Unmanned automatic rebar bending machine

A technology of bending device and steel bar, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of aggravating the fatigue of workers, bone diseases of workers, and increasing labor costs, and achieves the improvement of practical performance and operational performance. The effect of alleviating recruitment difficulties and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

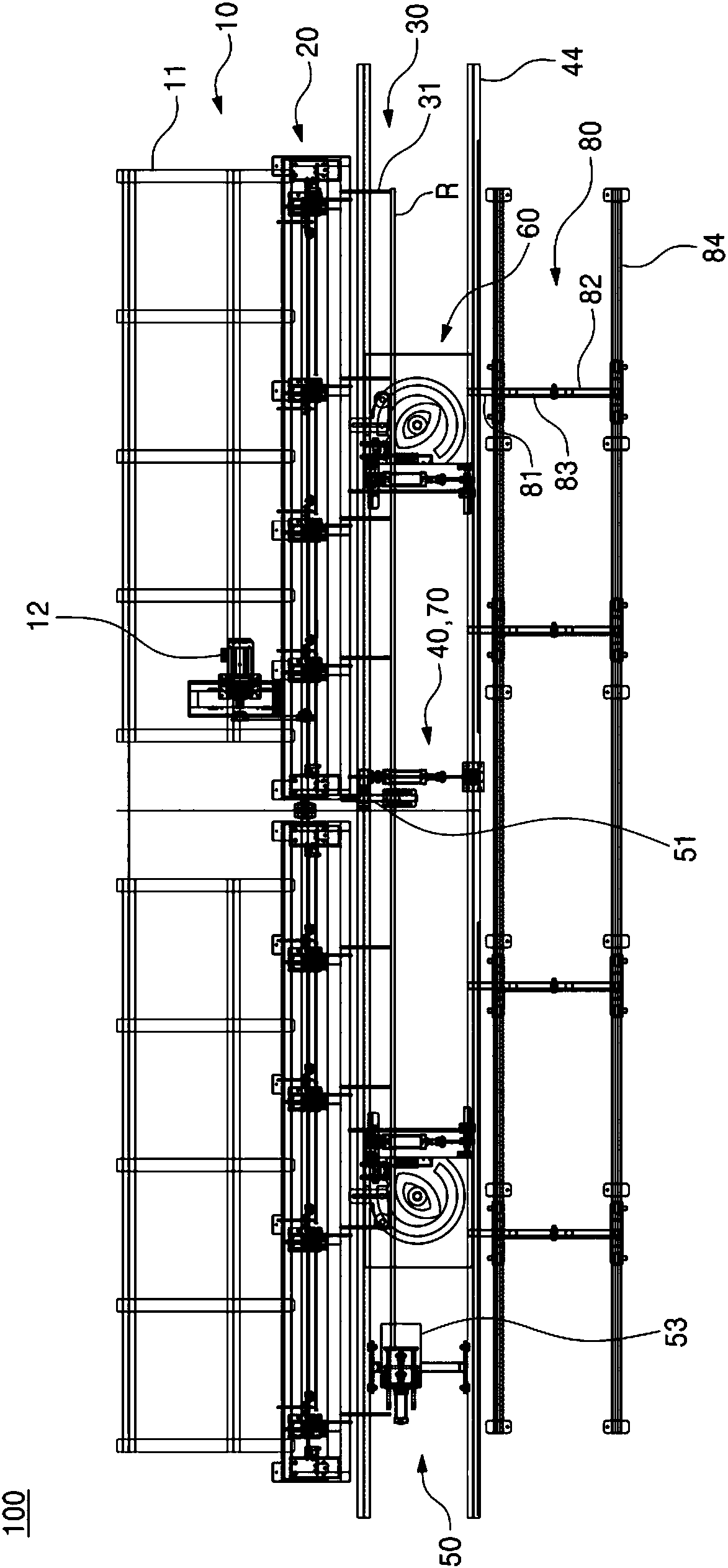

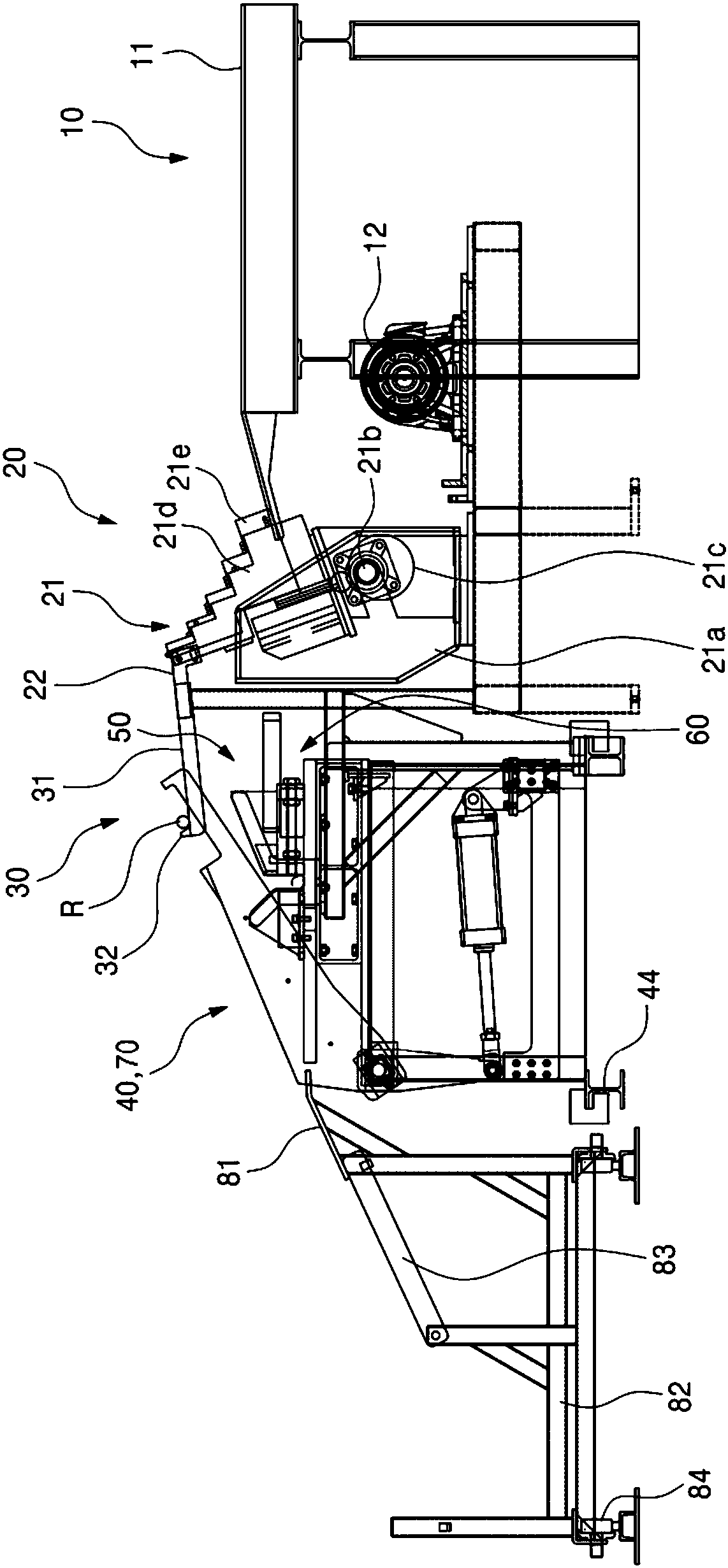

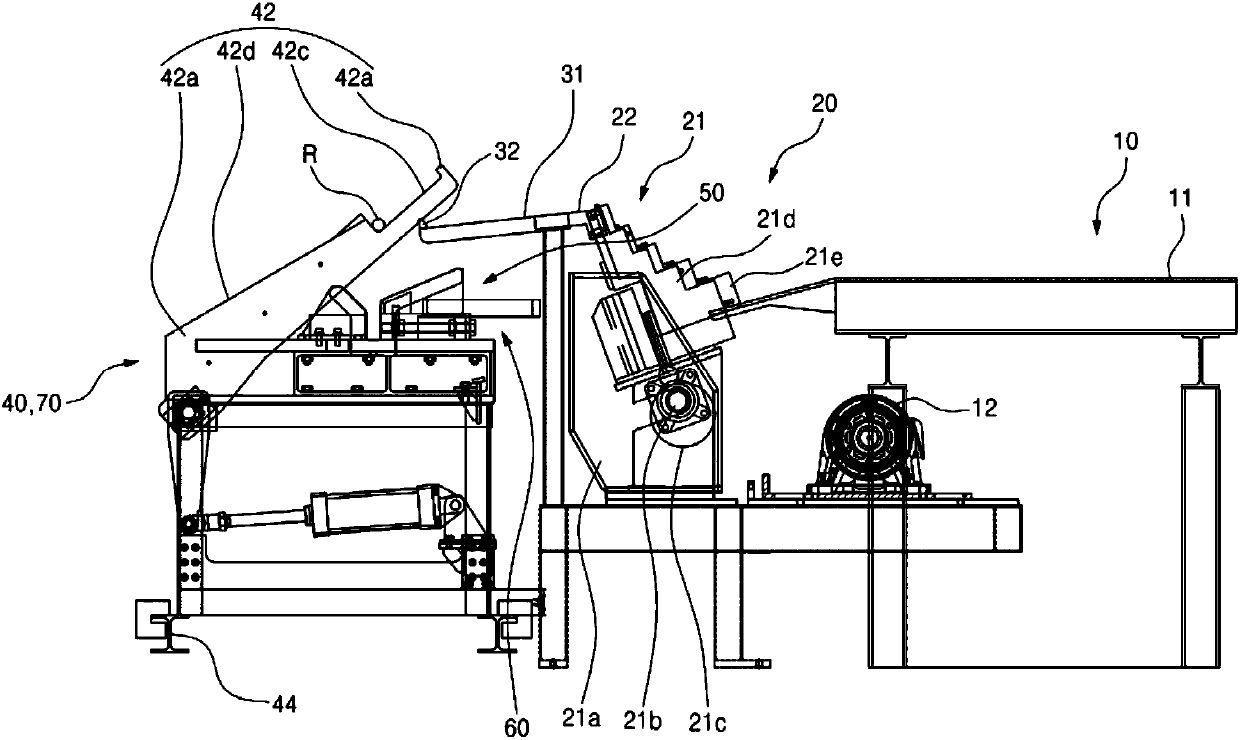

[0085] The invention relates to an unmanned automatic bending device for steel bars used when bending bar-shaped high-weight steel bars to a set angle according to the application.

[0086] In particular, the unmanned automatic steel bar bending device applicable to the present invention is characterized in that it can quickly and accurately bend high-weight steel bars in an unattended state.

[0087] The features described above are realized by the structure as follows: the high-weight steel bars supplied by the supply conveying device are separated into a set quantity by using the separation transfer machine, and are neatly loaded into the loading table, and then the connecting rod Under the action of the arm, the steel bar is put into the set position under the guidance of the central guide block and the head arrangement stopper, and then the steel bar is bent at the set angle under the action of the bending head, and then the steel bar is bent at the set angle again. Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com