Hot melt adhesive modified asphalt

A technology for modifying asphalt and hot-melt adhesives, which is applied in building components, building insulation materials, construction, etc., can solve the problems of high carcinogenic asphalt smoke and high energy consumption, and achieve the effect of less energy and good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

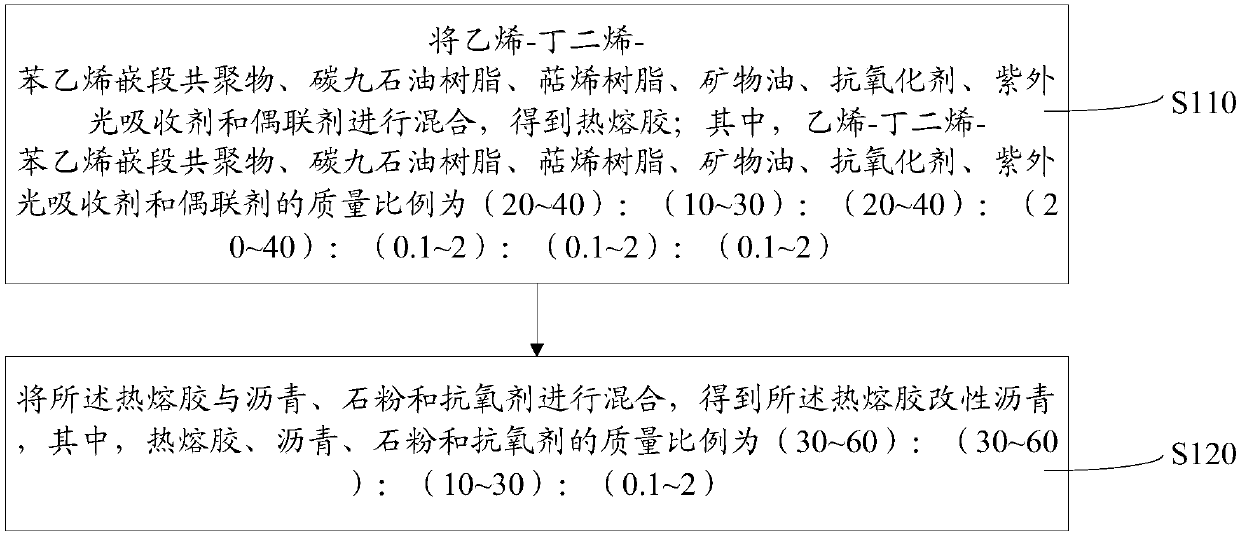

[0027] see figure 1 , the preparation method of hot melt adhesive modified asphalt in one embodiment, comprises the steps:

[0028]S110: Mix ethylene-butadiene-styrene block copolymer, C9 petroleum resin, terpene resin, mineral oil, antioxidant, ultraviolet absorber and coupling agent to obtain hot melt adhesive; wherein, ethylene -The mass ratio of butadiene-styrene block copolymer, C9 petroleum resin, terpene resin, mineral oil, antioxidant, ultraviolet absorber and coupling agent is (20~40): (10~30) :(20~40):(20~40):(0.1~2):(0.1~2):(0.1~2).

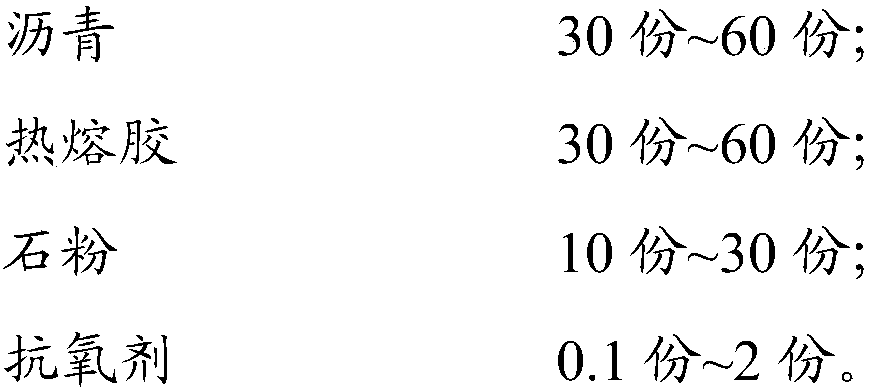

[0029] S120: Mix the hot melt adhesive with asphalt, stone powder and antioxidant to obtain the hot melt adhesive modified asphalt, wherein the mass ratio of hot melt adhesive, asphalt, stone powder and antioxidant is (30-60 ): (30~60): (10~30): (0.1~2).

[0030] In order to further enhance the comprehensive performance of the hot-melt adhesive modified asphalt, for example, the hot-melt adhesive modified asphalt also includes a rei...

Embodiment 1

[0035] Ethylene-butadiene-styrene block copolymer 1kg, C9 petroleum resin 0.6kg, terpene resin 1.1kg, mineral oil 1.2kg, antioxidant 0.06kg, ultraviolet absorber 0.08kg and coupling agent 0.1kg Heat and mix in the reactor to obtain hot melt adhesive.

[0036] 4.5 kg of the hot melt adhesive, 4.4 kg of asphalt, 5.4 kg of stone powder and 0.05 kg of antioxidant were mixed to obtain the hot melt adhesive modified asphalt.

Embodiment 2

[0038] With ethylene-butadiene-styrene block copolymer 1.5kg, C9 petroleum resin 0.7kg, terpene resin 1.1kg, mineral oil 1.2kg, antioxidant 0.06kg, ultraviolet absorber 0.08kg and coupling agent 0.1 kg is heated and mixed in the reactor to obtain hot melt adhesive.

[0039] 5.2 kg of the hot melt adhesive, 4.4 kg of asphalt, 5.4 kg of stone powder and 0.05 kg of antioxidant were mixed to obtain the hot melt adhesive modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com