193nm photoresist film-forming resin, preparation method thereof and positive photoresist composition

A film-forming resin and photoresist technology, applied in the field of photoresist, can solve the problems of inability to completely prevent the dissolution promotion, limited effect, acid diffusion, etc., achieve good dispersion and dissolution inhibition effect, improve solubility contrast, The effect of enhancing the hydrophilicity of the resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

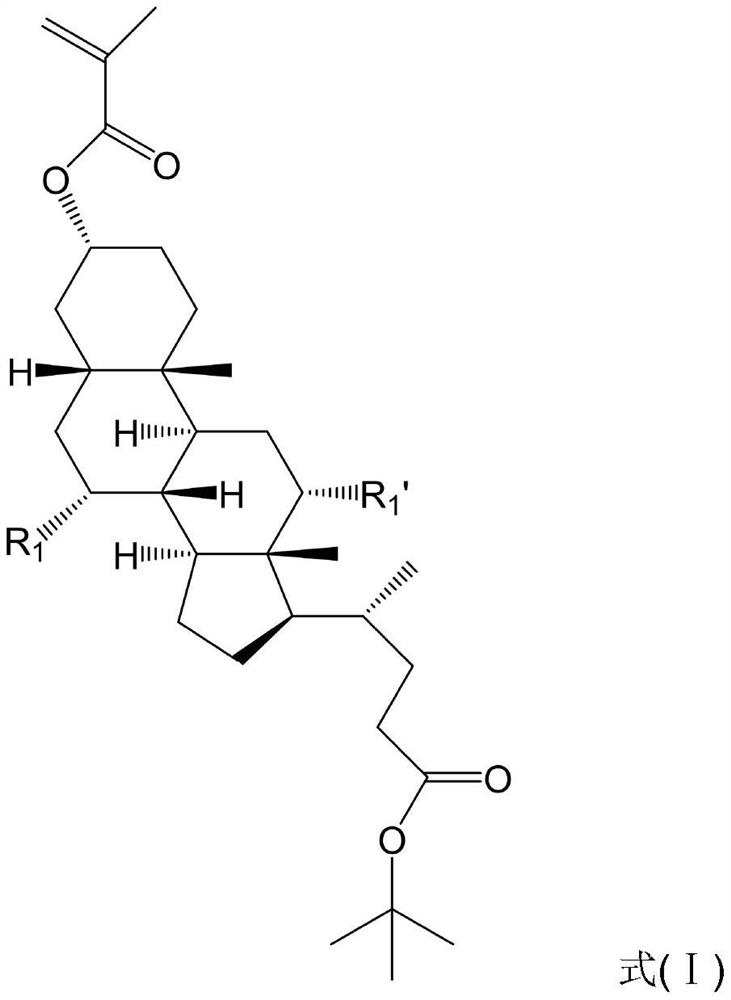

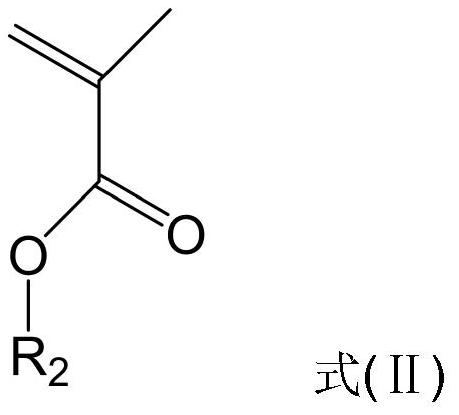

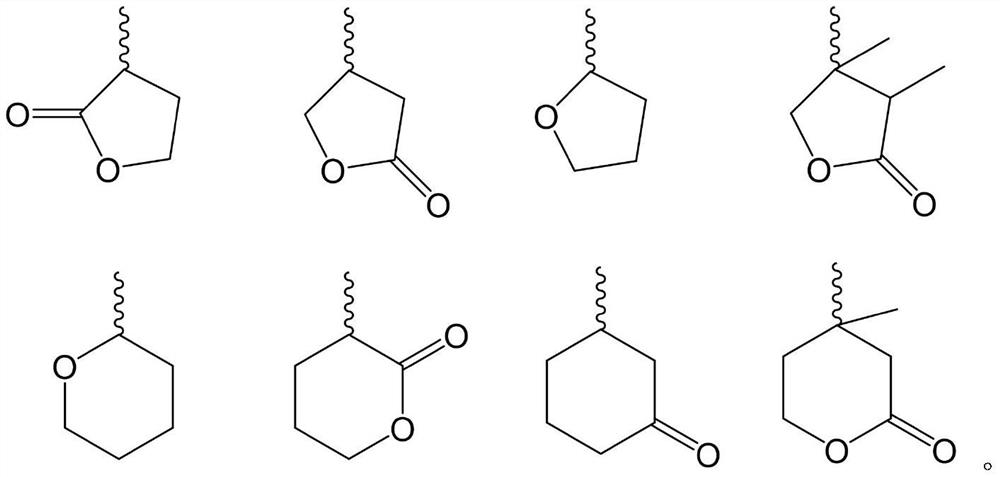

[0033] In a nitrogen-filled state, 10 g of lithocholic acid methacrylate (monomer I, formula I) protected by T-boc, 60 g of valerolactone methacrylate (monomer II, formula II), 30 g of methyl methacrylate were mixed with Add adamantyl acrylate (monomer III, formula III) and 500 mL of tetrahydrofuran into a 1000 mL four-neck reaction flask, then add 2 g of azobisisobutyronitrile (AIBN) dropwise, stir well, heat to 60-70 °C, keep After 3 hours, the reaction was quickly quenched with an ice bath and cooled to room temperature, precipitated in ether, filtered through a Buchner funnel, and the filter cake was dried. The filter cake was dissolved in tetrahydrofuran, precipitated in methanol again, filtered and placed in a vacuum drying oven at 50°C for 48 hours to obtain the photoresist film-forming resin 1#, and the weight-average molecular weight Mw of the film-forming resin was measured by GPC =27300, molecular weight distribution PDI=1.87.

[0034]

Embodiment 2

[0036] In a nitrogen-filled state, 20 g of lithocholic acid methacrylate (monomer I, formula I) protected by T-boc, 50 g of valerolactone methacrylate (monomer II, formula II), 30 g of 3- Hydroxyadamantanol methacrylate (monomer III, formula III) and 500 mL of tetrahydrofuran were added to a 1000 mL four-neck reaction flask, and then 2 g of azobisisobutyronitrile (AIBN) was added dropwise, fully stirred, and heated to 60~ 70° C. for 4 hours, then the reaction was quickly stopped with an ice bath and cooled to room temperature, precipitated in ether, filtered with a Buchner funnel, and the filter cake was dried. The filter cake was dissolved in tetrahydrofuran, precipitated in methanol again, filtered and then placed in a vacuum drying oven at 50°C for 48 hours to obtain the photoresist film-forming resin 2#. The weight-average molecular weight Mw of the film-forming resin was measured by GPC =28700, molecular weight distribution PDI=1.75.

[0037]

Embodiment 3

[0039] In the state of being filled with nitrogen, 30 g of chenodeoxycholate methacrylate (monomer I, formula I) protected by T-boc, 40 g of mevalonolide methacrylate (monomer II, formula II) were mixed together. ), 30g of 3-hydroxyadamantanol methacrylate (monomer III, formula III) and 500mL of methyl ethyl ketone were added to a 1000mL four-neck reaction flask, and then 2g of azobisisobutyronitrile (AIBN) was added dropwise. ), fully stirred, heated to 60 ~ 70 ℃, kept for 5 hours, and then quickly stopped the reaction with an ice bath and fell to room temperature, precipitated in ether, filtered with a Buchner funnel, and dried the filter cake. The filter cake was dissolved in methyl ethyl ketone, precipitated in methanol again, filtered and dried in a vacuum drying oven at 50°C for 48 hours to obtain the photoresist film-forming resin 3#. The weight average molecular weight Mw=31300, and the molecular weight distribution PDI=1.87.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com