Desulfurizer slurry preparation system

A preparation system and desulfurizer technology, applied in the direction of mixers, mixing methods, fluid mixers, etc., can solve the problems of inability to run continuously for a long time, high labor intensity, and low degree of automation, so as to maintain high-efficiency filtration capacity, The effect of high degree of automation and continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

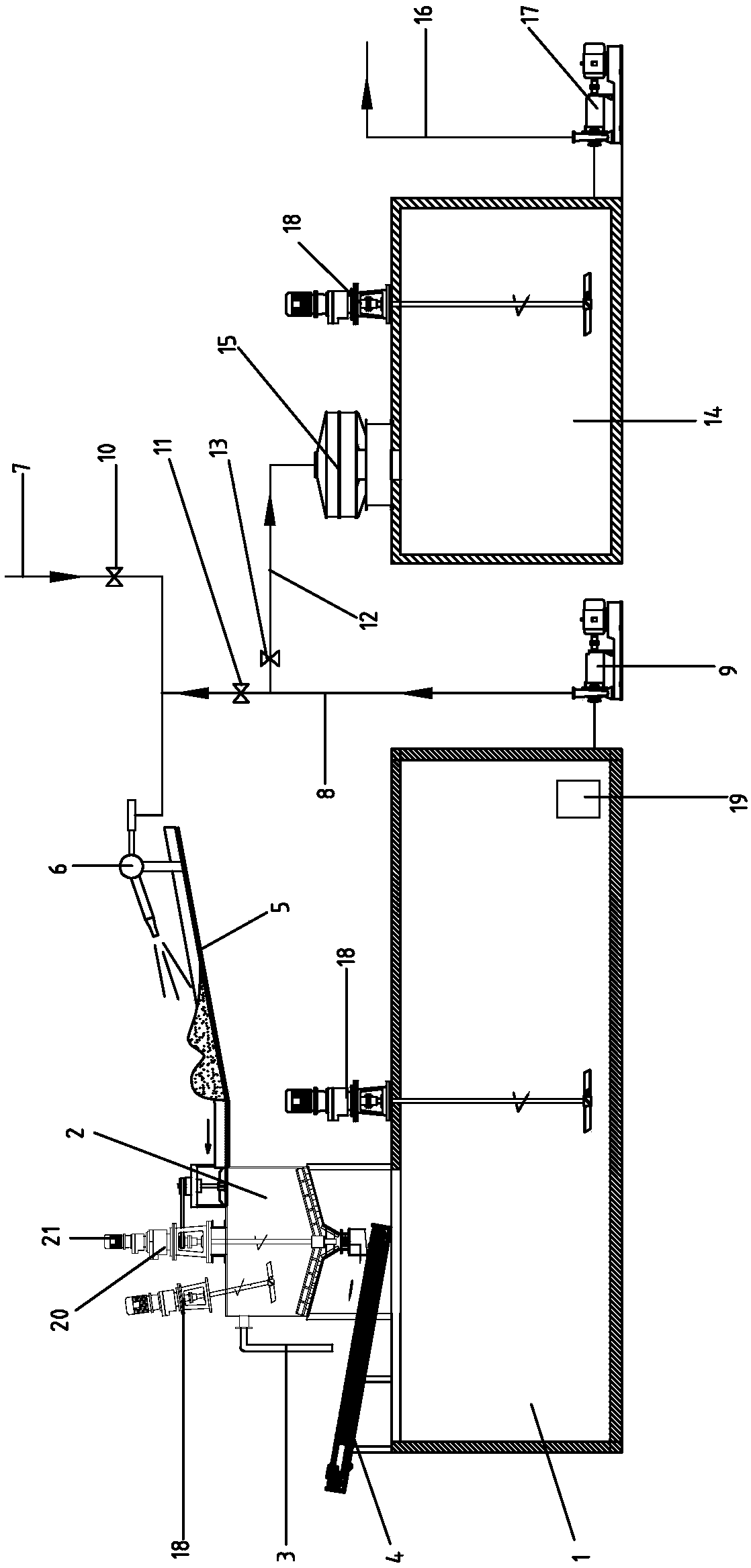

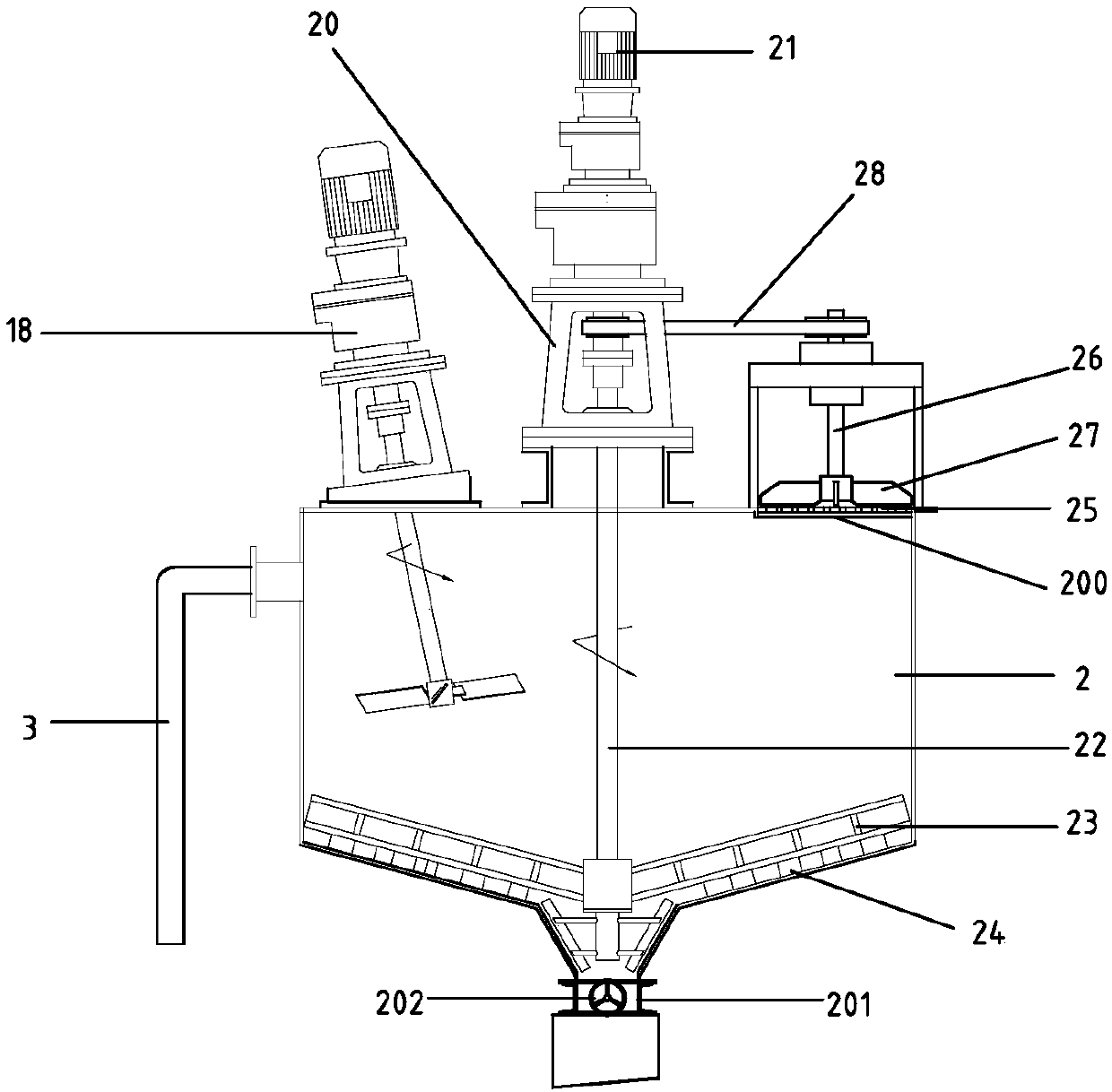

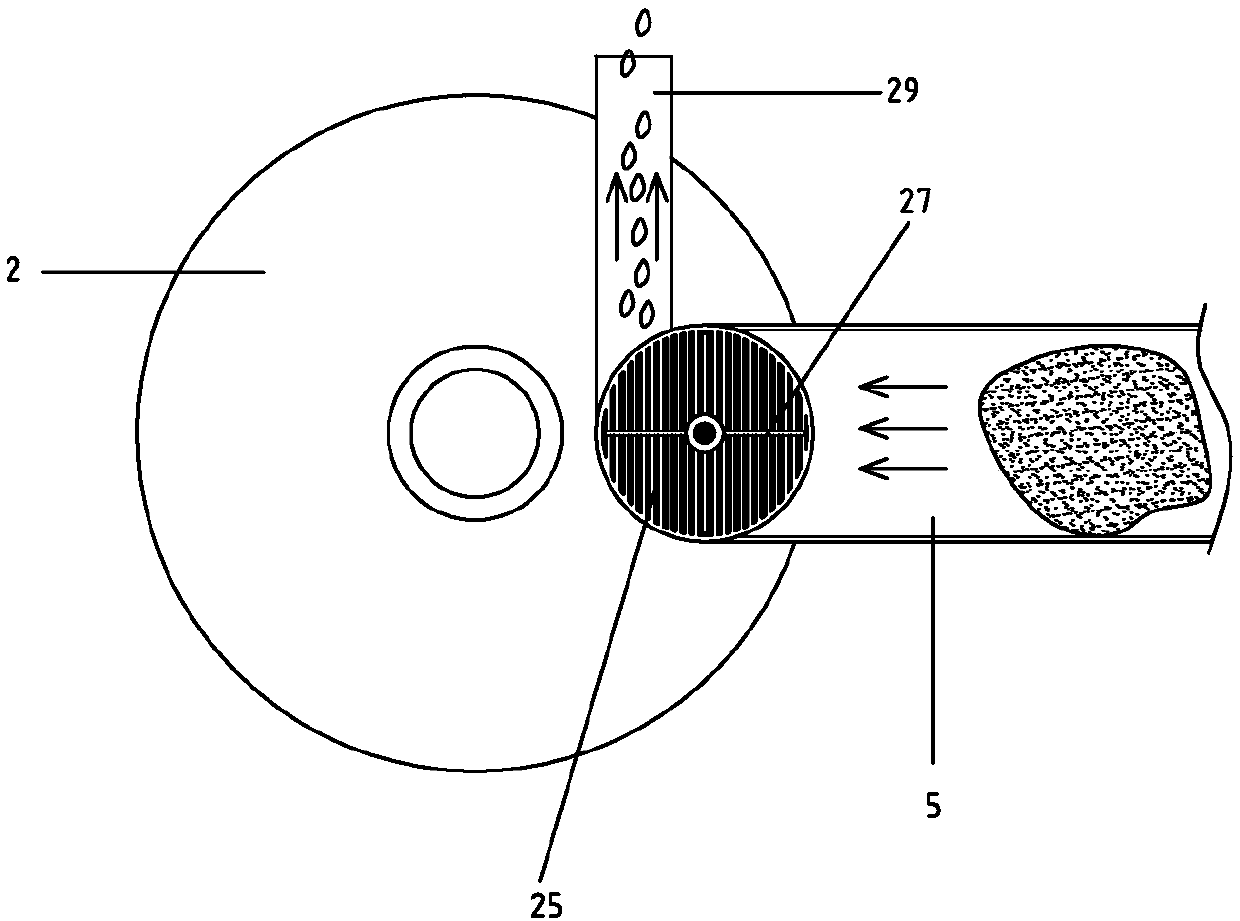

[0025] Such as figure 1A desulfurizer slurry preparation system shown includes a slurry tank 1 and a slurry tank 2 arranged above the slurry tank. The top of the slurry tank 2 is provided with a feed port 200, and the bottom of the slurry tank is provided with an outlet. Material passage 201, valve 202 is arranged on the discharge passage, overflow pipe 3 is provided on the side of the upper end of the pulping tank, and a mesh belt filter 4 is arranged between the lower end of the pulping tank and the upper end of the slurry tank, and the mesh belt filter The distribution of the machine is inclined, the inclination angle of the mesh belt filter is 5°-20°, the lower end of the mesh belt filter is located below the discharge channel, the upper end of the mesh belt filter is located outside the slurry pool, and the outlet of the overflow pipe The end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com