Cable having versatile space portion

A space department, multi-functional technology, applied in the direction of insulated cables, cable installation, cable layout between relative moving parts, etc., can solve the problems of unable to maintain the correct bending radius, difficult to install, unstable movement, etc., to achieve improved Multifunctional use efficiency, prevention of wire damage, and effect of preventing wire knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the cable having a multifunctional space portion according to the present invention will be described in detail with reference to the drawings.

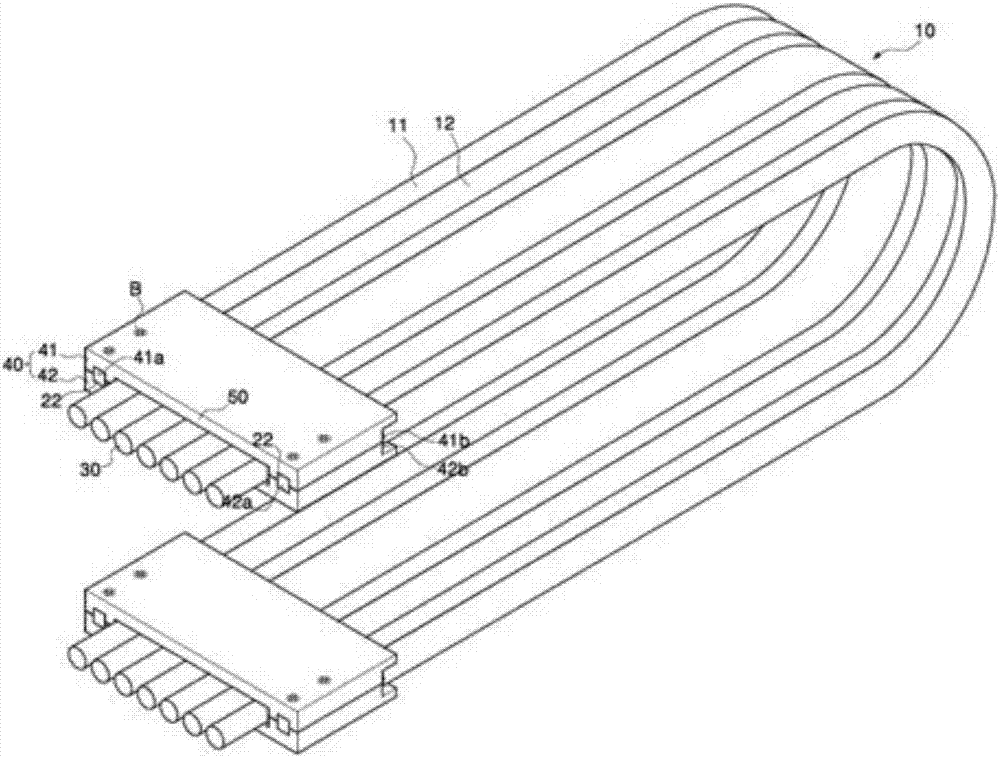

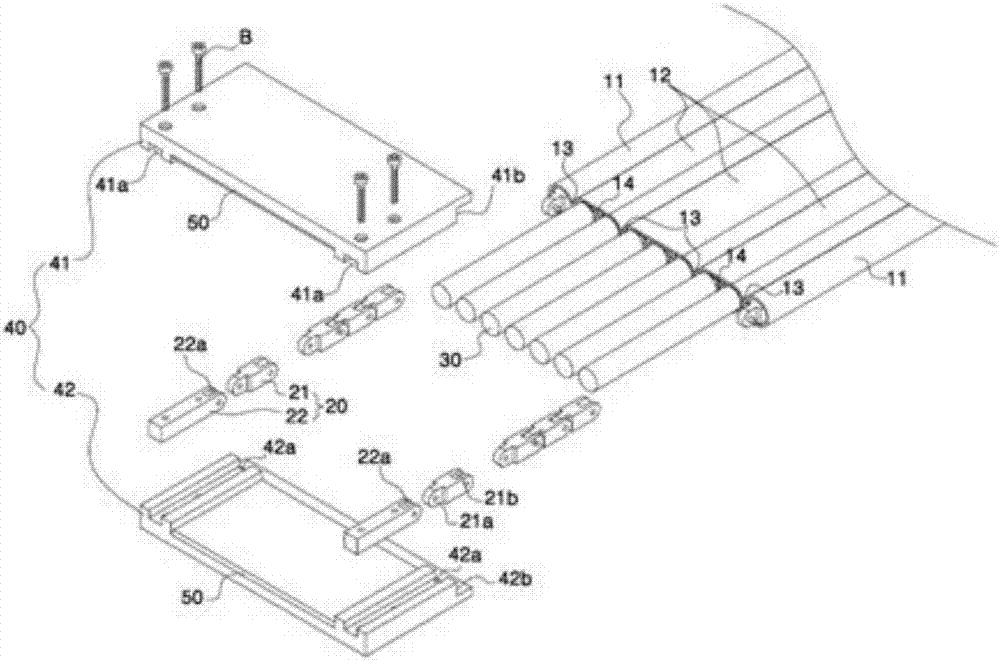

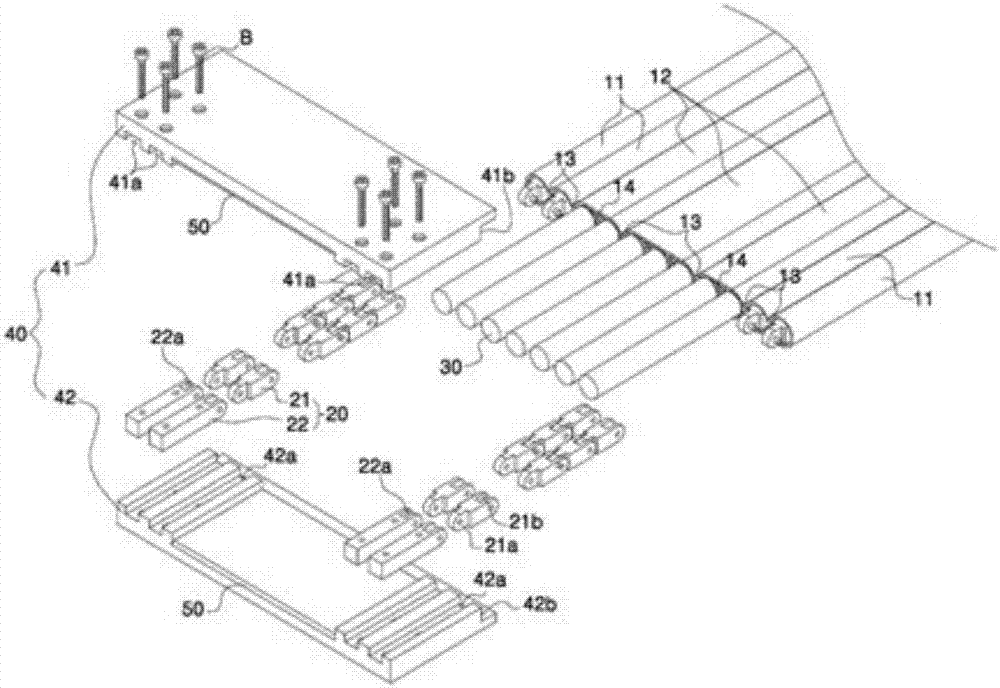

[0031] figure 1 To illustrate a perspective view of a cable with a multifunctional space part according to the first embodiment of the present invention, FIG. 2 is an exploded perspective view illustrating a cable with a multifunctional space part according to the first embodiment of the present invention.

[0032] Such as figure 1 , shown in 2, the first embodiment of the present invention has the electric wire pod (Pod, 11) that multifunctional space part cable (10) is retracted into support member inside, and the electric wire inserting part (12) that internally retracts electric wire, and inserts The support member (20) inserted into the wire pod (11), the wires (30) inserted into the wire insertion portion (12), and the pipe clamp (40) fixed to the support member (20) are constituted.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com