Technological method for improving strength of preheated pellets in grate-rotary kiln

A process method and rotary kiln technology, which is applied in the field of grate machine and rotary kiln, can solve problems such as easy ring formation, and achieve considerable technical and economic indicators and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

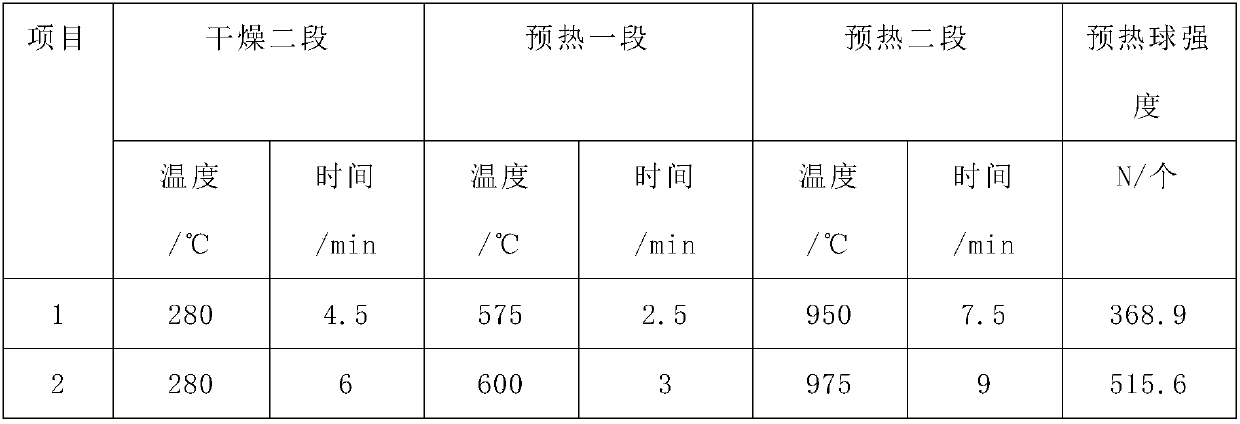

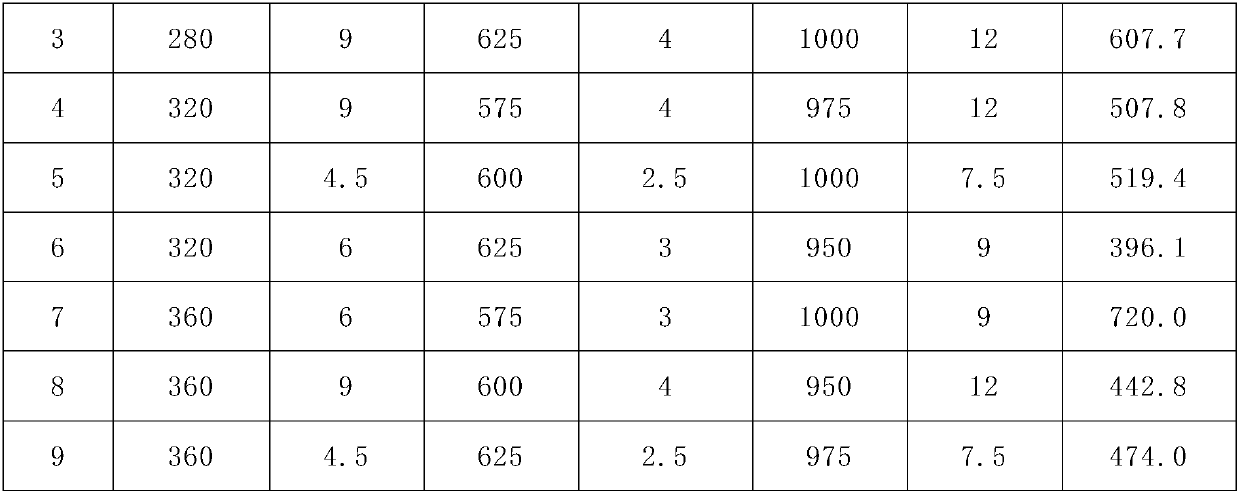

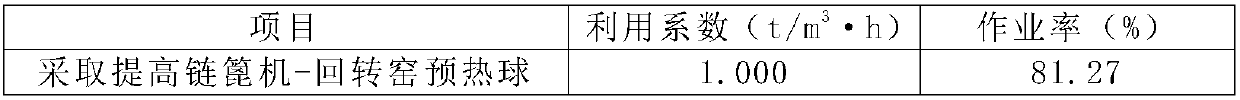

[0022] Starting from the actual production, this process method is fully applied to the 1.2 million tons of grate machine-rotary kiln pellet production process in the west area of Baotou Steel. Compared with the process before adopting the process method, it mainly has the following effects. As shown in Table 1, different process systems are designed for orthogonal experiments. Lower chain grate - rotary kiln preheating ball strength.

[0023] Table 1 The quality of the preheating ball in different process systems of the chain grate

[0024]

[0025]

[0026] Note: The temperature of the first stage of drying is 230°C. When the machine speed is 2.4m / min, 2m / min, and 1.5m / min, the preheating time of the first stage is 2.5min, 3min, and 4min.

[0027] The best process conditions can be obtained through the orthogonal experiment range and variance analysis: the temperature of the second stage of drying is 360°C, and the time is 6 minutes; the temperature of the first stag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com