Novel clamp type butterfly valve

A clamp butterfly valve, a new type of technology, applied in the direction of lift valve, valve details, valve device, etc., can solve problems such as a large number of casting workers and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

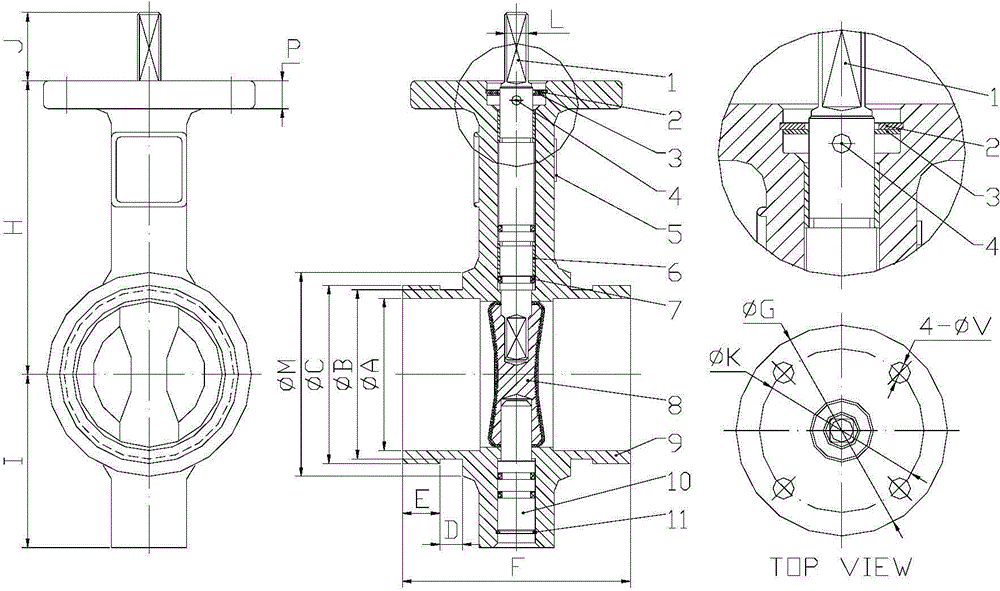

[0010] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

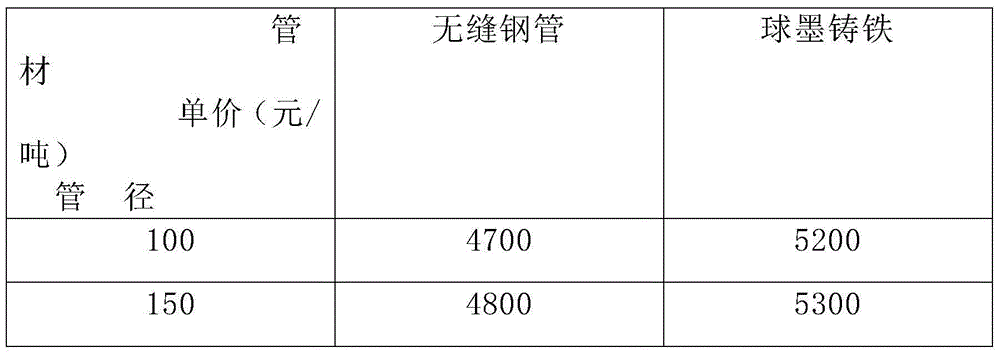

[0011] The inventive embodiment of the present invention provides a new type of seamless steel pipe material suitable for the body of a clamp butterfly valve. After the seamless steel pipe is cut by the cutting machine according to the valve specification and size, it is finished and polished by the machine tool, and then the valve body and the valve neck are welded. The sand-cast cast iron valve body has the disadvantages of sand holes, low pressure bearing, and high production cost. . With the valve body provided by the embodiment of the present invention, the metal flow line is complete, which can ensure that the parts have good mechanical properties and long service life, which are incomparable to castings.

[0012] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com