Simple screen plate manufacturing method suitable for pasting chip

A production method and screen technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as difficult to guarantee welding quality, waste of funds and resources, and low production efficiency, and achieve reduced steel mesh scrapping, high production efficiency, and high processing efficiency. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

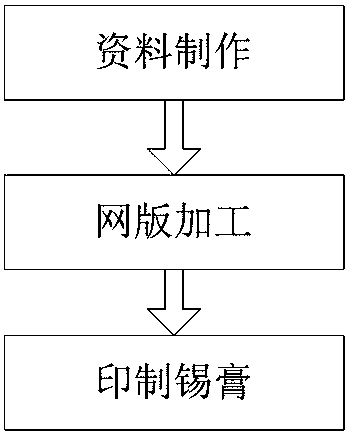

[0024] Such as figure 1 As shown, the invention discloses a method for making a simple screen suitable for patching, comprising the following steps:

[0025] A. Data production, including laser cutting quality production and FR4 board drilling quality production:

[0026] Production of laser cutting data: first copy the steel mesh laser cutting data to the simple screen laser cutting data, and then design a simple screen positioning hole according to the position of the positioning holes around the product, the aperture is ¢1.98mm;

[0027] Production of FR4 board drilling data: design FR4 positioning holes according to the positioning holes around the product, with a diameter of ¢1.98mm;

[0028] B. Processing the screen, cutting two double-sided substrates and FR4 boards of the same size;

[0029] The width of the double-sided substrate is 250mm, the length is 10mm larger than the length of the product, and the thickness is controlled at 50um. The graphic window and positi...

Embodiment 2

[0033] Such as figure 1 As shown, the invention discloses a method for making a simple screen suitable for patching, comprising the following steps:

[0034] A. Data production, including laser cutting quality production and FR4 board drilling quality production:

[0035] Production of laser cutting data: first copy the steel mesh laser cutting data to the simple screen laser cutting data, and then design a simple screen positioning hole according to the position of the positioning holes around the product, the aperture is ¢1.98mm;

[0036] Production of FR4 board drilling data: design FR4 positioning holes according to the positioning holes around the product, with a diameter of ¢1.98mm;

[0037] B. Processing the screen, cutting two double-sided substrates and FR4 boards of the same size;

[0038] The width of the double-sided substrate is 250mm, the length is 10mm larger than the length of the product, and the thickness is controlled at 100u. The graphic window and positi...

Embodiment 3

[0042] Such as figure 1 As shown, the invention discloses a method for making a simple screen suitable for patching, comprising the following steps:

[0043] A. Data production, including laser cutting quality production and FR4 board drilling quality production:

[0044] Production of laser cutting data: first copy the steel mesh laser cutting data to the simple screen laser cutting data, and then design a simple screen positioning hole according to the position of the positioning holes around the product, the aperture is ¢1.98mm;

[0045] Production of FR4 board drilling data: design FR4 positioning holes according to the positioning holes around the product, with a diameter of ¢1.98mm;

[0046] B. Processing the screen, cutting two double-sided substrates and FR4 boards of the same size;

[0047] The width of the double-sided substrate is 250mm, the length is 10mm larger than the length of the product, and the thickness is controlled at 60um. The graphic window and positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com