Photosensitive resin, preparation method and application thereof

A photosensitive resin and reaction technology, applied in the field of photosensitive materials, can solve the problems of affecting the graphics accuracy of the development effect, increasing the difficulty of the development operation, and the residue of heat-resistant resin, so as to meet the stability requirements, excellent heat resistance, good heat resistance, etc. photosensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

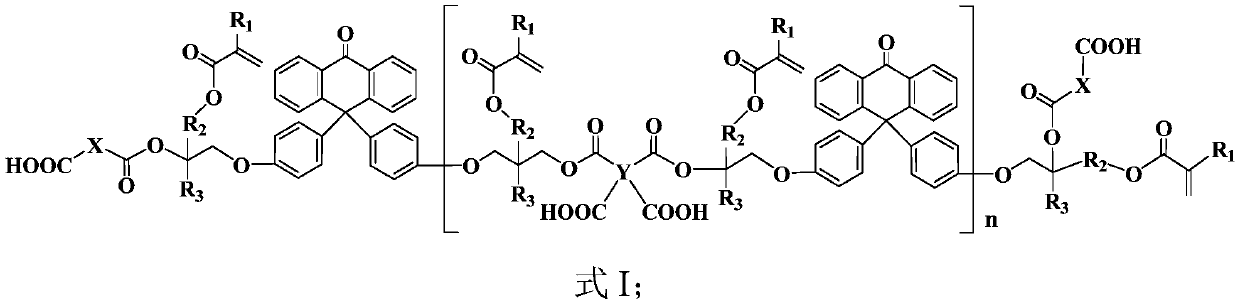

[0055] This embodiment provides a kind of photosensitive resin, the structure is as follows:

[0056]

[0057] Its preparation method comprises the following steps:

[0058]

[0059] Put 190g of bisphenol anthrone and 700g of epichlorohydrin in a 1000mL reaction bottle, add 50g of sodium hydroxide, and react at room temperature for 24h; add hydrochloric acid to neutralize, wash with water until neutral, spin dry, and recrystallize from ethanol to obtain bisphenol anthracene Keto glycidyl ether 200g, the yield is 80%.

[0060]

[0061] Bisphenol anthrone glycidyl ether 25g, acrylic acid 72g and catalyst triphenylphosphorus PPh obtained by step (1) 3 Placed in a reaction kettle, with propylene glycol methyl ether acetate PMA as solvent, under N 2 The reaction was carried out at 120° C. for 24 hours under protection; after the reaction, the reaction liquid was washed with water until neutral, and spin-dried to obtain 22 g of bisphenol anthrone glycidyl ether diacrylate...

Embodiment 2

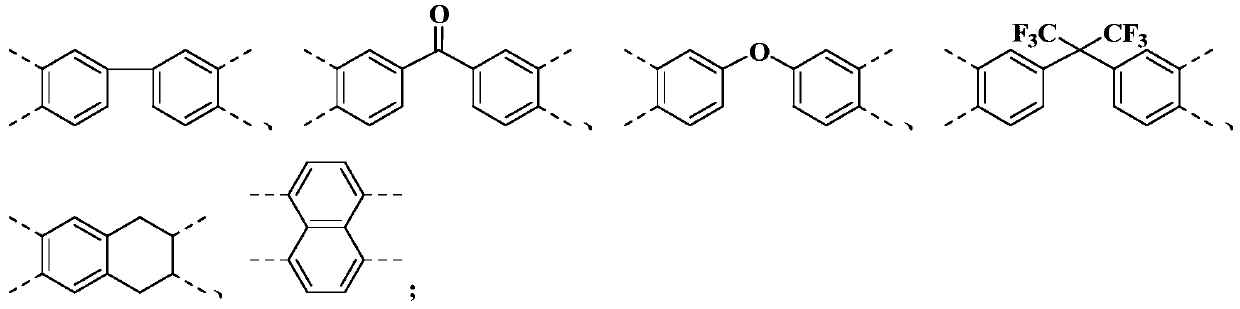

[0064] This embodiment provides a kind of photosensitive resin, the structure is as follows:

[0065]

[0066] The difference between its preparation method and the preparation method in Example 1 is that the tetrahydrophthalic anhydride in step (3) is replaced by an equimolar amount of hexahydrophthalic anhydride to obtain the photosensitive resin.

Embodiment 3

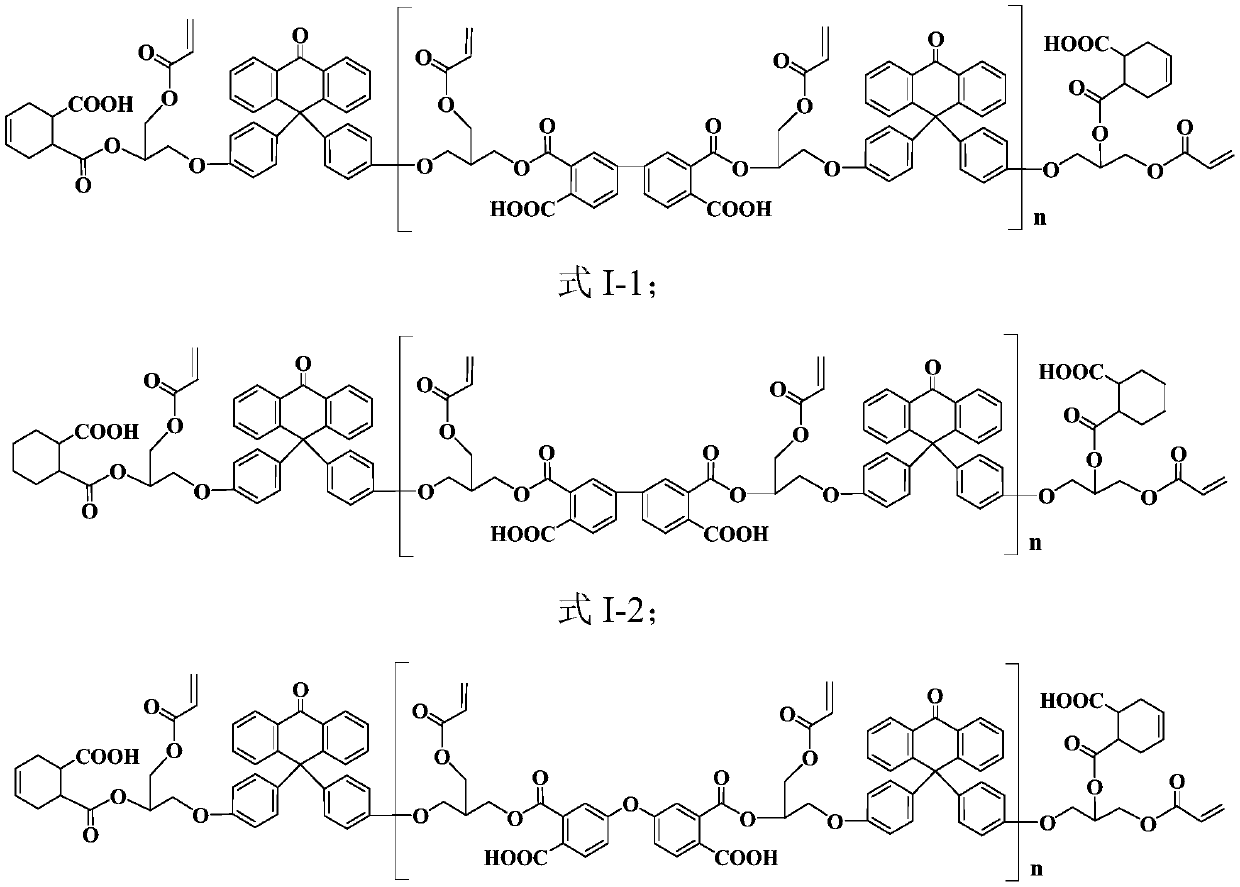

[0068] This embodiment provides a kind of photosensitive resin, the structure is as follows:

[0069]

[0070] The difference between its preparation method and the preparation method in Example 1 is that the biphenyltetracarboxylic dianhydride in step (3) is mixed with an equimolar amount of 3,3',4,4'-diphenylmethyl ether tetraacid di anhydride (that is, oxydiphenyltetracarboxylic dianhydride) to obtain the photosensitive resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com