Gas chromatography sample introduction device capable of realizing self cleaning of flow distribution pipeline

A gas chromatography and sampling device technology, applied in the field of analytical instruments, can solve the problems of cleanliness affecting analytical precision, expensive, time-consuming, etc., and achieves the effect of avoiding the procedure of the sampling port, improving the service life and making the manufacturing process simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

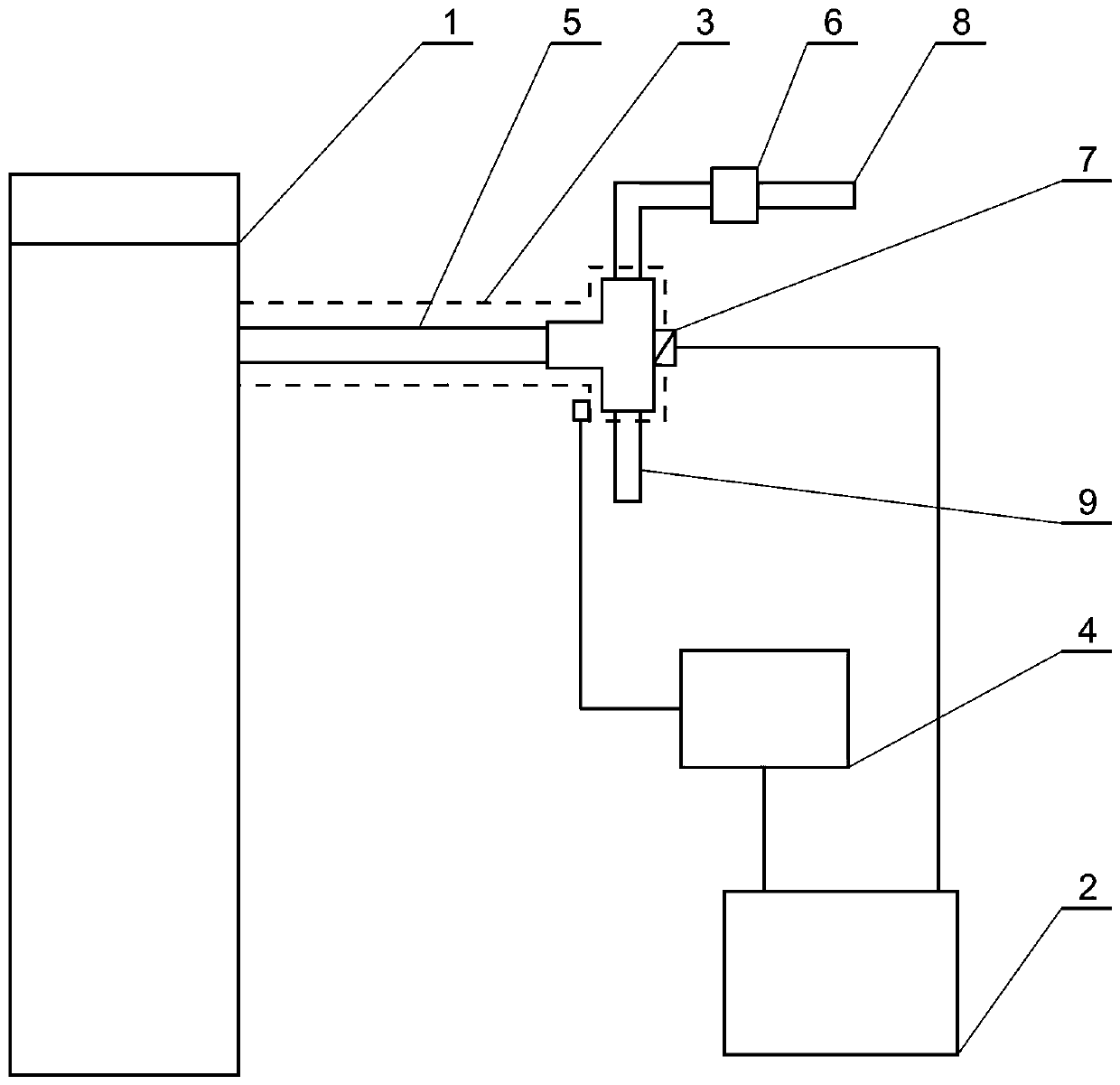

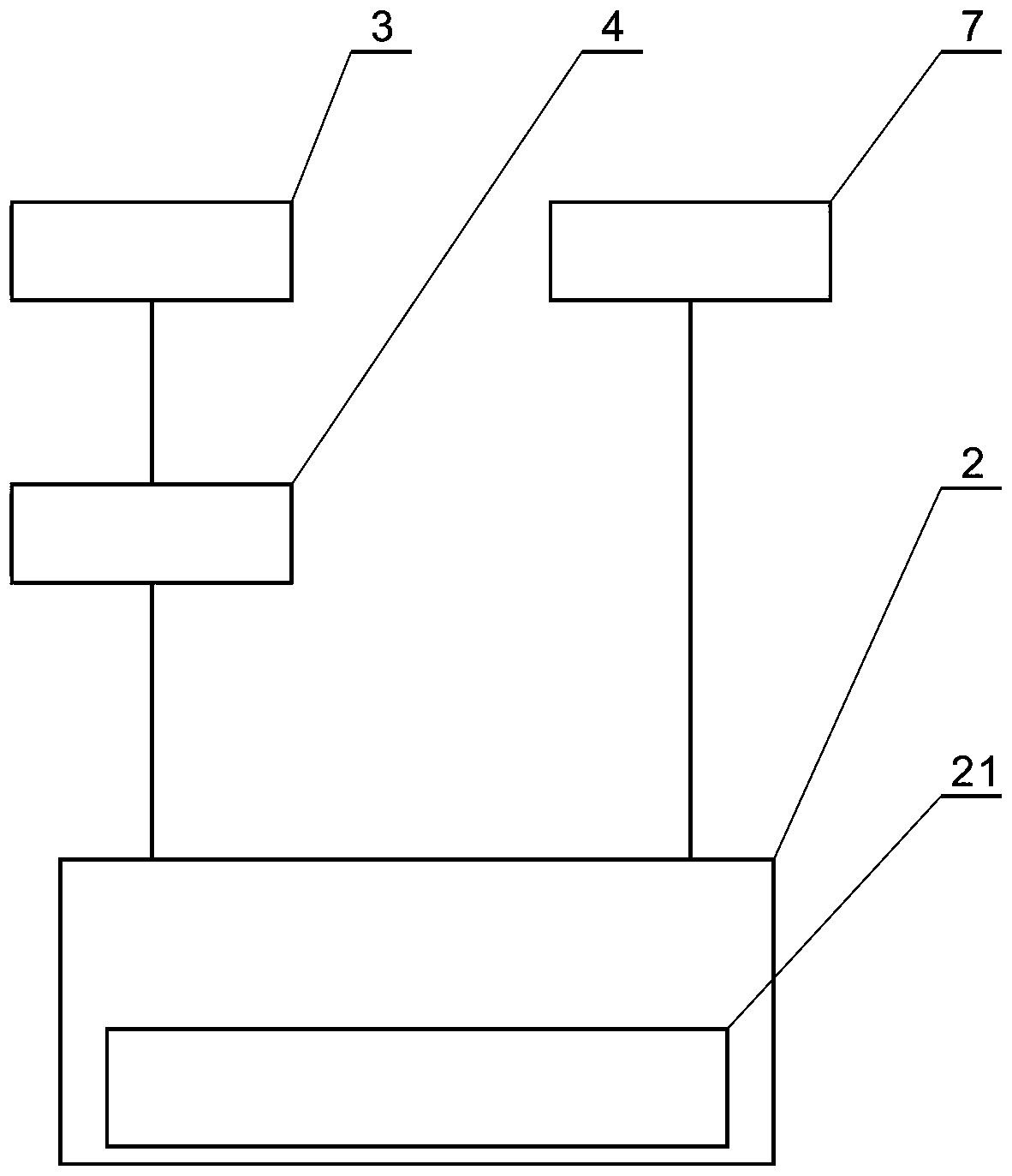

[0027] refer to figure 1 , figure 2 , this example includes:

[0028] A splitter 1 provided with a split pipeline 5 and a sample inlet;

[0029] A gas chromatograph control unit 2 provided with two control ports;

[0030] A constant temperature heating belt 3 provided with a temperature control switch;

[0031] A temperature controller 4 provided with a command port and a control port;

[0032] A three-way stop valve 7 with an electromagnetic switch, one input terminal and two output terminals;

[0033] a shunt outlet 8 provided with a filter 6;

[0034] a purge gas outlet 9;

[0035] The input end of the three-way stop valve 7 is connected to the shunt pipeline 5 of the flow divider 1, one output end of the three-way stop valve 7 is connected to the outlet 8 of the shunt pipe provided with a filter 6, and the other output end is connected to the purge gas outlet. 9 connections;

[0036] The constant temperature heating belt 3 is bound on the outer surface of the shun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com