High performance double charge perforating charge

A perforating bullet and high-performance technology, which can be used in wellbore/well components, production fluid, earthwork drilling and mining, etc., and can solve problems such as defects in explosive energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

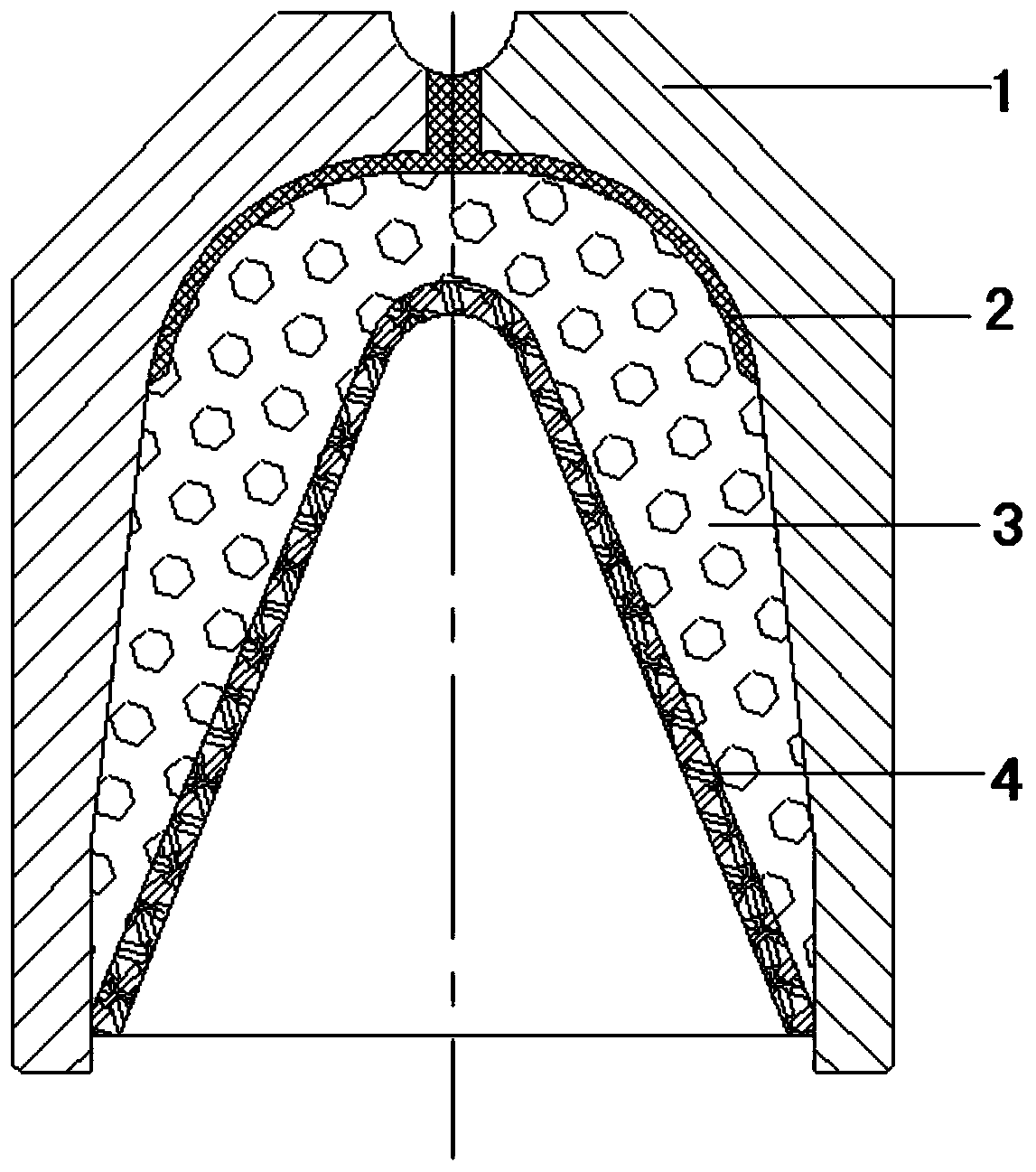

Embodiment 1

[0043] Such as figure 1 As shown, the explosive is composed of auxiliary explosive HMX and main explosive HNS. The auxiliary explosive HMX has a mass of 4g and a layer thickness of 2mm. The auxiliary explosive is distributed in the hemispherical cavity of the shell; It is 34g. The maximum head velocity of the double-charge perforating bullet jet is: 6411m / s, which is 8.3% higher than the original design; the maximum kinetic energy of the double-charge perforating bullet cover is 2.6×10 10 µj; 11.4% higher than the original design.

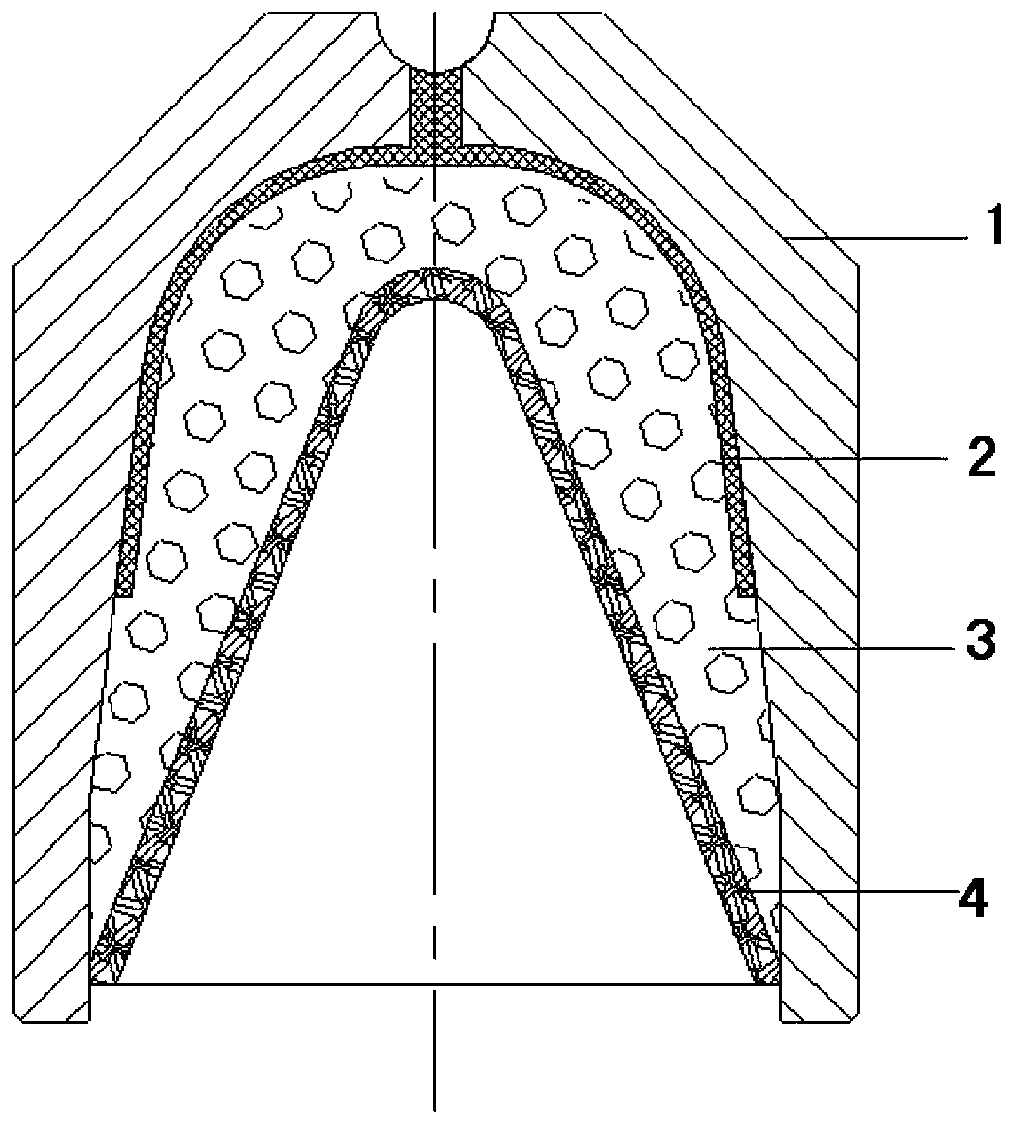

Embodiment 2

[0045] Such as figure 2 As shown, the explosive is composed of auxiliary explosive HMX and main explosive HNS. The auxiliary explosive HMX has a mass of 6g and a layer thickness of 2mm. HNS mass is 32g. The maximum head velocity of the double-charge perforating bullet jet is: 7092m / s, which is 19.9% higher than the original design; the maximum kinetic energy of the double-charge perforating bullet cover is 3.22×10 10 µj; 37.8% higher than the original design.

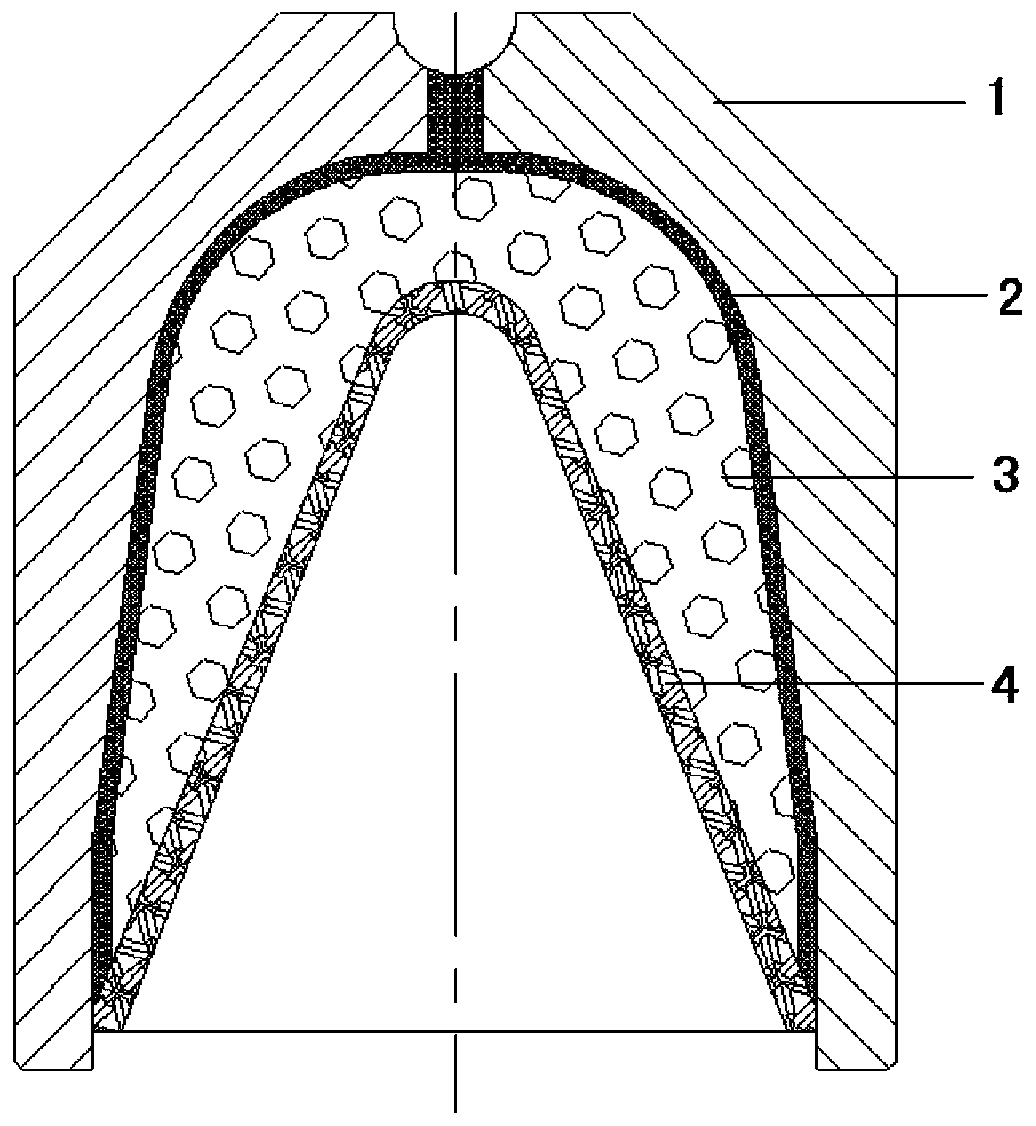

Embodiment 3

[0047] Such as image 3 As shown, the explosive is composed of auxiliary explosive HMX and main explosive HNS. The auxiliary explosive HMX has a mass of 8g and a layer thickness of 2mm. HNS mass is 30g. The maximum head velocity of the double-charge perforating bullet jet is: 7143m / s, which is 20.8% higher than the original design; the maximum kinetic energy of the double-charge perforating bullet cover is 3.65×10 10 µj; 56.5% higher than the original design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com