Solid wood parquet wall decoration board

A solid wood composite and decorative panel technology, applied in the field of building decorative materials, can solve the problems of unsatisfactory decorative effect, complex structure and high cost, and achieve the effects of good waterproof and flame retardant effect, simple structural composition and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

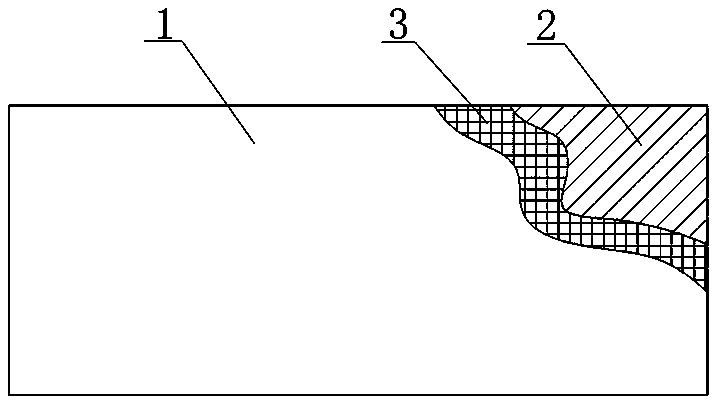

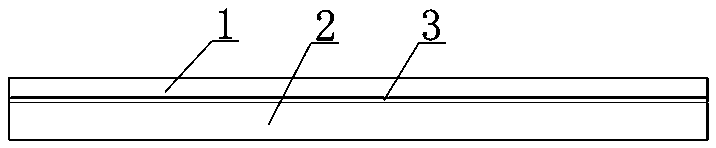

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, a kind of solid wood composite wall decoration board according to the present invention is composed of a solid wood veneer surface layer 1 and a cement fiberboard bottom layer 2 through a PUR high-strength viscosity waterproof bonding glue 3, and the solid wood veneer surface layer 1 is After high-temperature anticorrosion and anti-insect treatment with veneer, vacuum impregnation treatment and drying with flame retardant, press and paste on at least one surface of cement fiber board 2 with PUR high-strength viscosity waterproof adhesive 3; said cement fiber board 2 is made of cement It is mixed with wood fiber and paper fiber and then cast with a mold under high pressure, wherein the thickness of the surface layer 1 of solid wood veneer is 0.35-4mm, and the thickness of the bottom layer 2 of cement fiber board is 4-6mm.

[0014] The high-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com