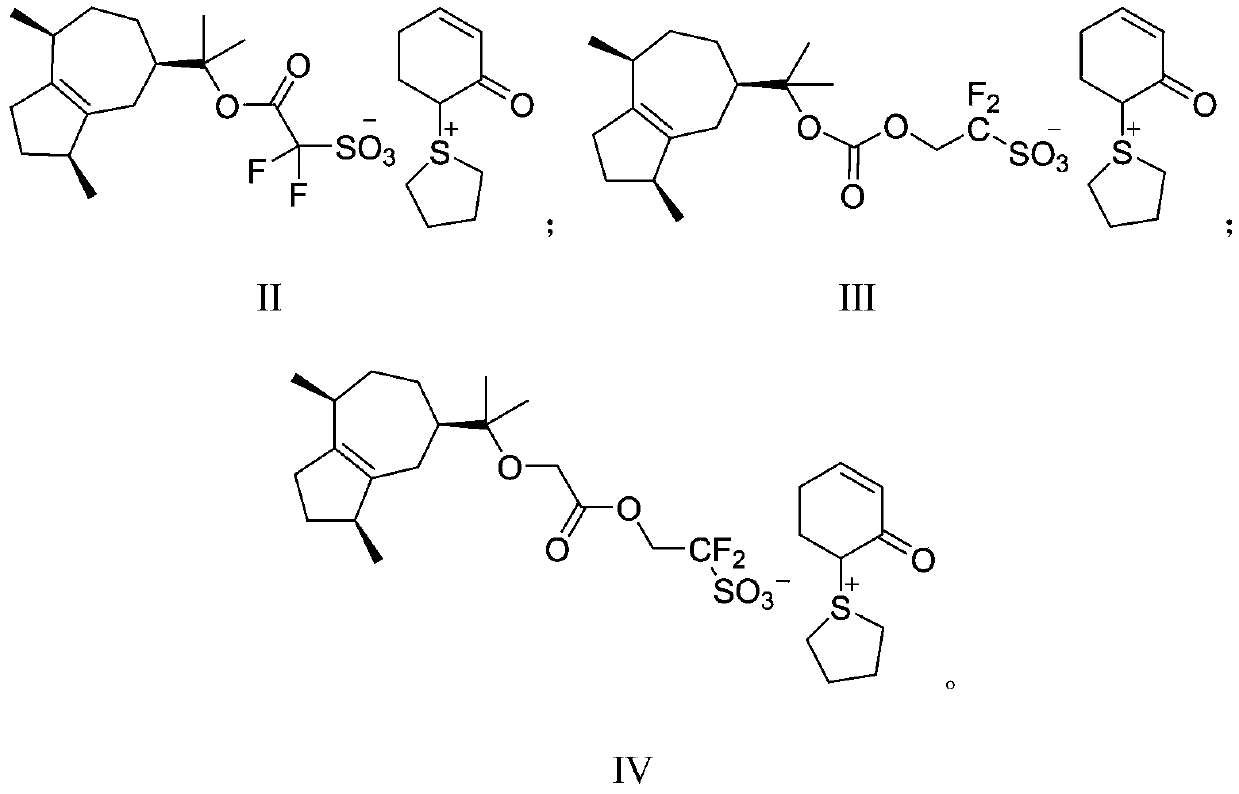

Sulfonium sulfonate salt photoacid generator synthesized from patchouli alcohol and synthesis method for sulfonium sulfonate salt photoacid generator

PendingCN111138405AReduce spreadHigh molecular weightOrganic chemistry methodsSulfonic acids salts preparationChemical synthesisSilanes

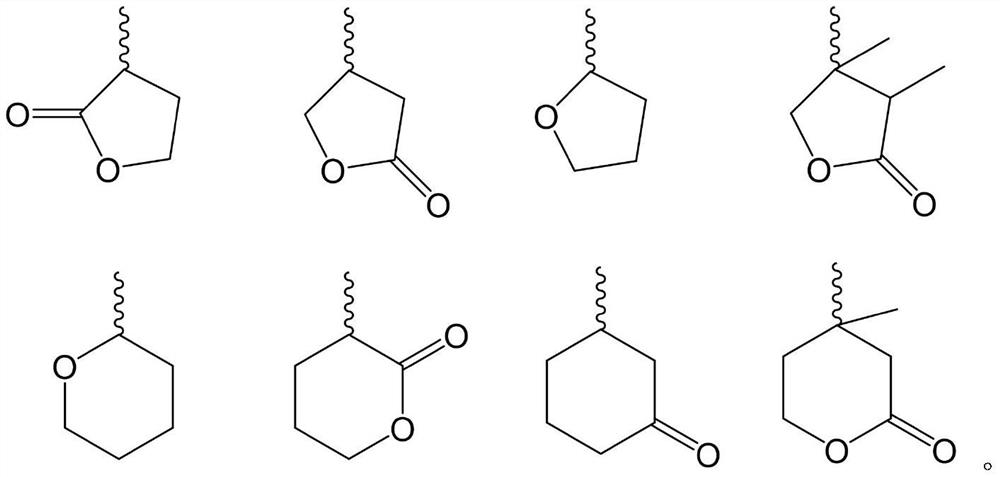

The invention discloses a sulfonium sulfonate salt photoacid generator synthesized from patchouli alcohol and a synthesis method for the sulfonium sulfonate salt photoacid generator, belonging to thefields of chemical synthesis and photoetching materials. The photoacid generator has a structural general formula which is described in the specification. In the structural general formula, R1 is oneselected from the group consisting of groups which are described in the specification; and R2 is one selected from the group consisting of an alkyl group, a cycloalkyl group, a heteroalkyl group, a heterocycloalkyl group, an ester group-containing alkyl group and a fluorine-containing alkyl group. The synthesis method for the photoacid generator comprises the following steps: allowing the patchouli alcohol to react with a sulfonate compound so as to obtain an intermediate; allowing the intermediate to react with (cyclohexyl-1,5-dienyloxy)-trimethyl-silane, tetramethylene sulfoxide and trifluoroacetic anhydride so as to obtain the sulfonium sulfonate salt photoacid generator. According to the invention, a raw material, namely the patchouli alcohol adopted in the method provided by the invention has large molecular weight, so the photoacid generator formed by the patchouli alcohol also has large molecular weight; diffusion of the photoacid generator can be reduced; and improvement of theedge roughness, reduction of the line width roughness and improvement of the resolution ratio are facilitated.

Owner:上海博栋化学科技有限公司

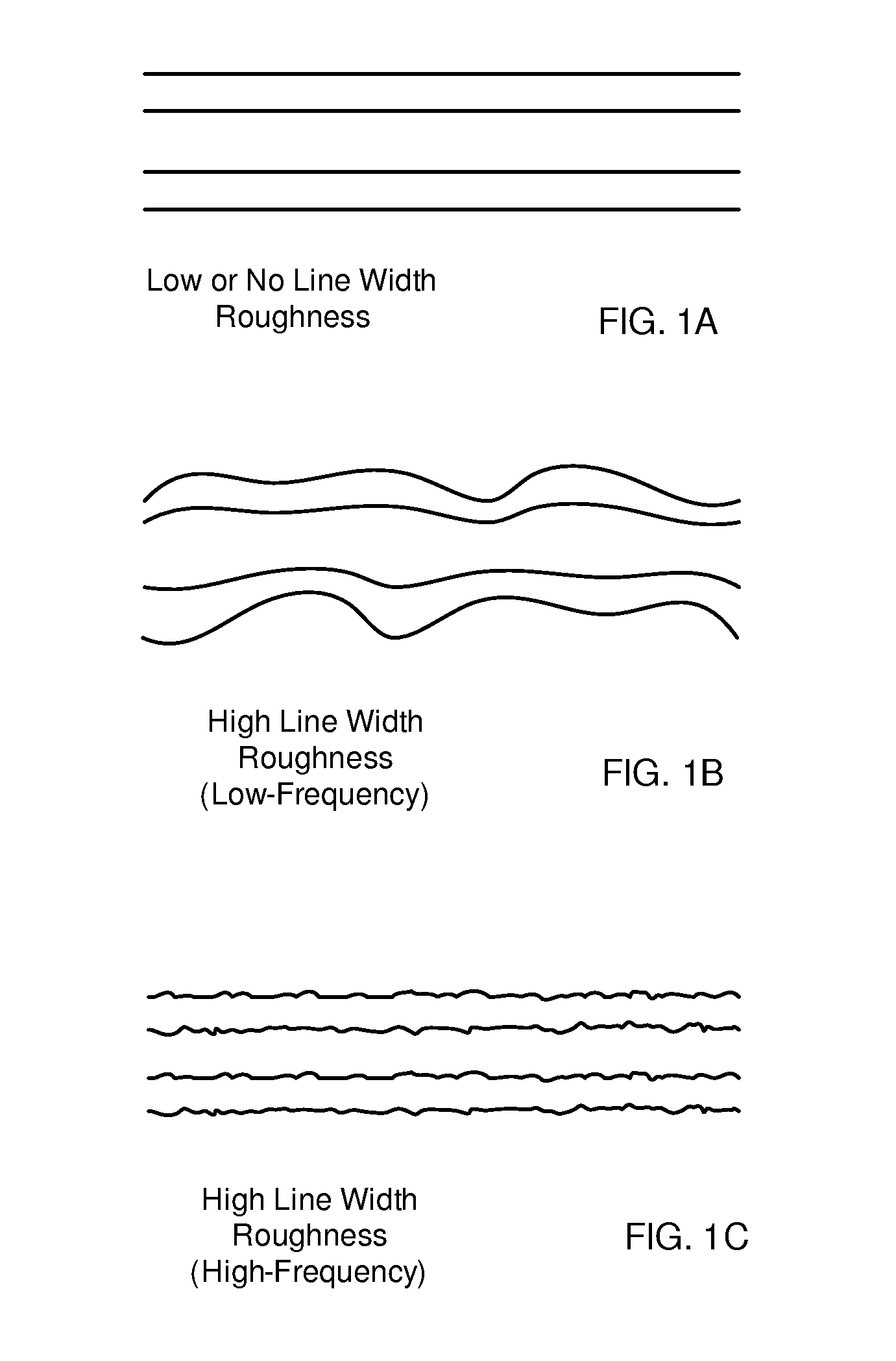

Method for reducing photoresist figure linewidth roughness

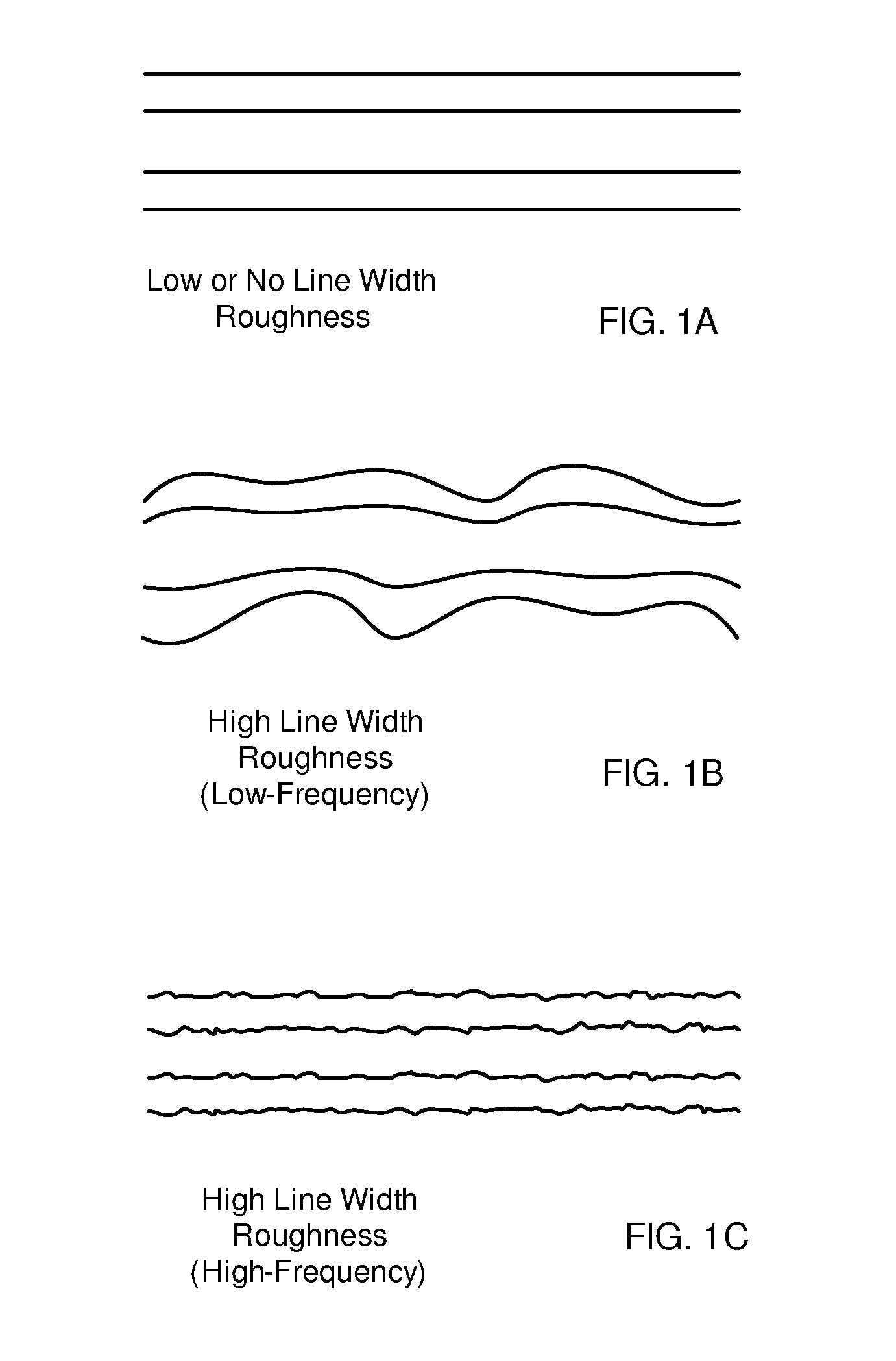

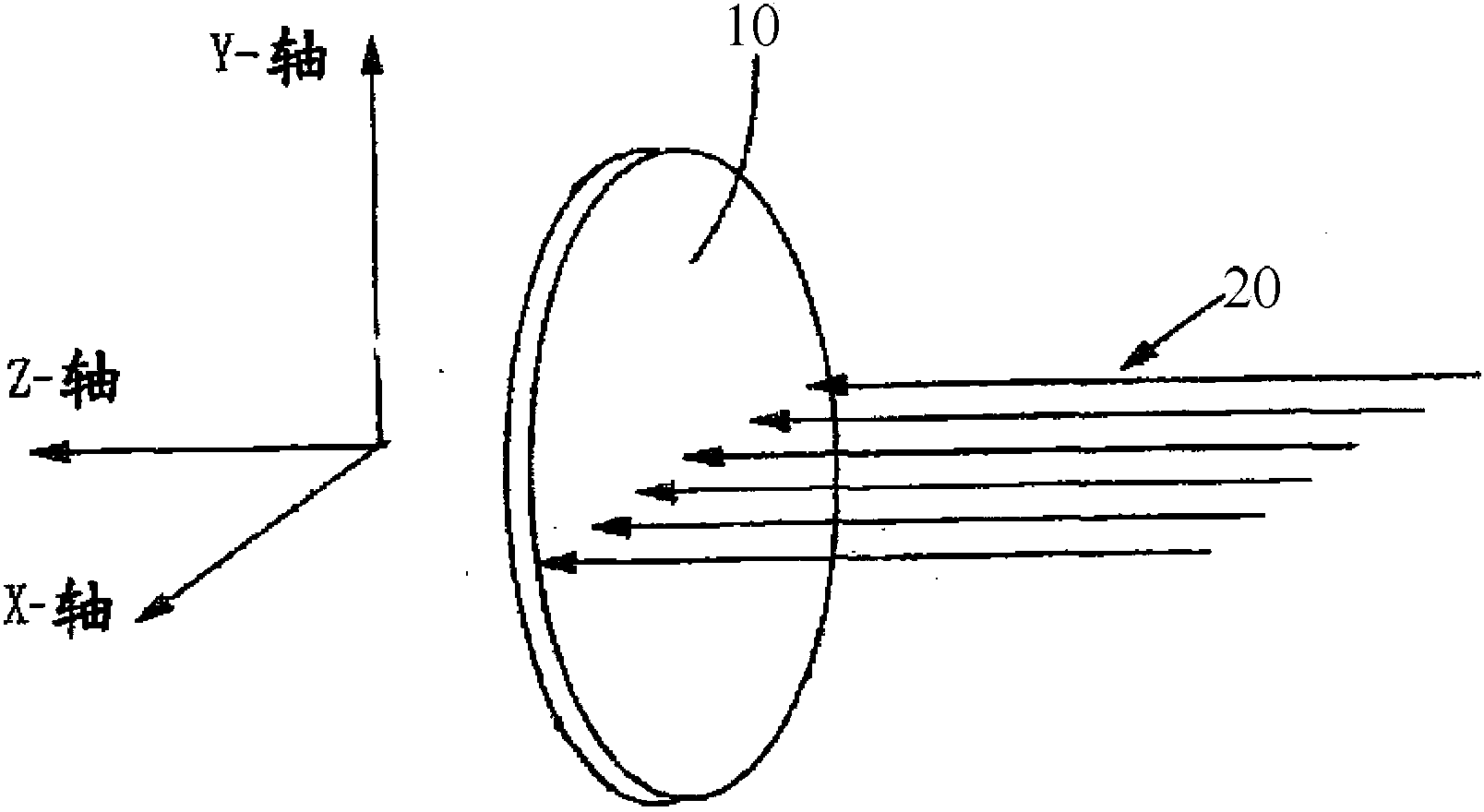

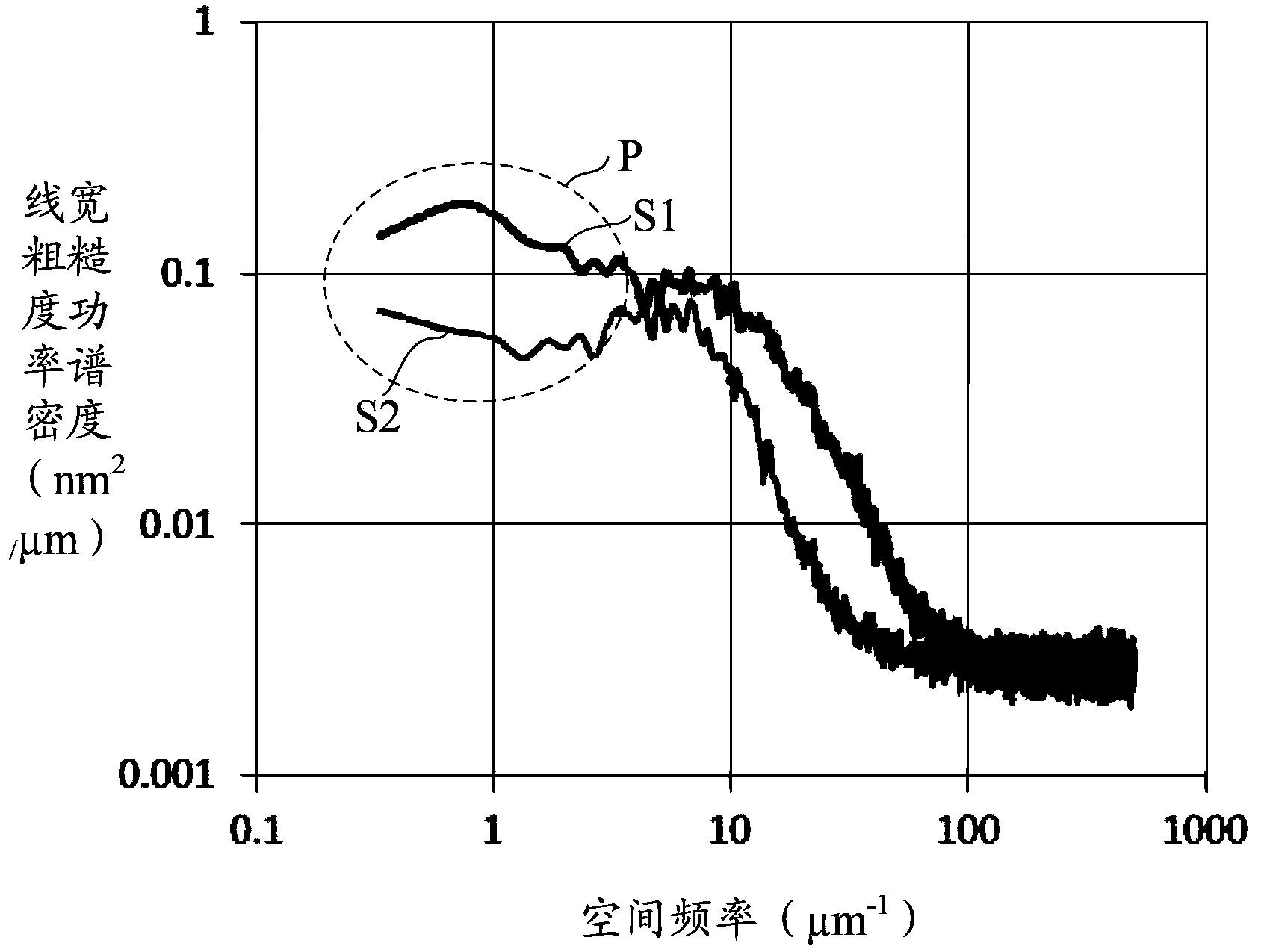

InactiveCN104345568AHigh frequency line width roughness reductionReduced linewidth roughness at low frequenciesSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusBand shapeIon beam

A provided method for reducing photoresist figure linewidth roughness comprises putting a substrate with a photoresist figure on the surface in a vacuum chamber; and using a band-shaped ion beam to perform ion injection on the photoresist figure, so as to reduce the low-frequency linewidth roughness of the photoresist figure. After ion injection, the low-frequency linewidth roughness of the photoresist figure is substantially reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Sulfonium sulfonate salt photoacid generator synthesized from guaiacol and synthesis method for sulfonium sulfonate salt photoacid generator

PendingCN111138406AReduce spreadHigh molecular weightSulfonic acids salts preparationPhotosensitive materials for photomechanical apparatusChemical synthesisSilanes

The invention discloses a sulfonium sulfonate salt photoacid generator synthesized from guaiacol and a synthesis method for the sulfonium sulfonate salt photoacid generator, belonging to the fields ofchemical synthesis and photoetching materials. The photoacid generator has a structural general formula which is described in the specification. In the structural general formula, R1 is one selectedfrom the group consisting of groups which are described in the specification; and R2 is one selected from the group consisting of a covalent bond, an alkyl group, a cycloalkyl group, an ester group containing alkyl group and a fluorine-containing alkyl group. The synthesis method for the photoacid generator comprises the following steps: allowing the guaiacol to react with a sulfonate compound soas to obtain an intermediate; and allowing the intermediate to react with (cyclohexyl-1,5-dienyloxy)-trimethyl-silane, tetramethylene sulfoxide and trifluoroacetic anhydride so as to obtain the sulfonium sulfonate salt photoacid generator is obtained. According to the invention, a raw material, namely the guaiacol adopted in the method provided by the invention has large molecular weight, so the photoacid generator formed by the guaiacol also has large molecular weight; diffusion of the photoacid generator can be reduced; and improvement of the edge roughness, reduction of the line width roughness and improvement of the resolution ratio are facilitated.

Owner:上海博栋化学科技有限公司

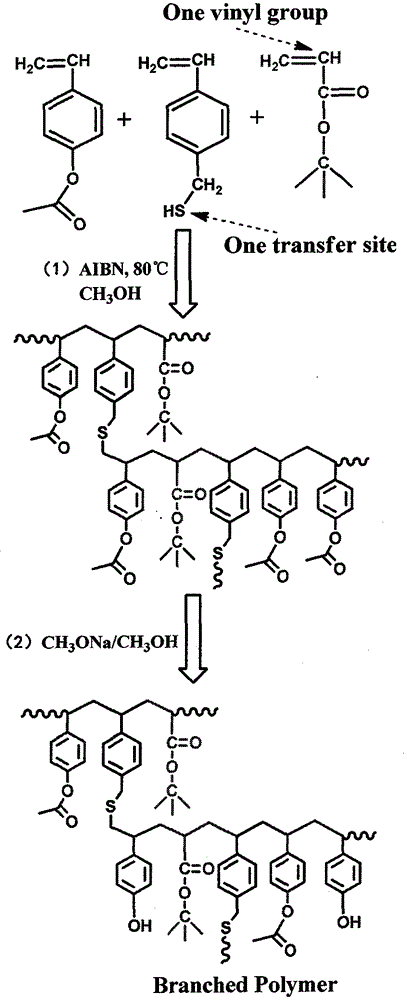

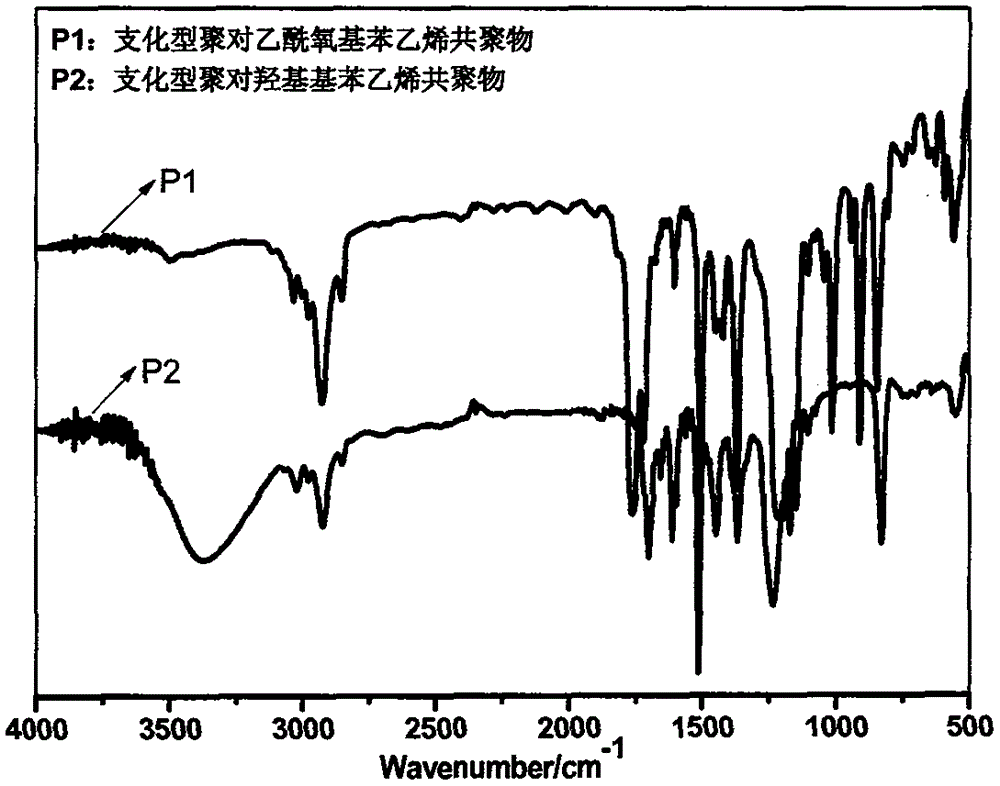

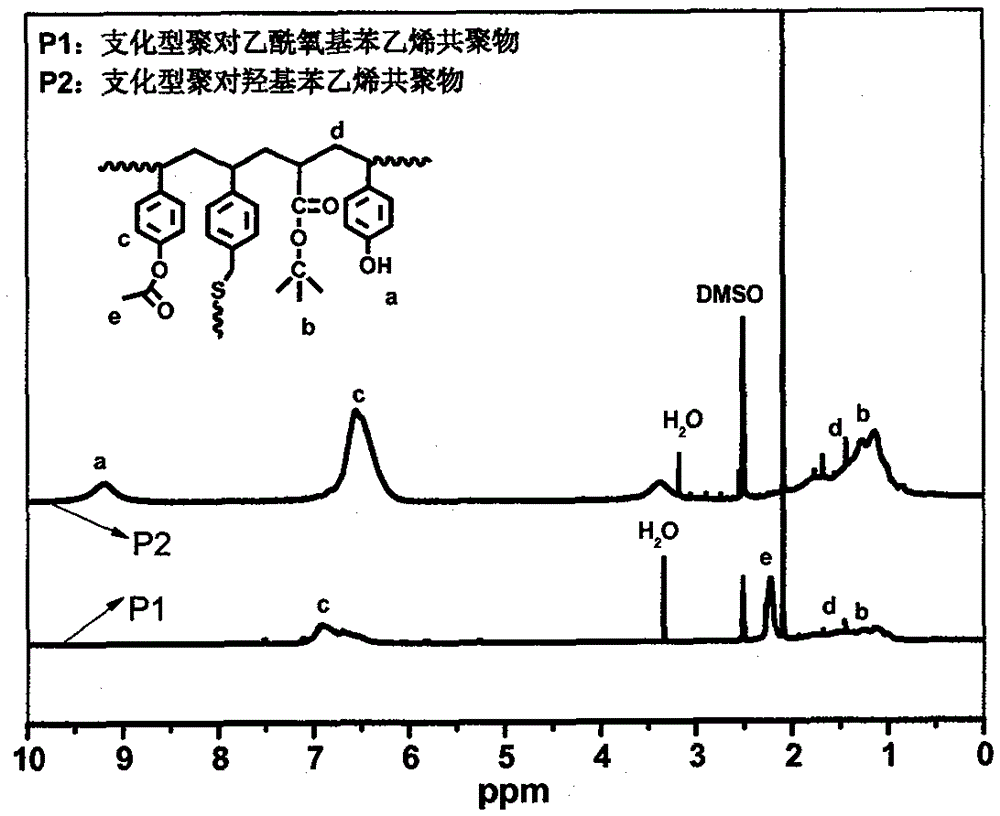

Branched poly (p-hydroxystyrene) copolymer used for 248nm photoresist

InactiveCN105254791AReduce usageReduce pollutionPhotosensitive materials for photomechanical apparatusHeat resistanceImage resolution

The invention discloses a branched poly (p-hydroxystyrene) copolymer used for 248nm photoresist, and a preparation method thereof. The preparation method comprises following steps: simple free radical polymerization is adopted, 4-acetoxystyrene and tert-butyl acrylate are taken as polymerization monomers, 4-vinyl benzyl mercaptane is taken as a chain transfer monomer, a branched poly (p-acetoxy styrene) copolymer is prepared via precipitation polymerization in absolute methanol; and the branched poly (p-hydroxystyrene) copolymer with protecting groups is obtained via partial deacetylation oxidation of the branched poly (p-acetoxy styrene) copolymer. The raw materials are widely available and cheap; operation of the polymerization process is simple; reactions are easy to control; polymer molecular weight can be controlled via adjusting reaction time and the content of the chain transfer monomer; the branched poly (p-hydroxystyrene) copolymer is high in photopermeability, excellent in heat resistance and etching resistance, and weak in inter molecule chain entanglement, so that it is possible to improve distinguishability performance of 248nm photoresist.

Owner:SUZHOU RUIHONG ELECTRONIC CHEM CO LTD +1

Line width roughness improvement with noble gas plasma

ActiveUS8753804B2Reduce line width roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistNoble gas

A method for forming a photoresist mask may comprise providing a ultra-violet (UV) producing gas to a vacuum chamber having a substrate, ionizing the UV producing gas to produce UV rays to irradiate the substrate, and etching features into the substrate through the photoresist mask.

Owner:LAM RES CORP

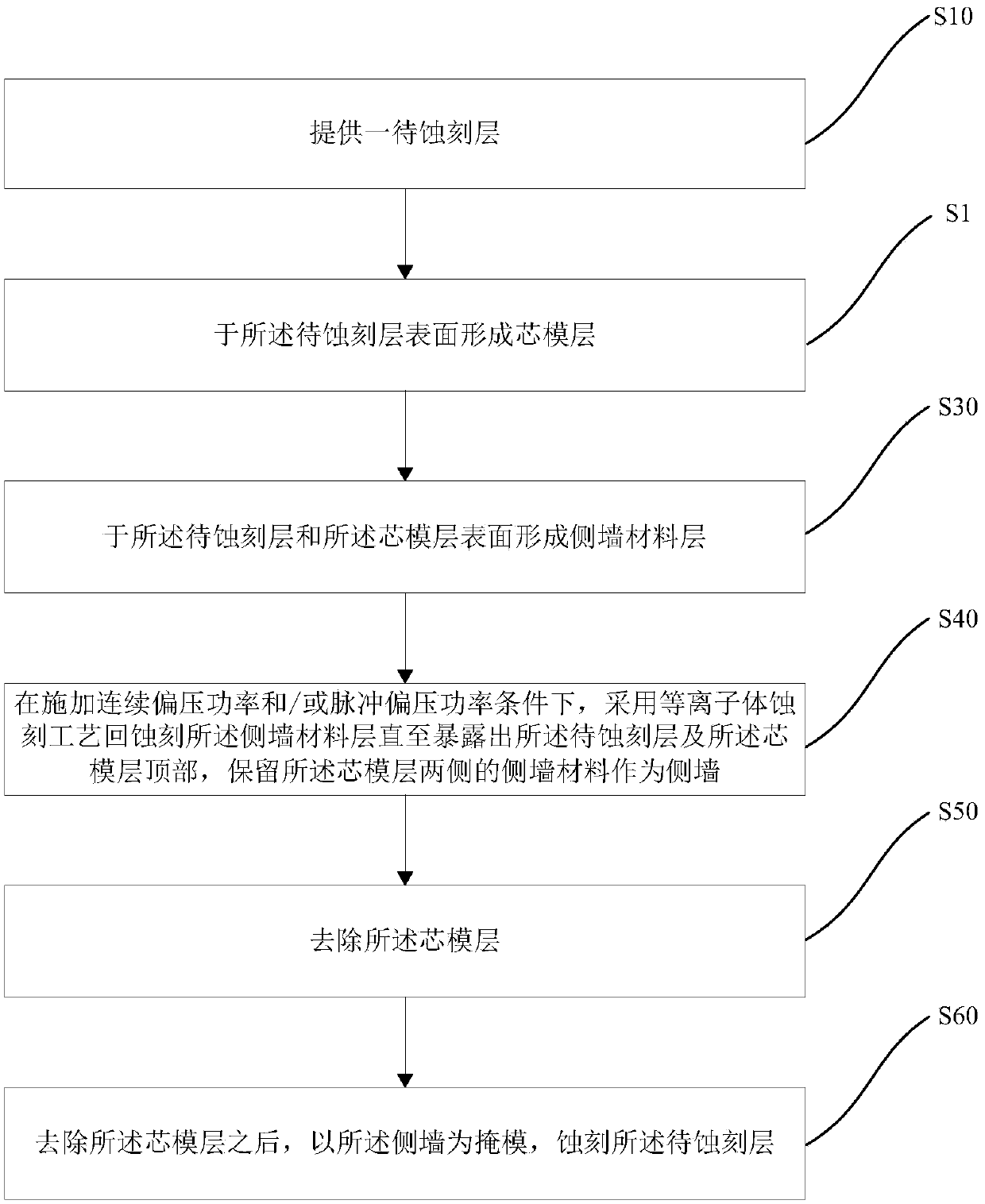

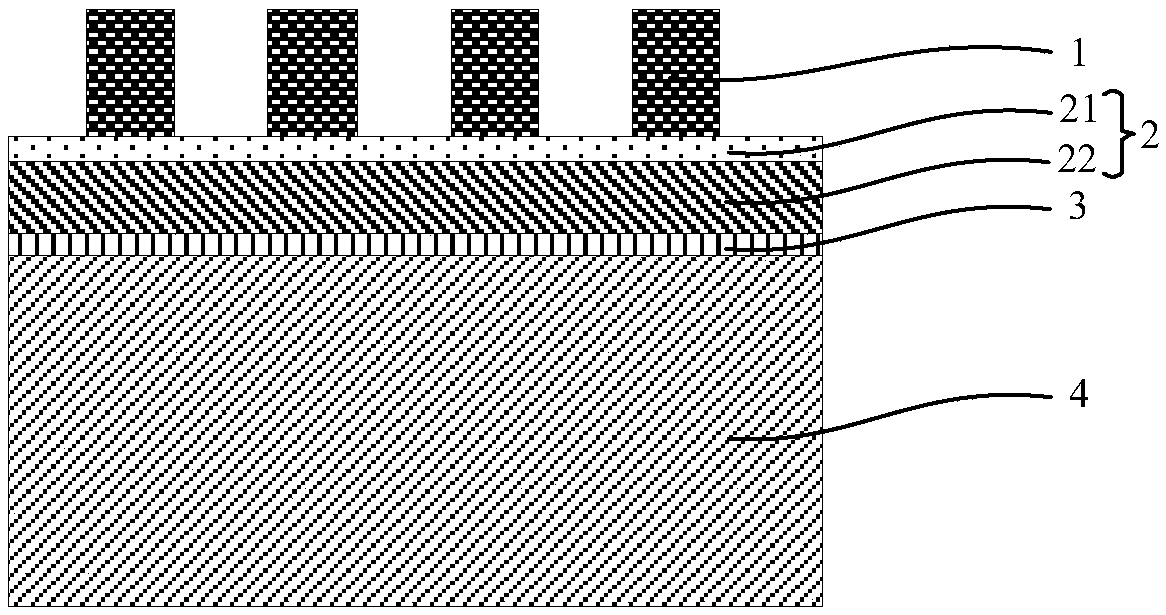

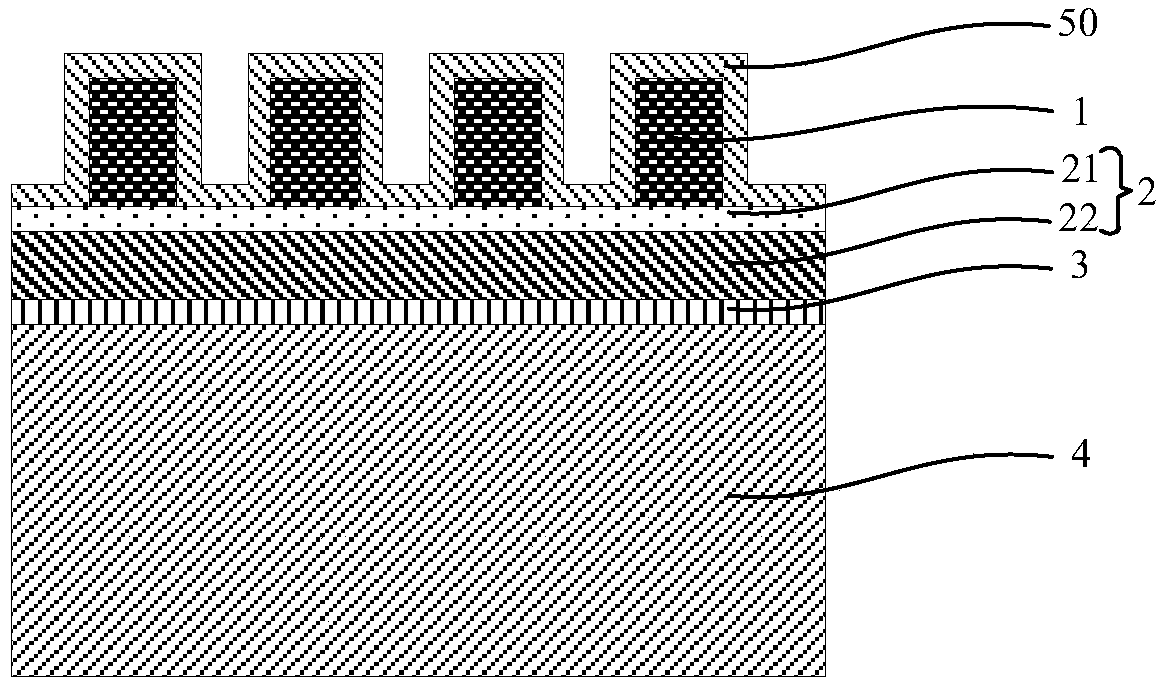

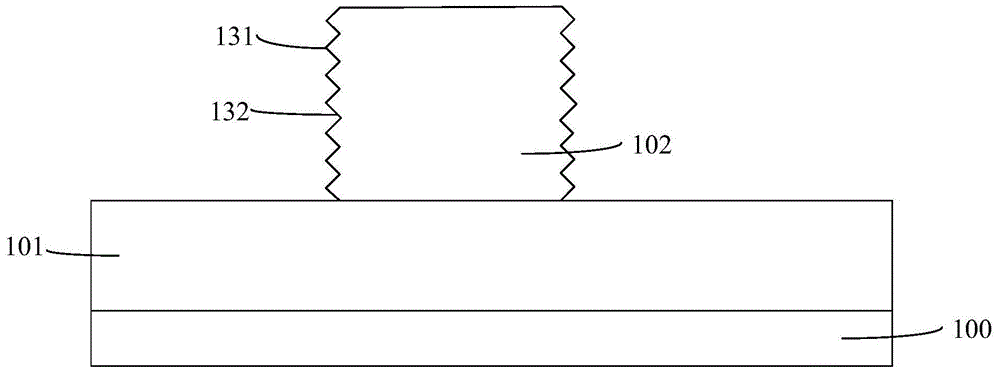

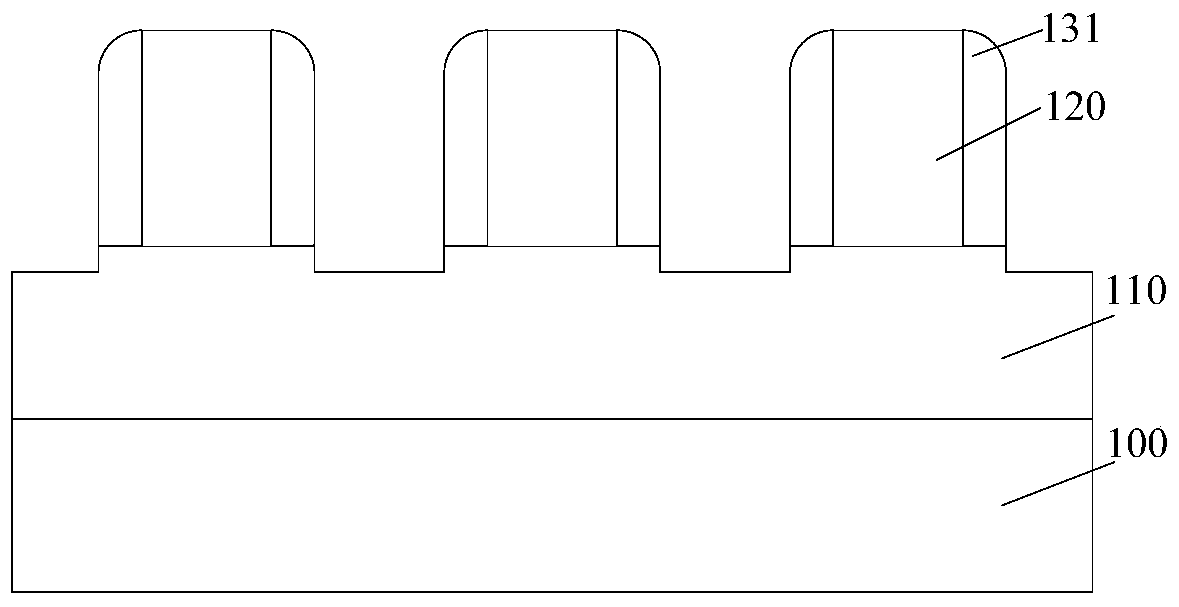

Preparation method of semiconductor structure

PendingCN110957210AReduce line width roughnessIncreased etch resistanceSemiconductor/solid-state device manufacturingSemiconductor structurePlasma etching

The invention provides a preparation method of a semiconductor structure. The preparation method comprises the following steps: providing a to-be-etched layer; forming a core mold layer on the surfaceof the to-be-etched layer; forming a side wall material layer on the surfaces of the to-be-etched layer and the core mold layer; under the condition of applying continuous bias power and / or pulse bias power, etching back the side wall material layer by adopting a plasma etching process until the to-be-etched layer and the top of the core mold layer are exposed, and reserving the side wall materials on the two sides of the core mold layer as side walls; removing the core mold layer; and after the core mold layer is removed, etching the to-be-etched layer by taking the side walls as masks. By utilizing the method, the line width roughness of the semiconductor structure is sequentially controlled and reduced through different steps, and the pattern feature structure is accurately transferredto the substrate, so that the performance of the device is improved.

Owner:CHANGXIN MEMORY TECH INC

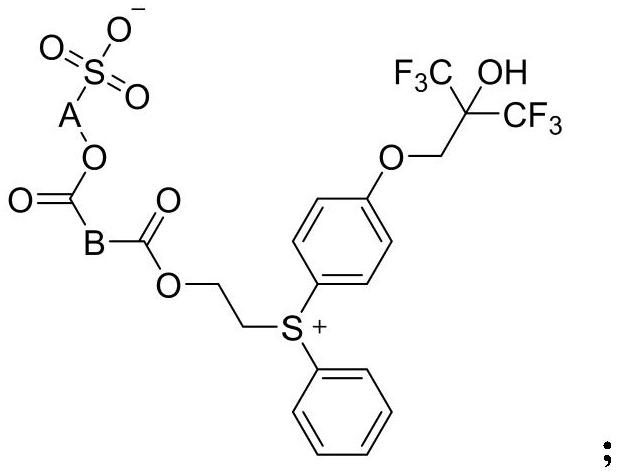

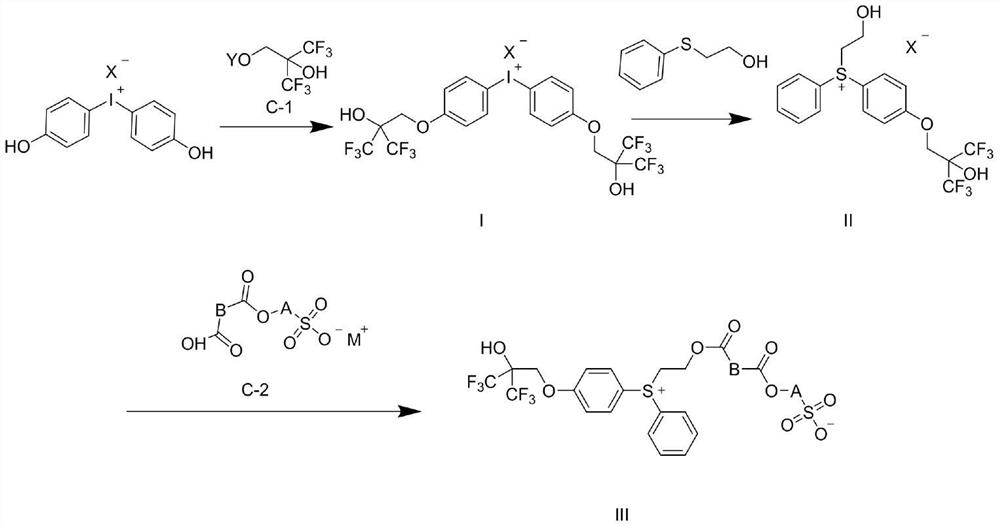

Photoinduced acid generator with diphenyl sulfonium structure and synthesis method of photoinduced acid generator

PendingCN112920099AReduce line width roughnessLarge molecular sizeOrganic chemistryPhotosensitive materials for photomechanical apparatusAlkaneLight source

The invention discloses a photoacid generator with a diphenyl sulfonium structure and a synthesis method of the photoacid generator, and relates to the field of photoresists, the photoacid generator has the following structure shown in the description, wherein A is C1-C5 fluoroalkane, and B is a naphthenic base of C3-C10. The photoacid generator disclosed by the invention can control acid diffusion, reduce line width roughness, prevent pattern damage and form photoetching patterns with uniform sizes, and has high transparency under a 193nm light source.

Owner:华衍化学(上海)有限公司

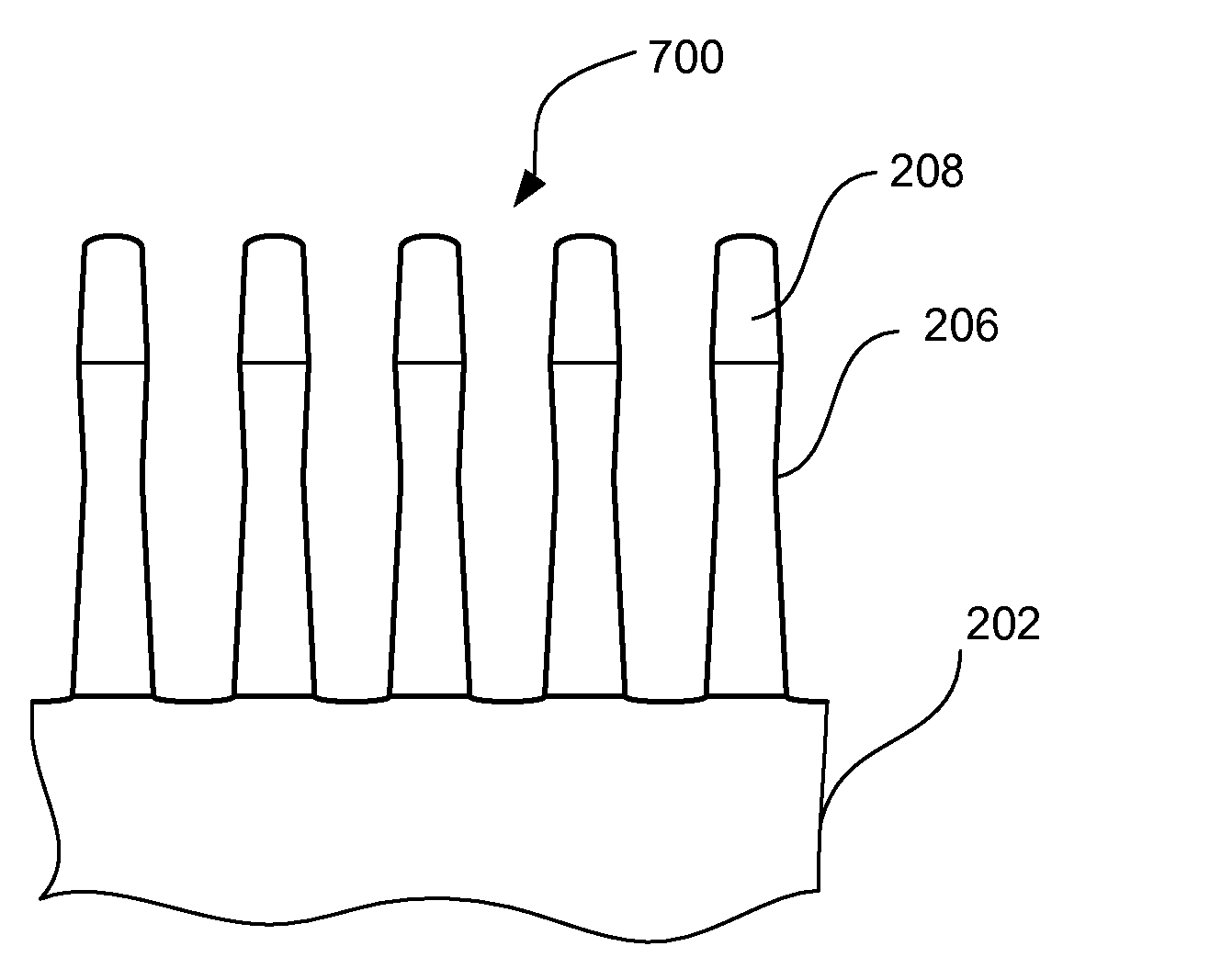

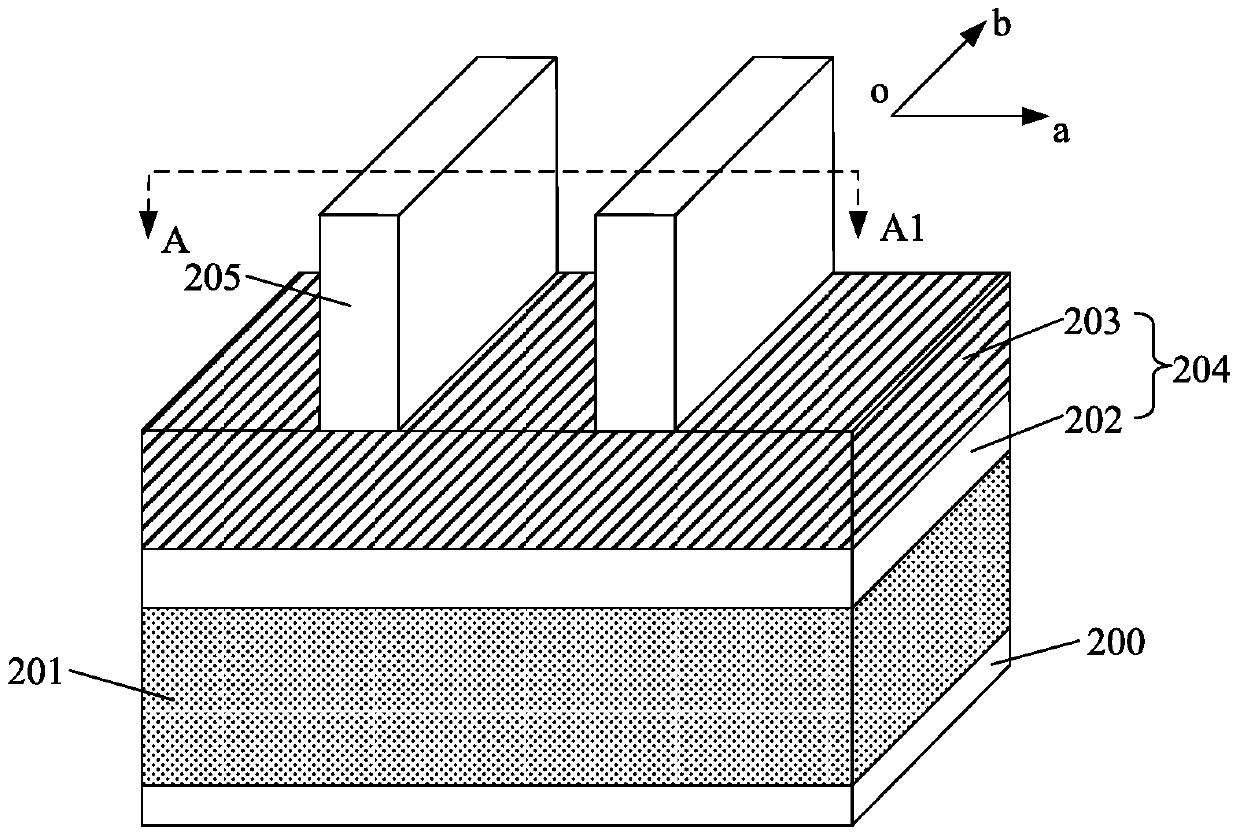

Forming method of fin type field-effect transistor

ActiveCN106298929AImprove electrical performanceReduce line width roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorMaterials science

A forming method of a fin type field-effect transistor comprises the steps of forming a silicon material layer on a film surface of a gate; forming a plurality of discrete first pattern layers on the silicon material layer, wherein the first pattern layers stretches across at least one fin part, and the arrangement direction of the first pattern layers is parallel to the extending direction of the fin part; taking the first pattern layers as a mask, and etching the silicon material layer until the film surface of the gate is exposed, and forming a plurality of discrete initial silicon layers on the film surface of the gate, wherein the initial silicon layers and a surface of a side wall perpendicular to the extending direction of the fin part have first line width roughness; and performing repairing etching treatment on the initial silicon layers and the side wall perpendicular to the extending direction of the fin part so that the initial silicon layers and the surface of the side wall perpendicular to the extending direction of the fin part have second line width roughness, wherein the second line width roughness is smaller than the first line width roughness. By the forming method, the quality of the formed gate is improved, the line width roughness of the gate and the side wall perpendicular to the extending direction of the fin part is improved, and thus, the electrochemical performance of the fin type field-effect transistor is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

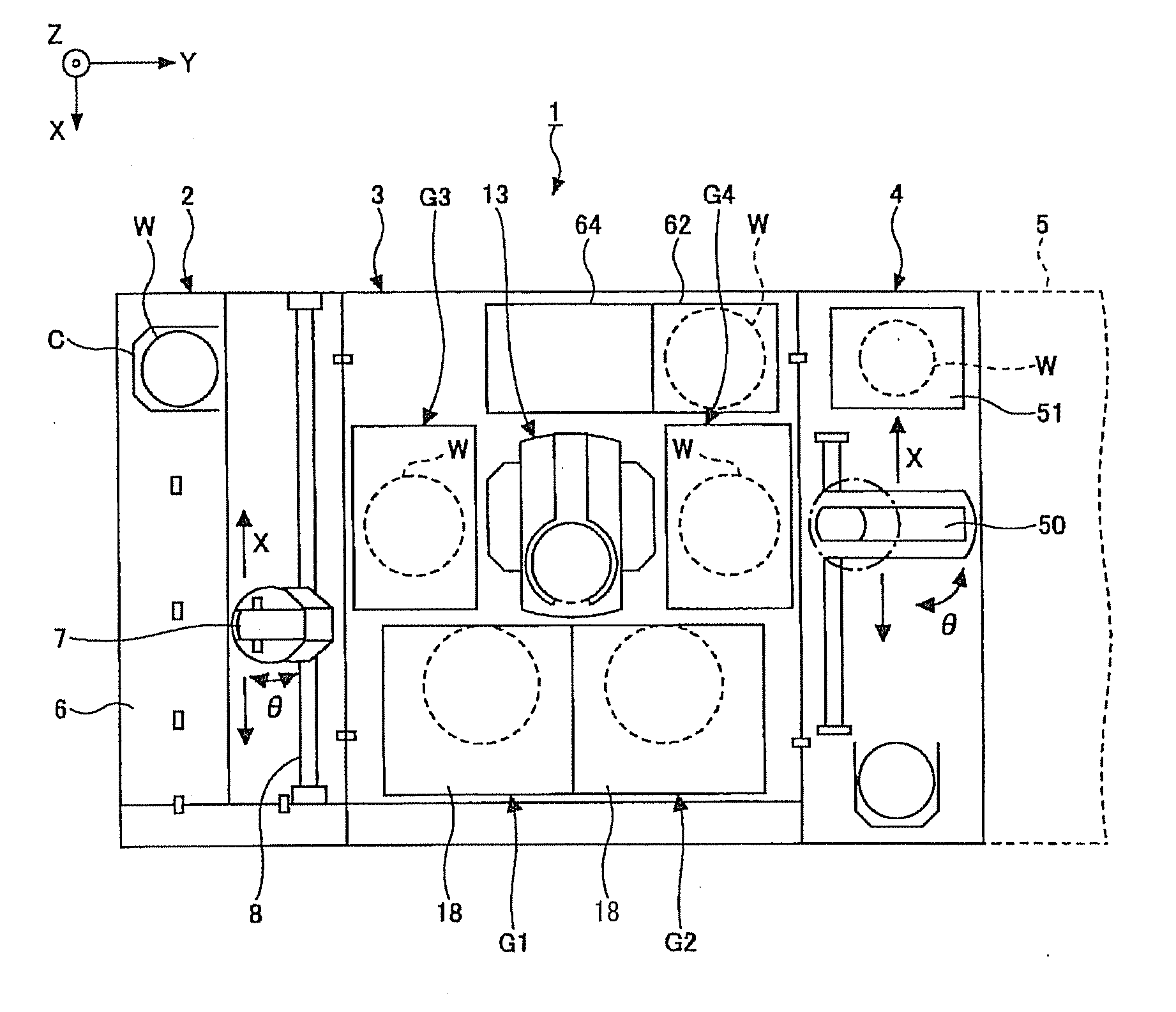

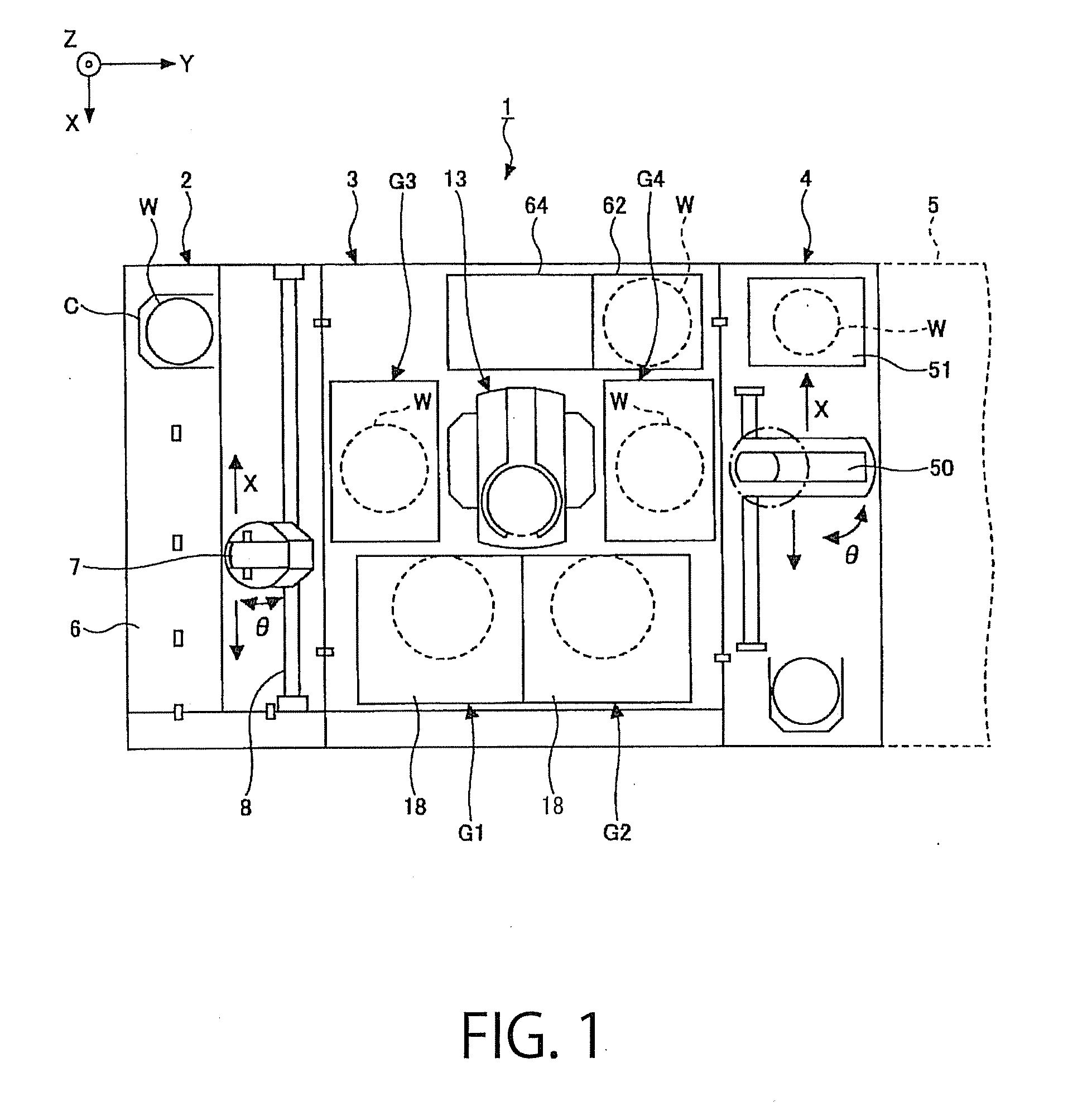

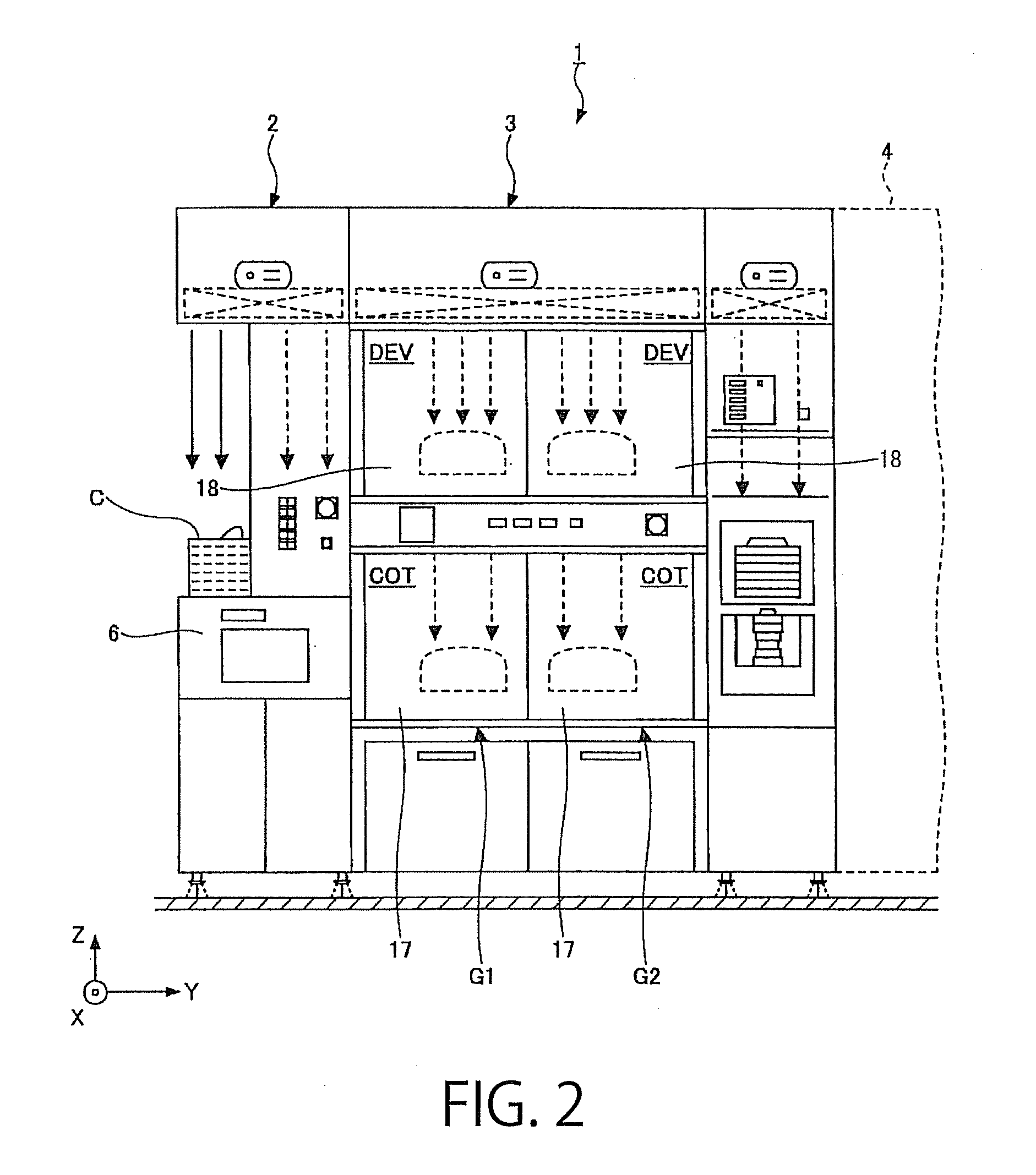

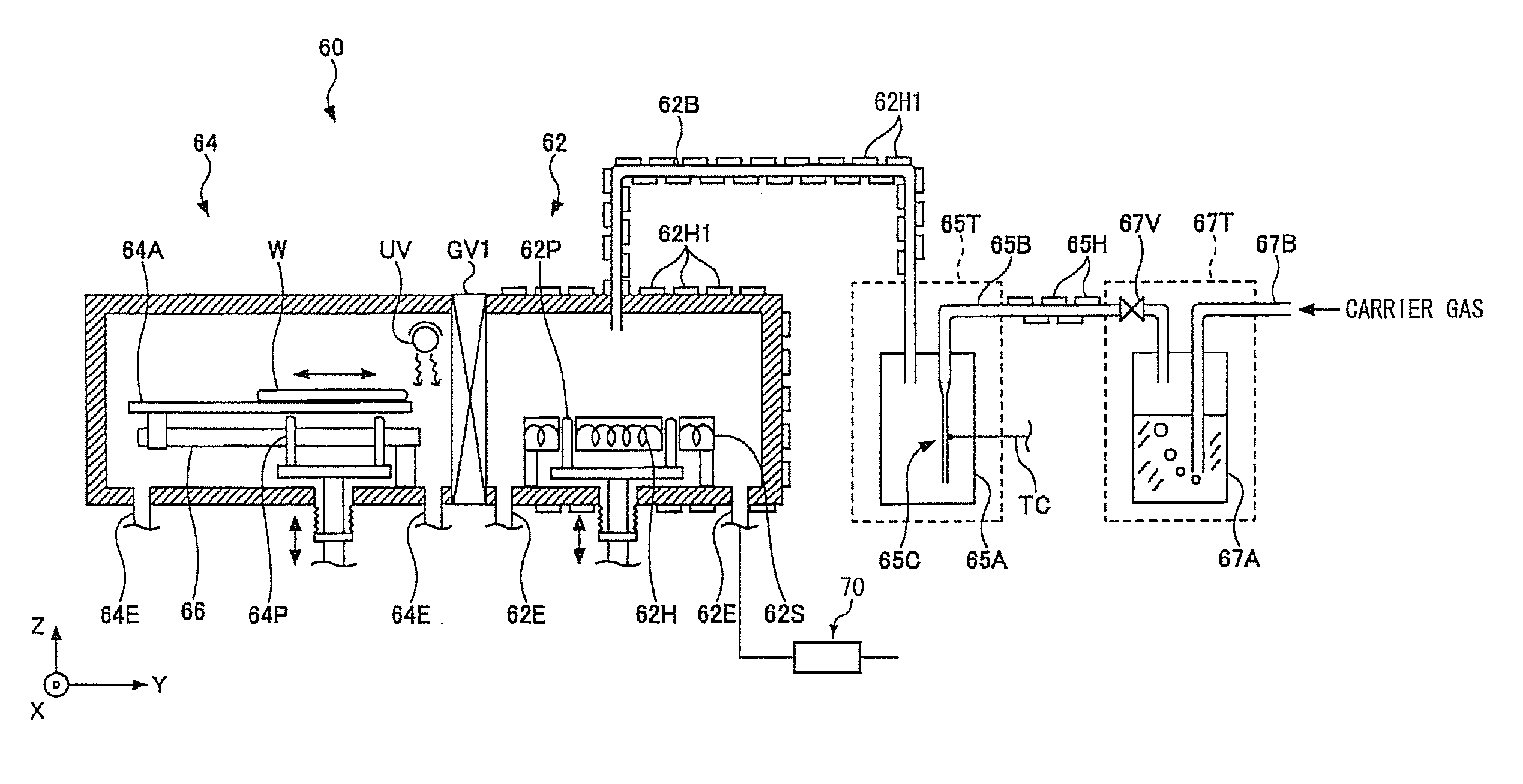

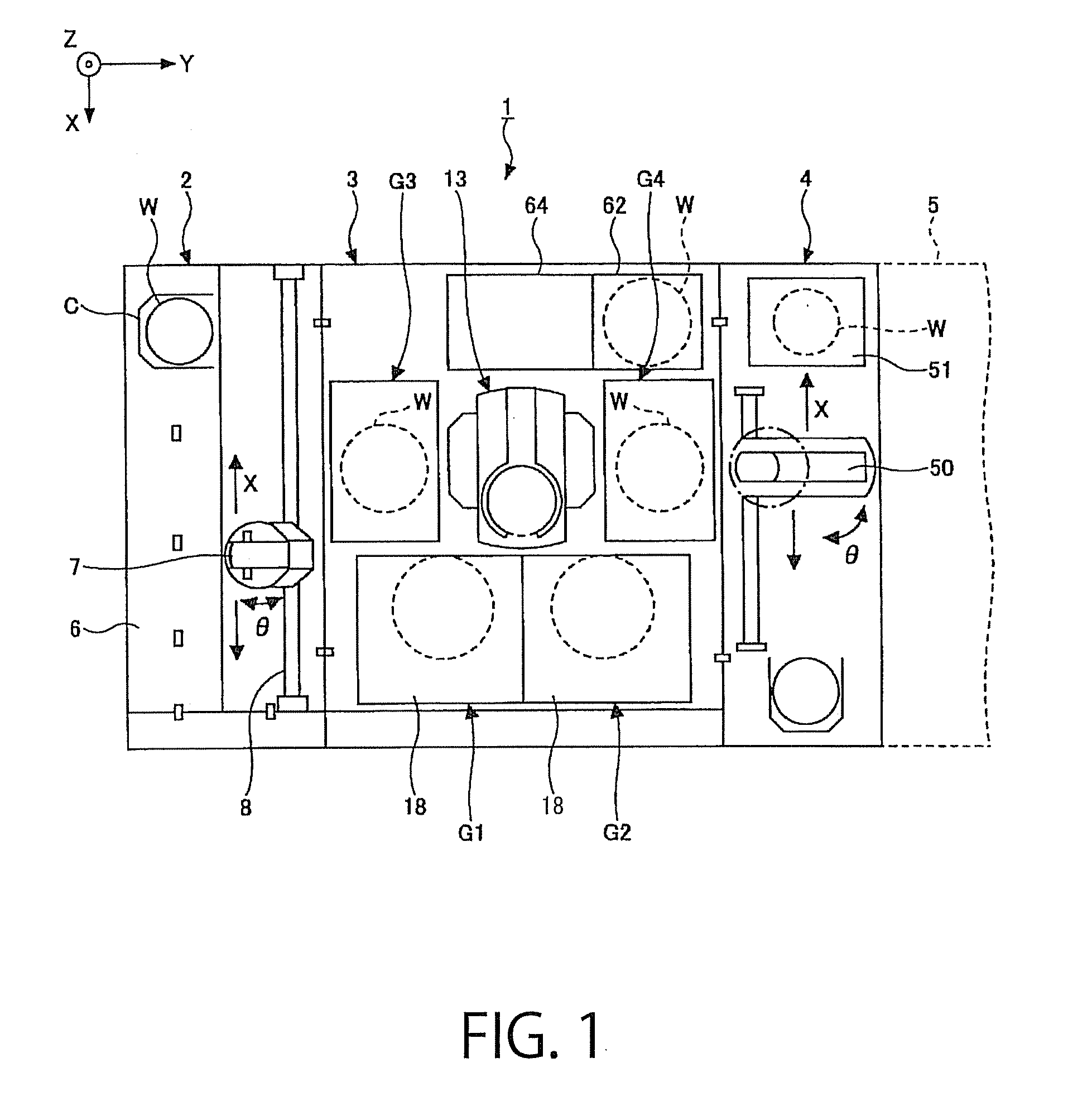

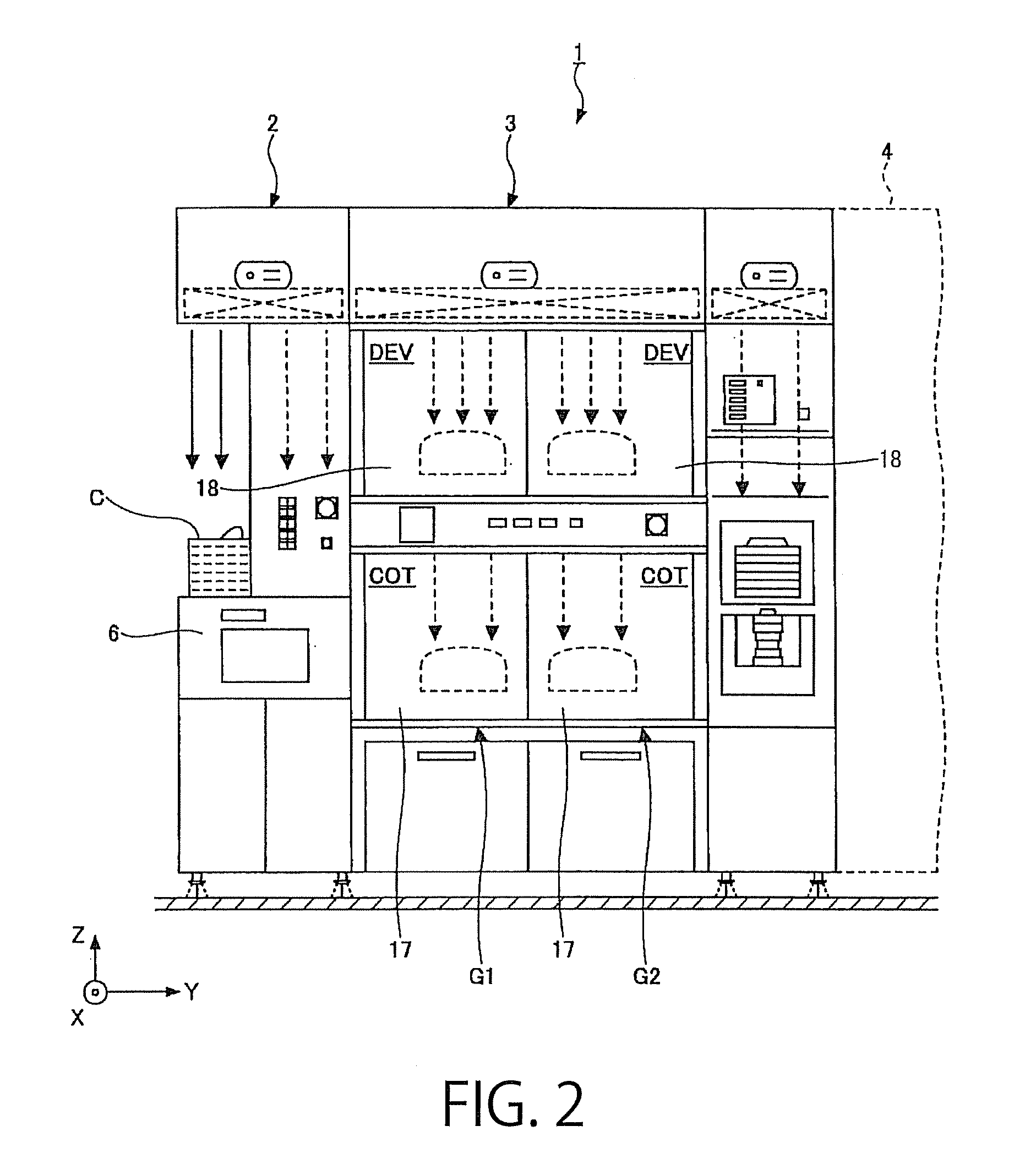

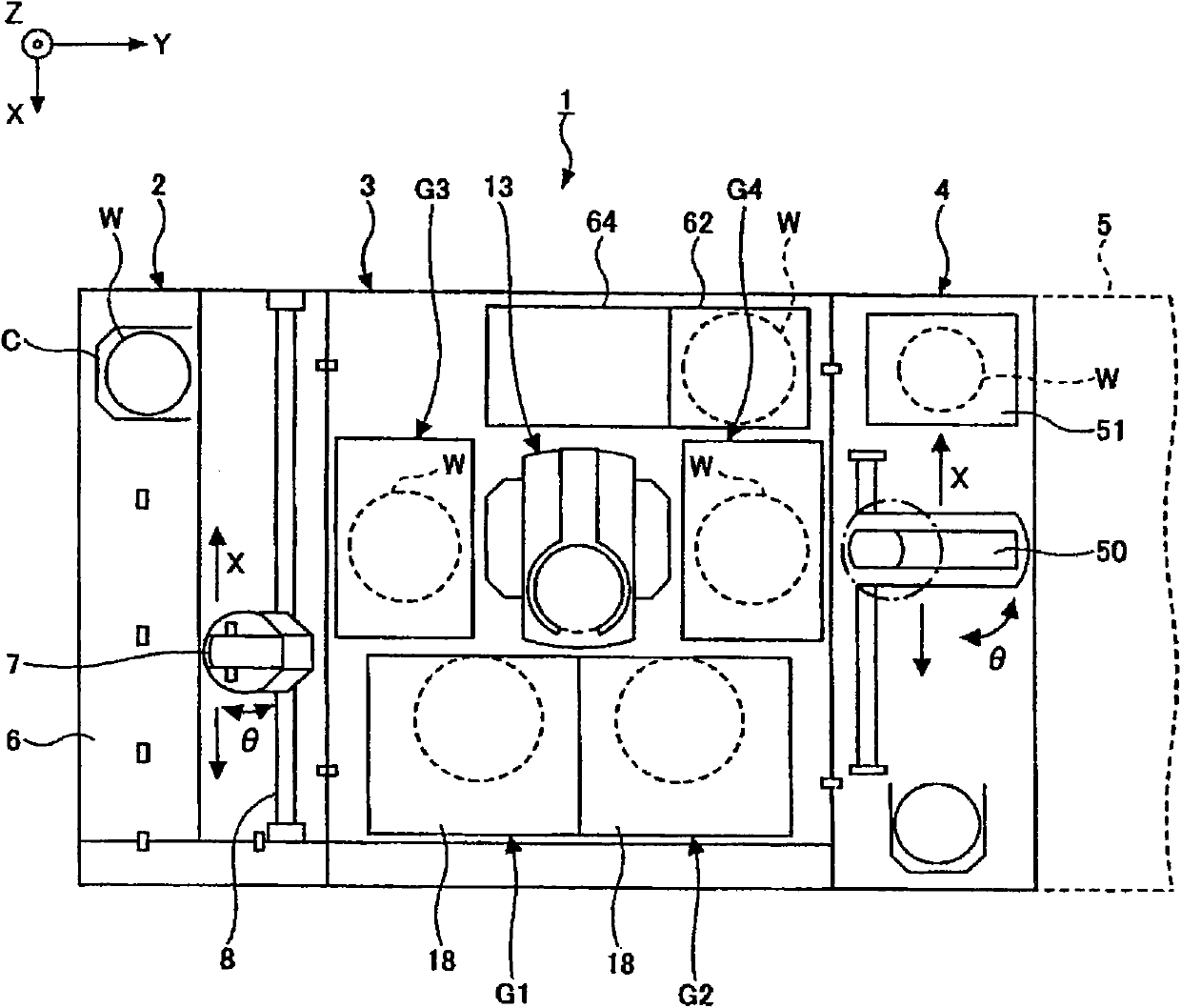

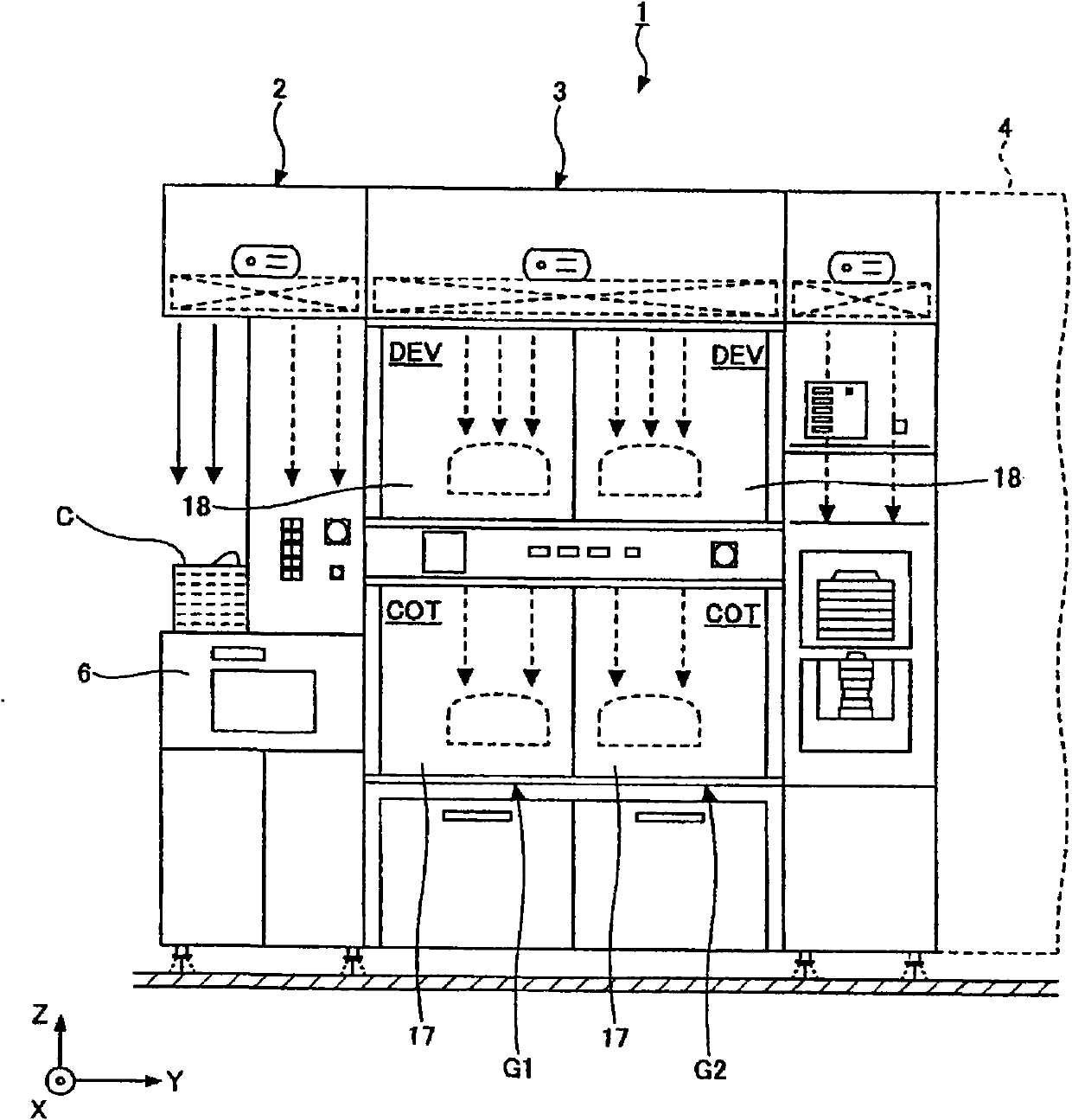

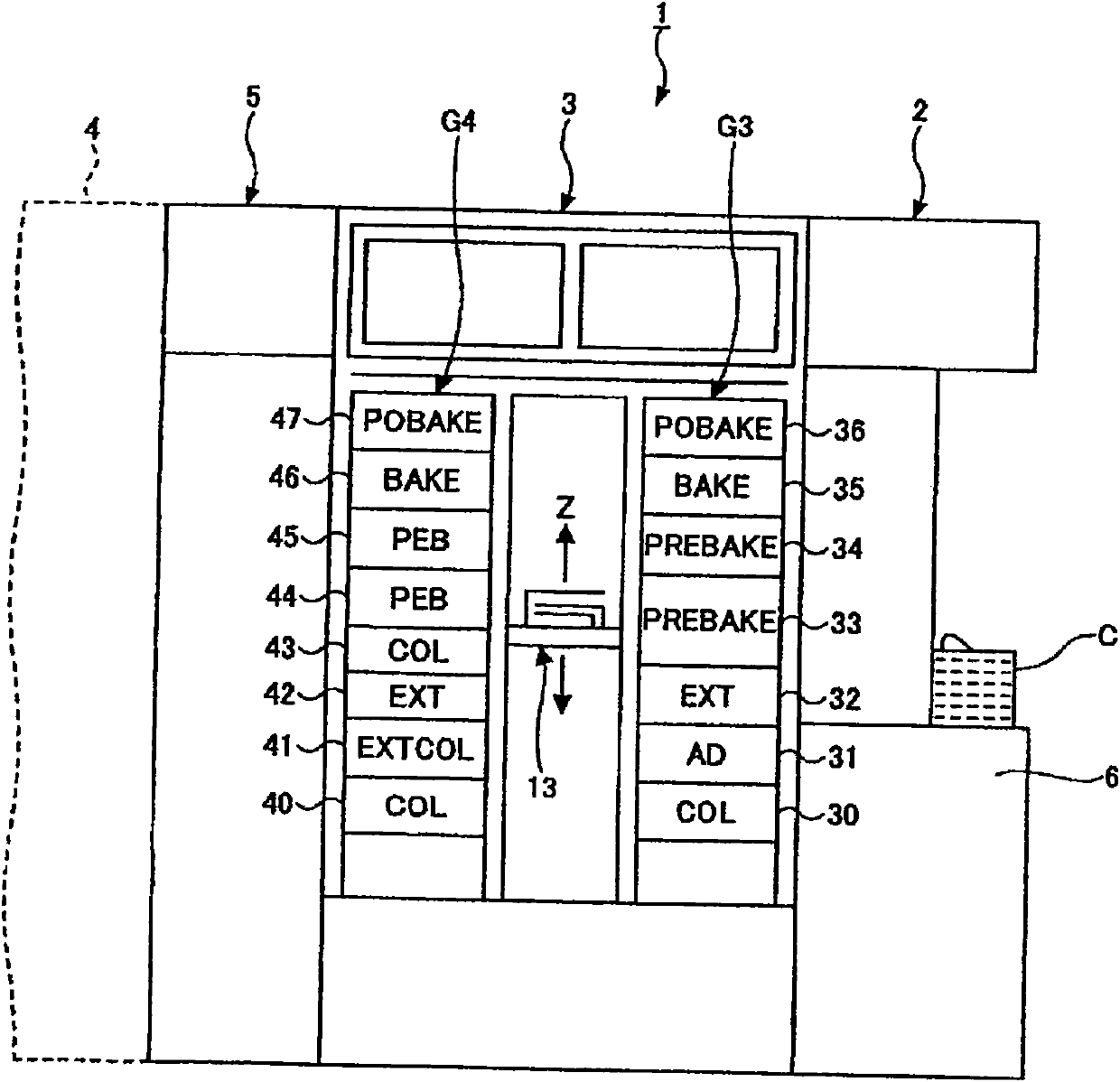

Resist coating and developing apparatus and method

ActiveUS20110065052A1Reduce line width roughnessPreventing a solvent gas from diffusing outsideLiquid surface applicatorsSpraying apparatusResistPhysical chemistry

A resist coating / developing apparatus includes: a resist film-forming unit configured to apply a resist onto a substrate to form thereon a resist film; a resist developing unit configured to develop the resist film after exposure to pattern the resist film; a solvent gas generator configured to generate a solvent gas containing a vapor of a solvent having a property of dissolving the resist film; a solvent gas conditioner connected to the solvent gas generator and configured to condition the solvent gas generated in the solvent gas generator; a processing chamber configured to house the substrate having thereon the resist film which has been developed and patterned in the resist developing unit, and connected to the solvent gas conditioner so that the solvent gas, which has been conditioned in the solvent gas conditioning section, is supplied to the substrate housed in the processing chamber; and an exhaust system connected to the processing chamber to evacuate the processing chamber to a reduced pressure.

Owner:TOKYO ELECTRON LTD

Resist coating and developing apparatus and method

ActiveUS8411246B2Reduce line width roughnessPreventing a solvent gas from diffusing outsideLiquid surface applicatorsSpraying apparatusResistPhysical chemistry

A resist coating / developing apparatus includes: a resist film-forming unit configured to apply a resist onto a substrate to form thereon a resist film; a resist developing unit configured to develop the resist film after exposure to pattern the resist film; a solvent gas generator configured to generate a solvent gas containing a vapor of a solvent having a property of dissolving the resist film; a solvent gas conditioner connected to the solvent gas generator and configured to condition the solvent gas generated in the solvent gas generator; a processing chamber configured to house the substrate having thereon the resist film which has been developed and patterned in the resist developing unit, and connected to the solvent gas conditioner so that the solvent gas, which has been conditioned in the solvent gas conditioning section, is supplied to the substrate housed in the processing chamber; and an exhaust system connected to the processing chamber to evacuate the processing chamber to a reduced pressure.

Owner:TOKYO ELECTRON LTD

Method of forming semiconductor device

ActiveCN106328498BReduce etch damageReduce line width roughnessSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

The invention provides a forming method of a semiconductor device. The method comprises the steps as follows: a to-be-etched material layer is provided; a first mask material layer is formed on the surface of the to-be-etched material layer; the first mask material layer is etched by using a focused ion beam etching process; a plurality of discrete first mask layers are formed on the surface of the to-be-etched material layer; a second mask layer is formed on the surface of the to-be-etched material layer among the discrete first mask layers; the top surface of the second mask layer is flush with those of the first mask layers; the first mask layers are removed and the second mask layer is reserved; transverse etch-back is carried out on the second mask layer to form a third mask layer; and the to-be-etched material layer is etched by taking the third mask layer as a mask to form a target pattern. According to the forming method of the semiconductor device, the performance of the target pattern in the semiconductor device is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

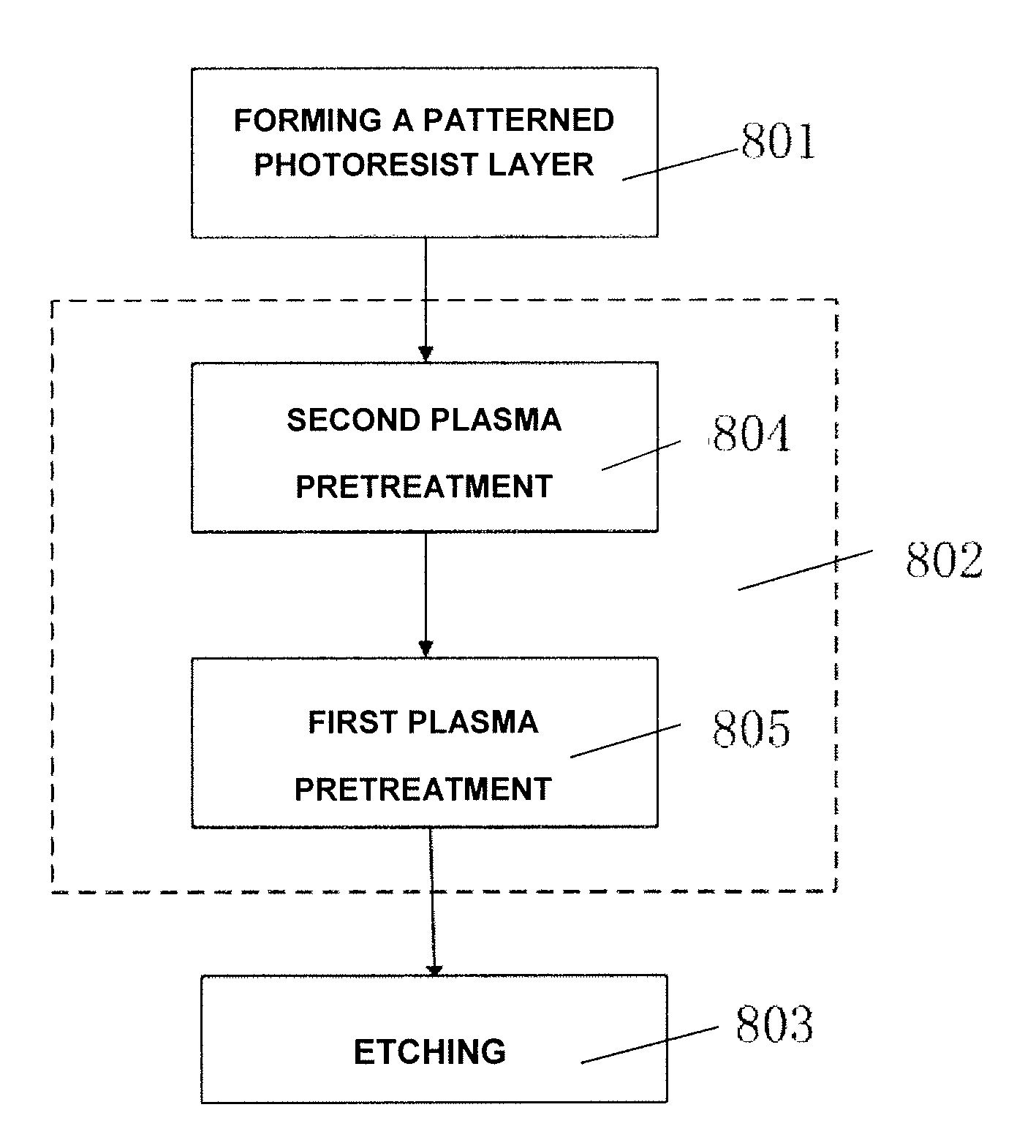

Method of fabricating a semiconductor device

ActiveUS8664122B2Reduce line width roughnessImprove line width roughnessSemiconductor/solid-state device manufacturingPhotosensitive material processingResistLine width

The present invention discloses a method of fabricating a semiconductor device. In the present invention, after the formation of a photo-resist mask on a substrate, the photo-resist is subjected to a plasma pre-treatment, and then etch is conducted. With the plasma pre-treatment, a line width roughness of a linear pattern of the photo-resist can be improved, and thus much better linear patterns can be formed on the substrate during the subsequent etching steps.

Owner:SEMICON MFG INT (BEIJING) CORP

Resist coating and developing apparatus and method

ActiveCN102023498AAvoid pollutionReduce line width roughnessSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusEngineeringSolvent

A resist coating / developing apparatus (1) includes: a resist film-forming unit configured to apply a resist onto a substrate (W) to form thereon a resist film; a resist developing unit (18) configured to develop the resist film after exposure to pattern the resist film; a solvent gas generator configured to generate a solvent gas containing a vapor of a solvent having a property of dissolving theresist film; a solvent gas conditioner connected to the solvent gas generator and configured to condition the solvent gas generated in the solvent gas generator; a processing chamber (62) configured to house the substrate having thereon the resist film which has been developed and patterned in the resist developing unit (18), and connected to the solvent gas conditioner so that the solvent gas, which has been conditioned in the solvent gas conditioning section, is supplied to the substrate (W) housed in the processing chamber (62); and an exhaust system connected to the processing chamber to evacuate the processing chamber to a reduced pressure.

Owner:TOKYO ELECTRON LTD

Sulfonium sulfonate photoacid generator synthesized from abietic acid and synthesis method of sulfonium sulfonate photoacid generator

InactiveCN112645849AGood etch resistanceExcellent solubilityOrganic compound preparationOrganic chemistry methodsImage resolutionLight source

The invention discloses a sulfonium sulfonate photoacid generator synthesized from abietic acid, and relates to the field of photoacid generators. The sulfonium sulfonate photoacid generator has a structural formula shown in the specification, in the formula, R1 is an oxygen-containing linking group, and R2 is a fluoroalkyl group. The photoacid generator can reduce the diffusion of the photoacid generator, improve the edge roughness, reduce the line width roughness and improve the resolution; the photoacid generator is more transparent under 193 nm, and exposure under a 193 nm light source is facilitated; the etching resistance is excellent; the photoacid generator is balanced in hydrophilicity and lipophilicity, has proper adhesive force and excellent solubility, is more uniform in dissolution, and is simple in synthetic route.

Owner:上海博栋化学科技有限公司

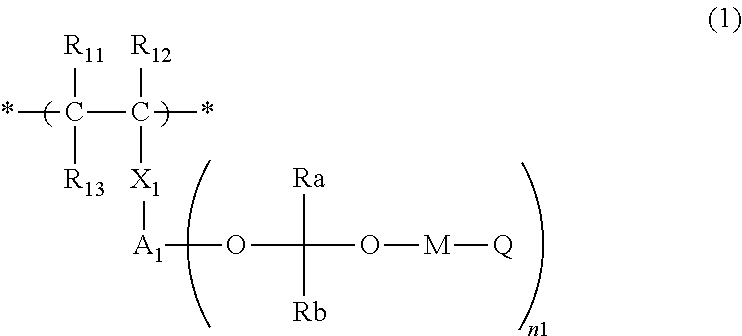

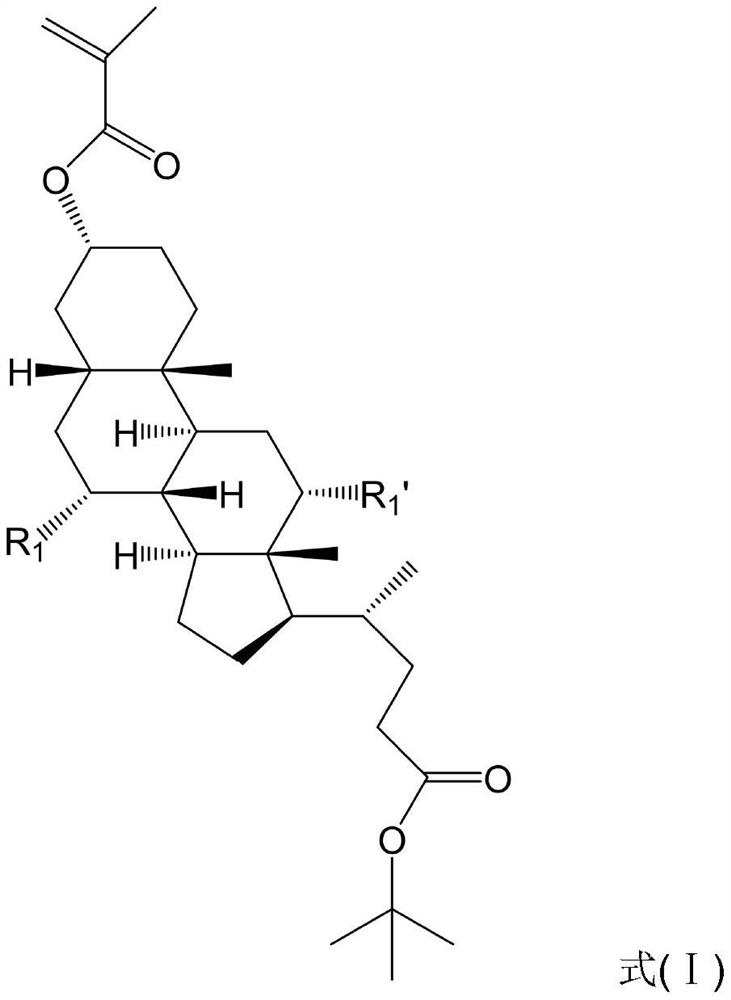

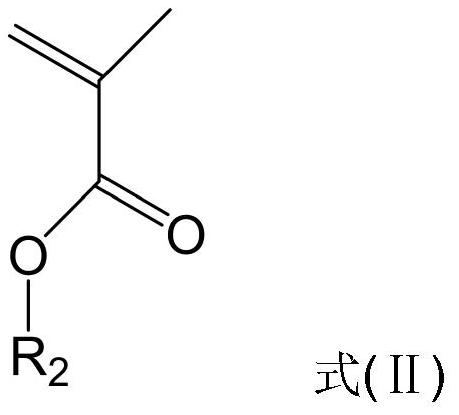

193nm photoresist film-forming resin, preparation method thereof and positive photoresist composition

PendingCN114874384AImprove hydrophilicityImprove solubility contrastPhotomechanical apparatusPolymer sciencePhotoacid generator

The invention discloses 193nm photoresist film-forming resin, a preparation method thereof and a positive photoresist composition, and belongs to the technical field of semiconductor microelectronic chemistry. The 193nm positive photoresist contains film-forming resin and a photoacid generator, and the film-forming resin contains the following components in percentage by mole: 5-40% of a composition unit containing a cholic acid derivative; 10%-50% of a constituent unit containing a polar group; 10%-40% of a unit containing an acid-sensitive group; the cholic acid derivative unit is at least one compound conforming to a chemical general formula (I); the constituent unit of the polar group refers to at least one compound conforming to a chemical general formula (II); the acid-sensitive group unit is at least one compound conforming to a chemical general formula (III). The cholic acid-containing derivative is introduced as a film-forming resin unit, so that the adhesiveness, the dissolution inhibition effect and the graphic contrast of the film-forming resin can be improved, and the line edge roughness is reduced.

Owner:南通林格橡塑制品有限公司 +1

Pattern transfer method

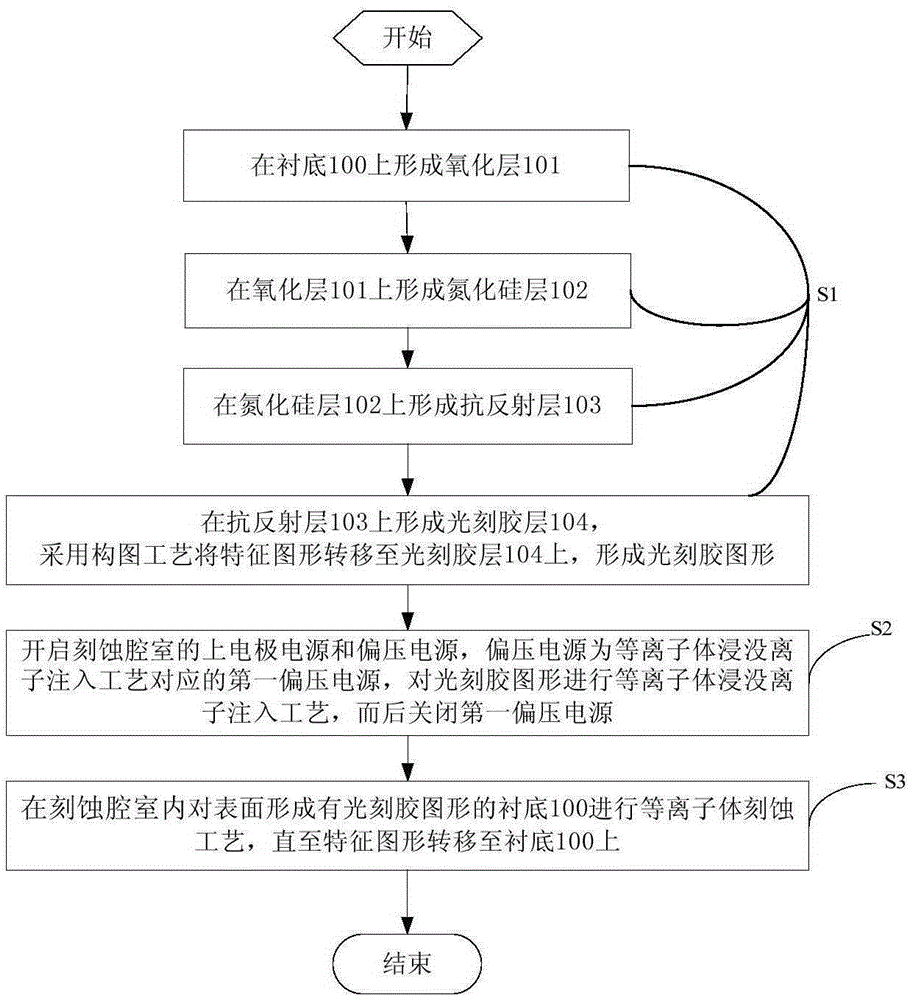

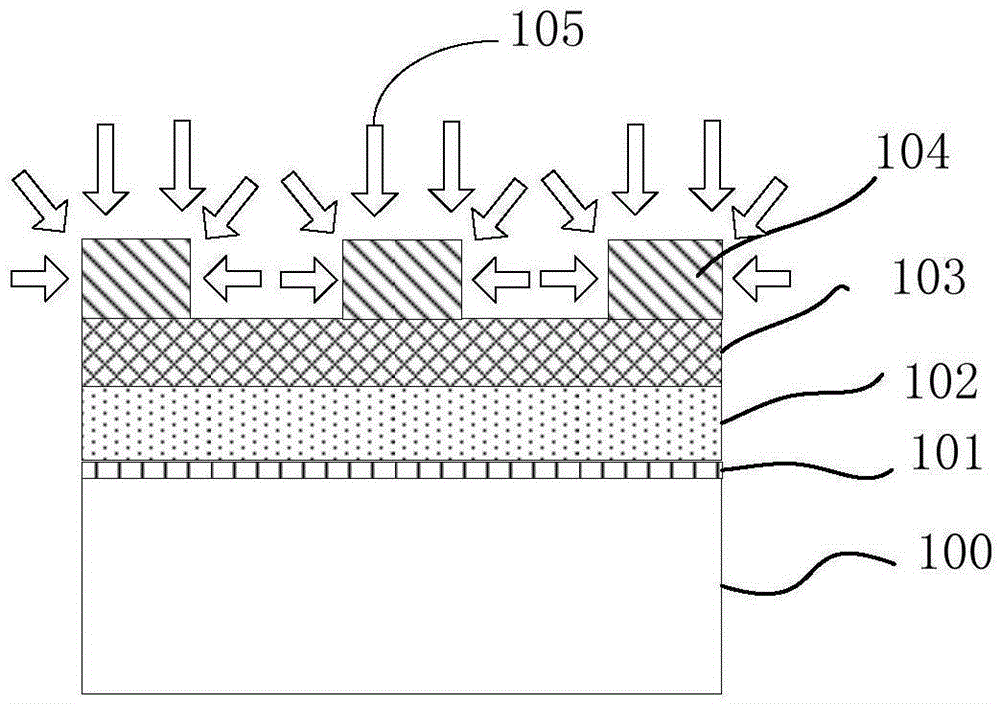

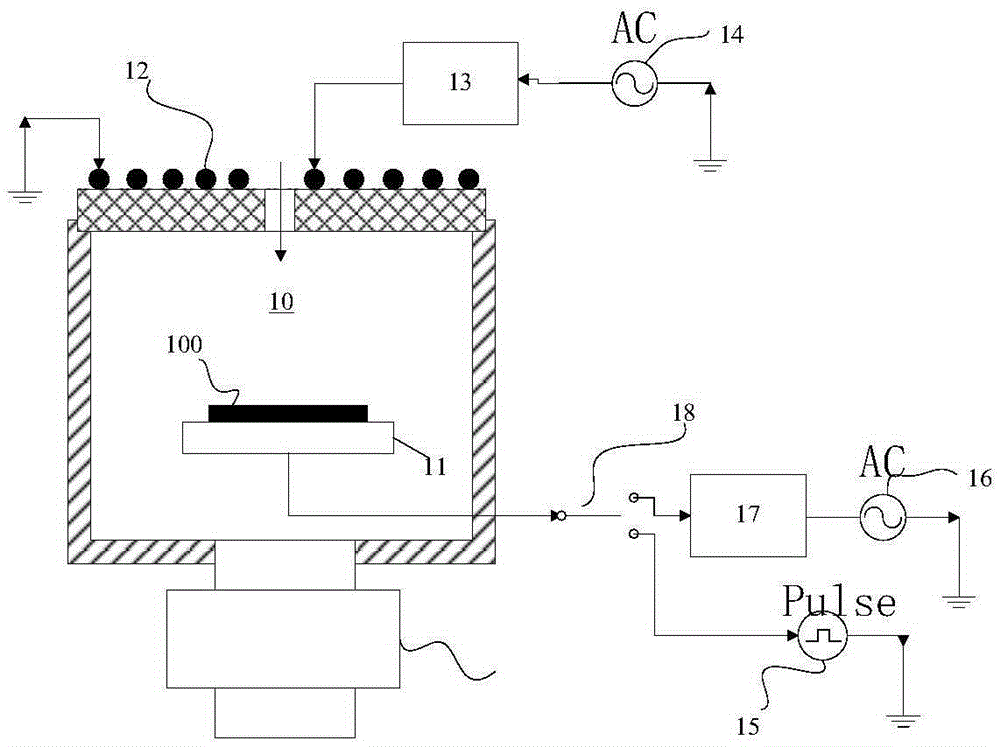

ActiveCN106571291ALow costHigh hardnessSemiconductor/solid-state device manufacturingPlasma-immersion ion implantationEngineering

The invention provides a pattern transfer method, which is used for transferring a characteristic pattern to a substrate. The method comprises the following steps: S1) forming a photoresist layer on the substrate, and transferring the characteristic pattern to the photoresist layer through the composition technology to form a photoresist pattern; S2) turning on an excitation power supply and a grid bias power supply in an etching chamber, wherein the grid bias power supply is a first grid bias power supply corresponding to plasma immersion ion implantation technology, carrying out plasma immersion ion implantation on the photoresist pattern, and then, turning off the first grid bias power supply; and S3) carrying out plasma etching on the substrate, on the surface of which the photoresist pattern is formed, in the etching chamber until the characteristic pattern is transferred to the substrate. The pattern transfer method can reduce line width roughness of each line of the photoresist pattern in situ, so that process is simplified to a great extent, process time is reduced and device cost is reduced; and besides, line width roughness of each line of the photoresist pattern can be further reduced, thereby facilitating accurately transferring the pattern to the substrate.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Formation method of semiconductor structure

ActiveCN105575787BSmall roughnessIncreased wide roughnessSemiconductor devicesGrid patternSemiconductor structure

A formation method of a semiconductor structure is disclosed. The method comprises the following steps of providing a surface possessing a grid film substrate, wherein a grid pattern film including a hard mask layer material layer and a silicon material layer covers a grid film surface; forming a pattern layer on a grid pattern film surface; taking the pattern layer as a mask layer and etching a part of the grid pattern film to form a grid pattern layer, wherein the grid pattern layer comprises a hard mask layer and a silicon layer located on a hard mask layer surface; and a sidewall surface of the silicon layer, which is vertical to a first direction, possesses first line width roughness; carrying out repairing etching processing on the silicon layer sidewall vertical to the first direction so that the silicon layer sidewall surface possesses second line width roughness less than the first line width roughness; taking the grid pattern layer as the mask layer to etch a grid film and forming a grid on a substrate surface; and forming a source area and a leakage area in the substrate of two sides of a grid sidewall vertical to the first direction. By using the method, the line width roughness of the grid pattern layer is reduced so that formed grid quality is increased and electric performance of the semiconductor structure is optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Biphenyl molecular glass and preparation method thereof

InactiveCN102557930BReduce line width roughnessNo swellingOrganic compound preparationCarboxylic acid esters preparationPotassium iodineTert butyl

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

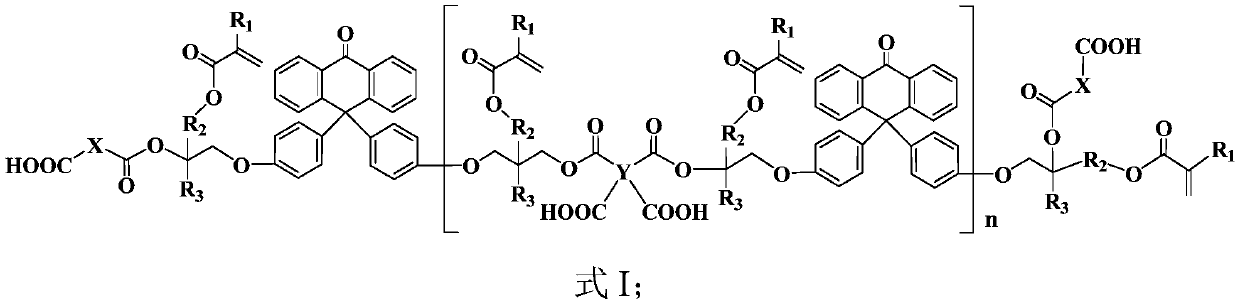

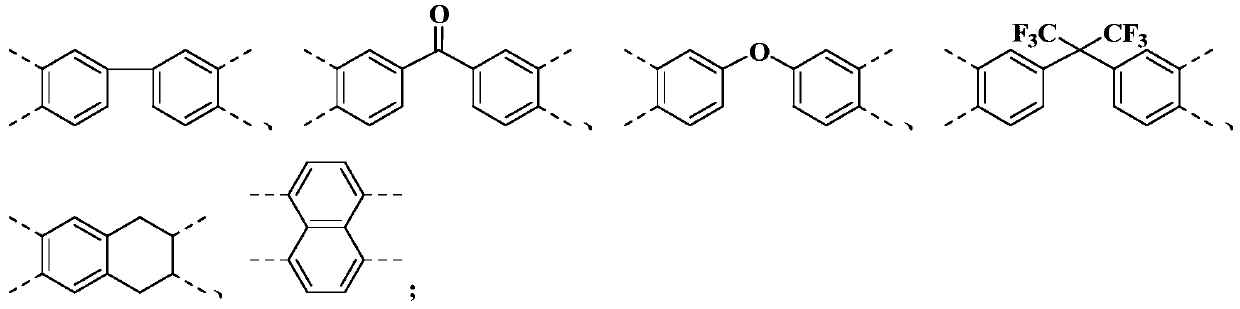

Photosensitive resin, preparation method and application thereof

PendingCN111007699AExcellent developabilityImprove adhesionOptical filtersPhotomechanical apparatusPolymer scienceLight irradiation

The invention provides photosensitive resin, a preparation method and an application thereof. The photosensitive resin has a structure as shown in a formula I, is an alkali-soluble resin, and heat resistance, stability and photosensitivity can be remarkably improved through a special design of a molecular structure and introduction of anthracene ketone groups. The photosensitive resin can be subjected to a chemical crosslinking reaction under light irradiation to form a stable condensate insoluble in an alkali liquor so that a photoresist composition containing the photosensitive resin has excellent developing performance, adhesion, pattern precision and thermal stability. The photosensitive resin is suitable for a negative photoresist composition and is especially suitable for photoresistfor a black matrix, and a pattern obtained after exposure and development has good collimation, resolution and the excellent thermal stability. The photosensitive resin can be used for preparing a high-precision microstructure, and a stability requirement of the photoresist for multiple high-temperature baking processes in a processing process can be fully met.

Owner:FUYANG XINYIHUA MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com