Container-type plant factory

A container-type and container-based technology, which is applied in the field of container-type plant factories, can solve problems such as difficult to determine the control of the environment, shorten the growth period of plants or vegetables, etc., and achieve the effects of convenient management, extended harvest period, and increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

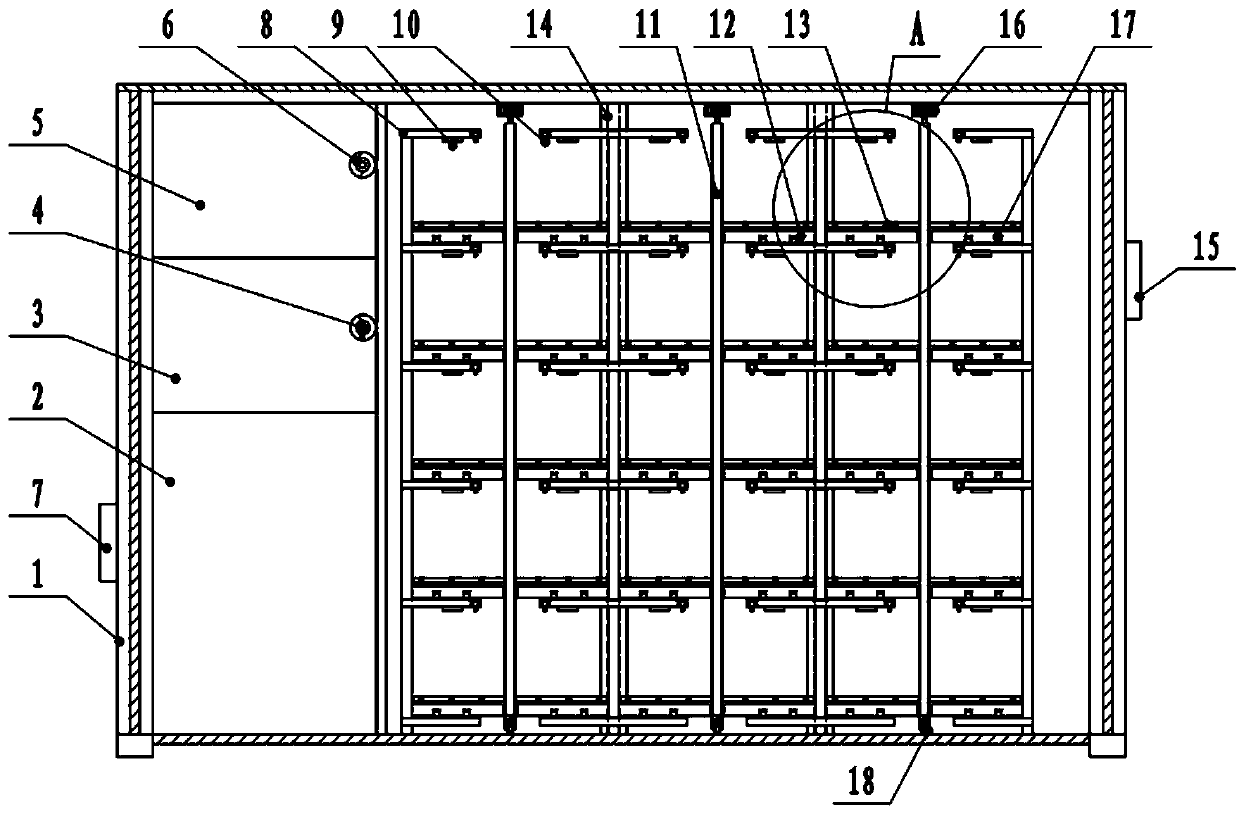

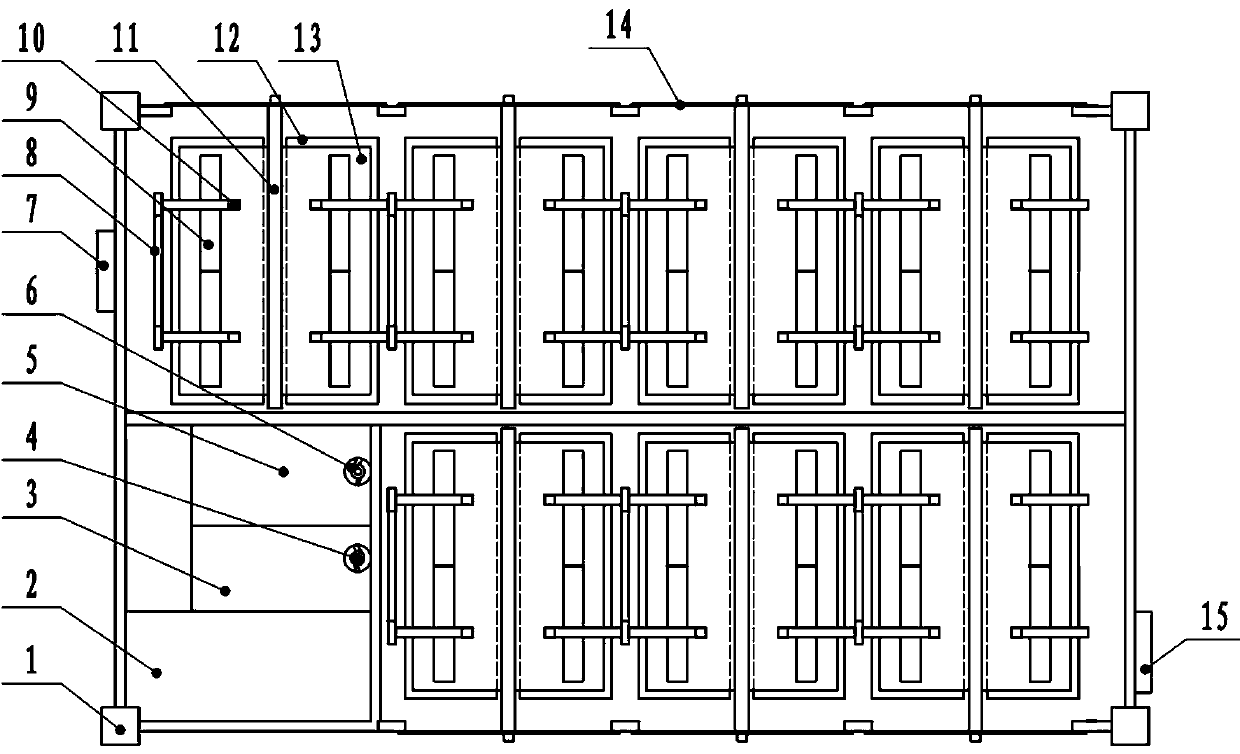

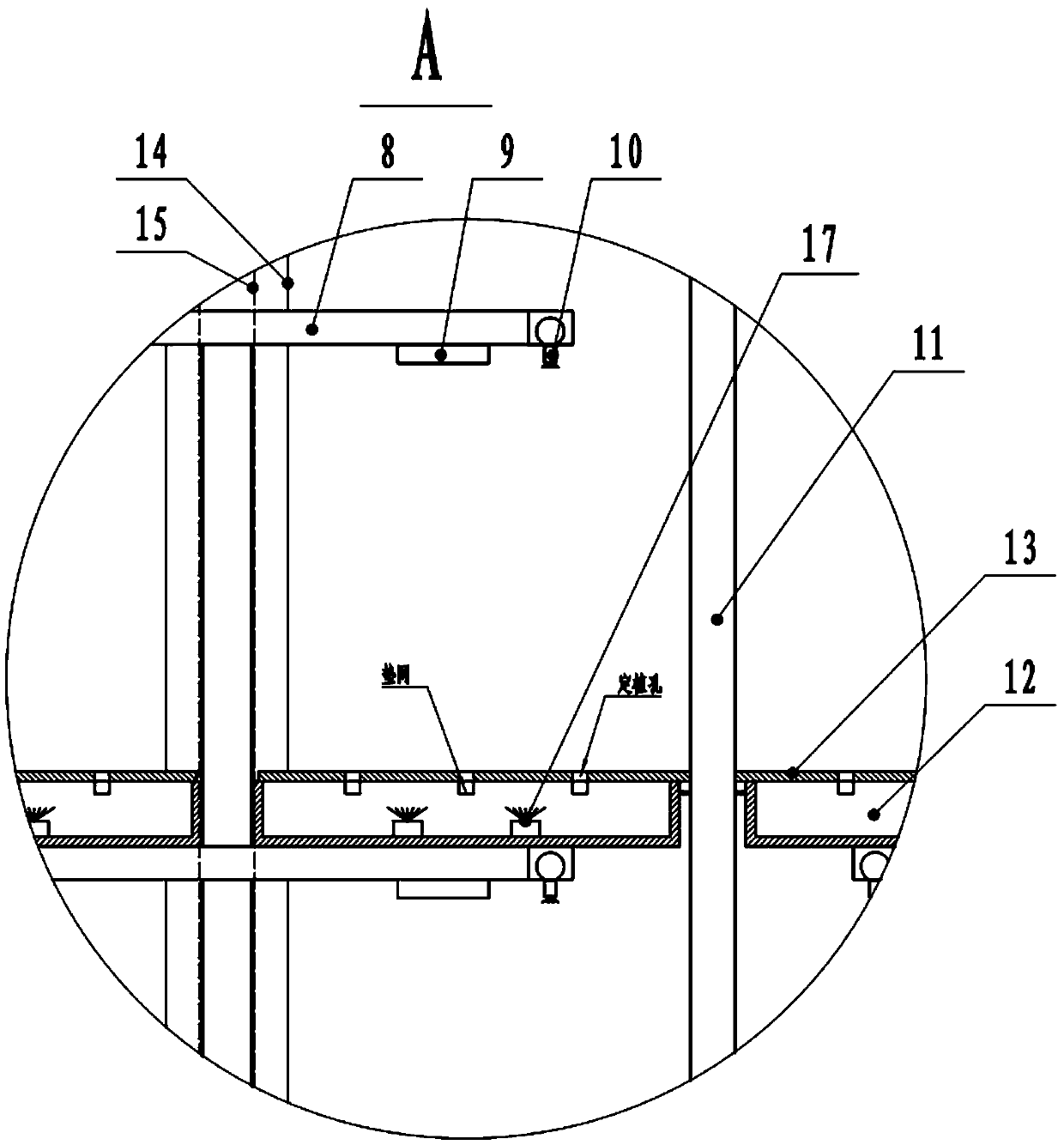

[0036] A container-type plant factory, which includes a container body 1 and a seedling tray frame 11. The container body 1 is placed on a horizontal plane, and its left, right, upper and bottom surfaces are respectively sealed by box plates; a plurality of seedling tray frames 11 are in the form of Two rows are distributed and installed in the container body 1; multi-layer seedling trays 13 are installed on the seedling tray frame 11; The upper end of 11 is connected with the upper slide rail of container body 1 top surface by pulley 16, and the lower end of seedling tray frame 11 is installed on the lower rail 18 of container body 1 bottom surface by lower pulley; Move out from the front and rear sides of container body 1 respectively; The top of seedling plate 13 is equipped with LED plant light source 9 and leaf surface water and fertilizer nozzle 10 by water and fertilizer tank frame 8, and the bottom of seedling plate 13 is installed with water and fertilizer tank 12 by w...

Embodiment 2

[0042] A container-type plant factory, which includes a container body 1 and a seedling tray frame 11, the container body 1 is placed on a horizontal plane, and its left, right, upper and bottom surfaces are respectively sealed by box plates; a plurality of seedling tray racks 11 are installed In the container body 1; multi-layer seedling tray 13 is installed on the seedling tray frame 11; the seedling tray 13 can be disassembled freely on the seedling tray frame 11; when the plants on the seedling tray 13 can be harvested, the seedling tray 13 is taken off , replace the new seedling tray 13; the seedling tray frame 11 is provided with a box surface 14 that can seal the seedling tray frame 11 in the container body 1; the box surface and the box plate are all made of heat-insulating materials; the seedling tray The upper end of frame 11 is connected with the upper slide rail of container body 1 top surface by pulley 16, and the lower end of seedling tray frame 11 is installed on...

Embodiment 3

[0049] A container-type plant factory, which includes a container body 1 and a seedling tray frame 11, the container body 1 is placed on a horizontal plane, and its left, right, upper and bottom surfaces are respectively sealed by box plates; a plurality of seedling tray racks 11 are installed In the container body 1; multi-layer seedling tray 13 is installed on the seedling tray frame 11; the seedling tray 13 can be disassembled freely on the seedling tray frame 11; when the plants on the seedling tray 13 can be harvested, the seedling tray 13 is taken off , change the seedling dish 13 of new kind; One side in the front and the back of container body 1 is also sealed by box plate, when the front of container body 1 was sealed with box plate, on the seedling plate frame 11 of corresponding box body rear, be installed with The seedling tray frame 11 is sealed on the box surface 14 in the container body 1, and the seedling tray frame 11 can be removed from the back of the contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com