Self-adaptive torsional vibration damper and diesel engine

A torsional vibration damper, self-adaptive technology, applied in the direction of spring/shock absorber, mechanical equipment, vibration suppression adjustment, etc., can solve the problems that affect the service life of the device, complex structure, heat generation of the unit, etc., to achieve installation and fixation Convenience, safe operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

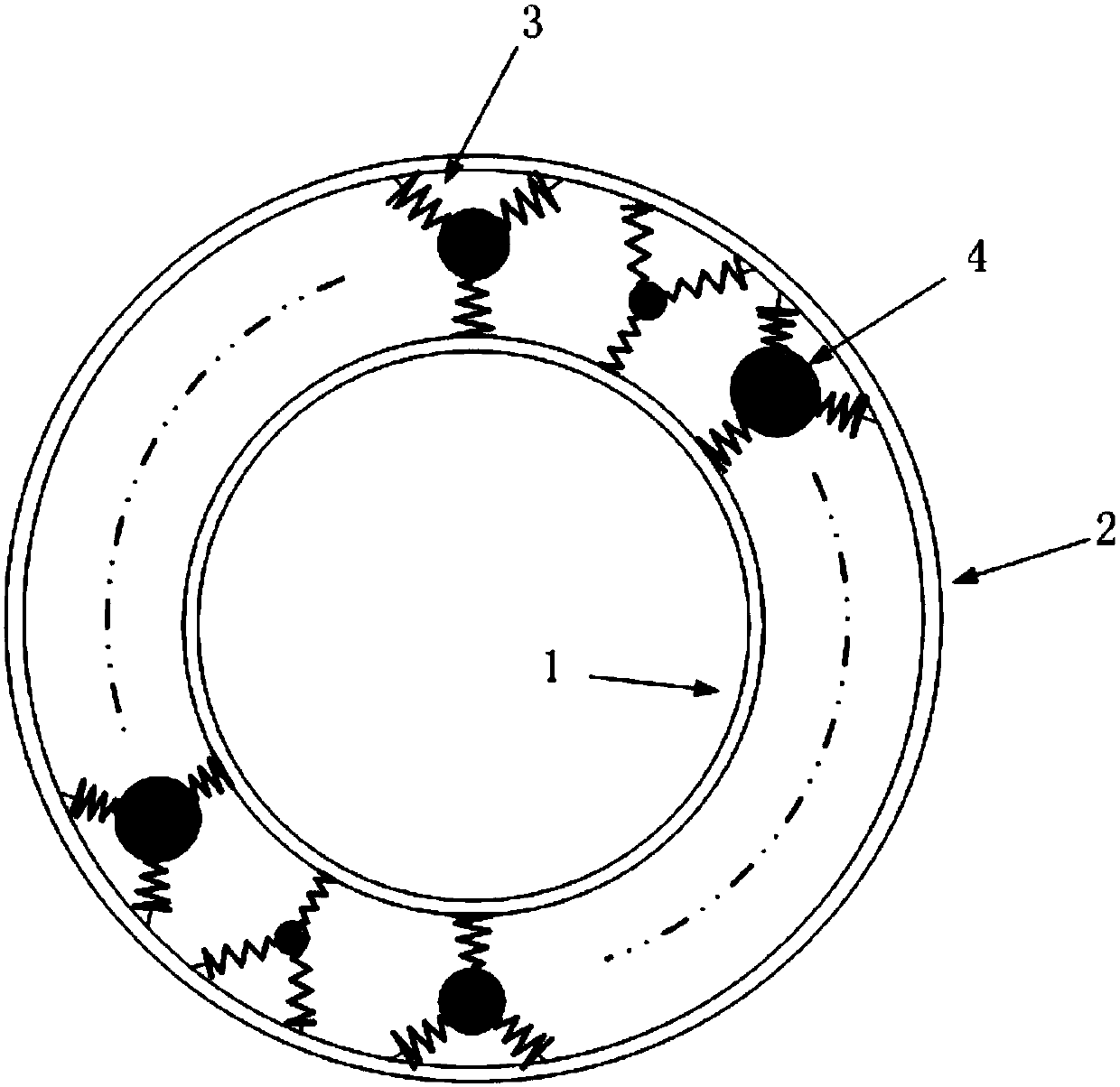

[0025] As mentioned in the background technology section, most of the torsional vibration absorbers currently used are damping type, which have complex structures and high costs. During the energy conversion process, the unit is likely to generate heat, which affects the service life of the device.

[0026] Aiming at the deficiencies in the prior art, the present invention provides an adaptive torsional vibration damper. When the excitation force frequency of the rotating shaft coincides with the resonance frequency, the torsional vibration energy at the frequency is absorbed by setting the resonator in a targeted manner. With vibration reduction, the torsional vibration amplitude can be reduced from the source point of view to ensure the safe operation of the shaft system.

[0027] The technical solutions of the present invention will be clearly and completely described below through specific embodiments. Apparently, the described embodiments are only some of the embodiments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com