A kind of preparation method of surgical drapes base material

A hole towel and cloth base technology, which is applied to the field of surgical hole cloth base material and its preparation, can solve problems such as poor antibacterial and mildew resistance, and achieve the effects of preventing bacterial penetration, reducing temperature difference, and solving low cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

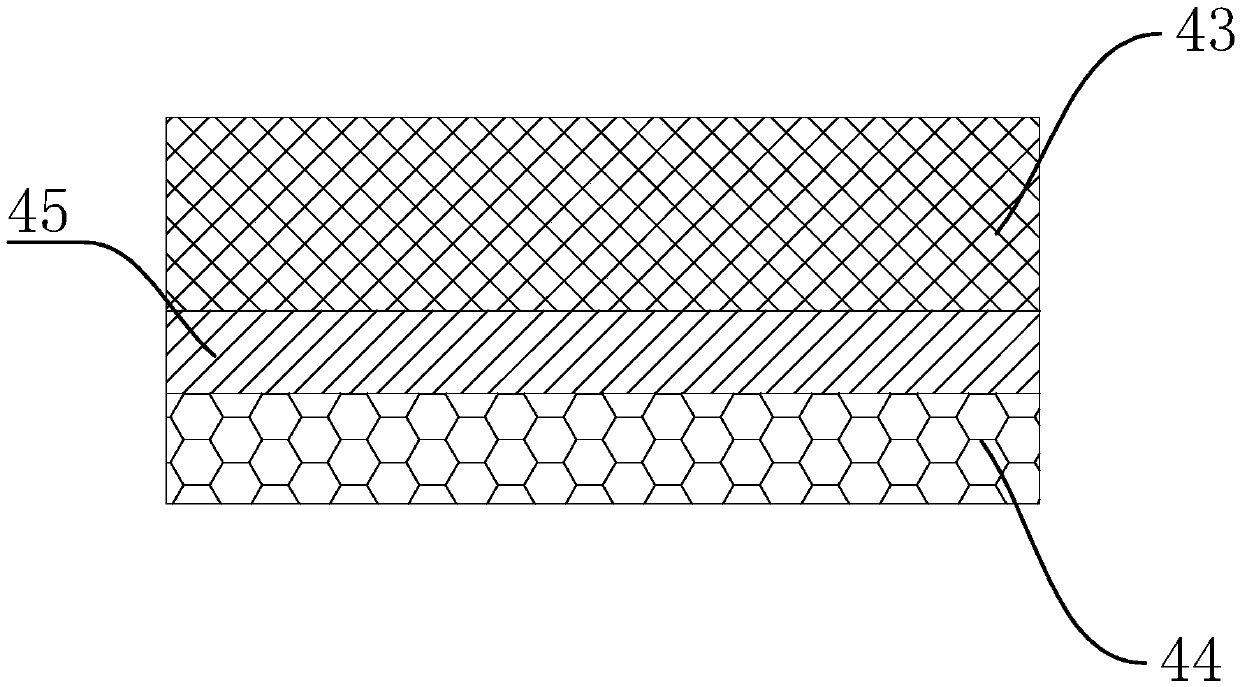

[0046] Such as figure 1 As shown, the present invention provides a surgical mask cloth substrate, including a non-woven fabric layer 43 and a film layer 44. The non-woven fabric layer 43 and the film layer 44 are bonded and combined by an adhesive layer 45. The non-woven fabric layer 43 is 45gsm white spunlace non-woven fabric, the adhesive layer 45 is 4gsm TEP903 glue, the film layer 44 is 25gsm polyethylene film, the components of the polyethylene film and their percentages are:

[0047] PE particles 7042 40%;

[0048] PE particles 7050 15%;

[0049] PE particles P01 30%;

[0050] Color additive B05 4%;

[0051] Color additive W01 1%;

[0052] Modified additive 2% (additive number is SHJ);

[0053] Anti-mildew and antibacterial additives 8% (additive number is MKJ1).

Embodiment 2

[0055] A surgical hole towel cloth substrate, comprising a non-woven fabric layer 43 and a film layer 44. The non-woven fabric layer 43 and the film layer 44 are bonded and combined by an adhesive layer 45. The non-woven fabric layer 43 is a 50gsm white spunlace nonwoven Cloth, the adhesive layer 45 is 3.0gsm TEP903 series glue, the film layer 44 is 20gsm polyethylene film, the components of the polyethylene film and their content percentages are:

[0056] PE particles 7042 30%;

[0057] PE particles 7050 20%;

[0058] PE particles P01 35%;

[0059] Color additive B05 5%;

[0060] Color additive W01 2%;

[0061] Modified additive 2% (additive number is SHJ);

[0062] Anti-mildew and antibacterial additive 6% (additive number is MKJ1).

Embodiment 3

[0064] A surgical mask cloth substrate, comprising a non-woven fabric layer 43 and a film layer 44. The non-woven fabric layer 43 and the film layer 44 are bonded and compounded by an adhesive layer 45. The non-woven fabric layer 43 is a 50gsm blue SMS non-woven Cloth, the adhesive layer 45 is 3gsm TEP903 series glue, the film layer 44 is a 20gsm polyethylene film, the components of the polyethylene film and their content percentages are:

[0065] PE particles 7042 32%;

[0066] PE particles 7050 16%;

[0067] PE particles P01 33%;

[0068] Color additive B05 3%;

[0069] Color additive W01 3%;

[0070] Modified additive 3% (additive number is SHJ);

[0071] Anti-mildew and antibacterial additive 10% (additive number is MKJ1).

[0072] The main physical parameters of the surgical hole towel cloth substrate of the present invention are width, grammage, tensile strength, peeling strength and water pressure resistance. The equipment used for the weight test is a specific gravity balance fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| winding tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

| winding tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com