An electrochemical working electrode for sensing tyrosine

A sensing electrode, electrochemical technology, applied in scientific instruments, material analysis by electromagnetic means, instruments, etc., can solve the problems of low sensitivity, narrow linear range, and high preparation cost, and achieve high sensitivity, wide linear range, and preparation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

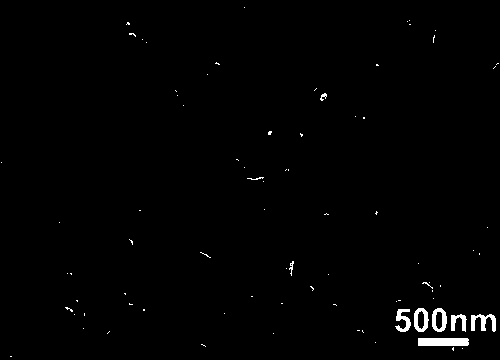

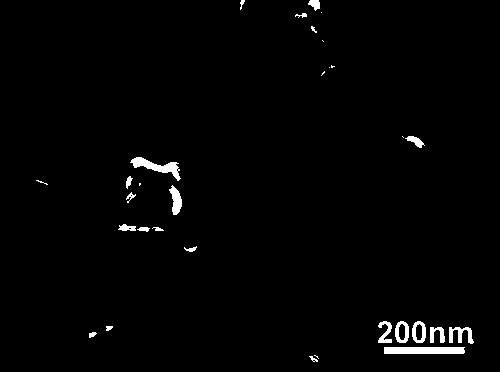

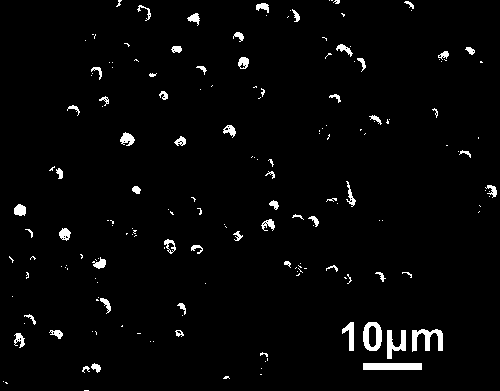

[0021] Specific embodiment one: This embodiment is a kind of electrochemical working electrode that is used for sensing tyrosine to be by ITO electrode and the carbon nanotube / chitosan- The composite film of copper chelate is composed of a polyethyleneimine layer, a phosphomolybdovanadium heteropolyacid-doped multi-walled carbon nanotube layer, and a chitosan-copper chelate layer from the ITO electrode layer to the outside. The carbon nanotube layer doped with phosphomolybdovanadium heteropolyacid and the chitosan-copper chelate layer are one cycle, and the cycle is n times, marked as PEI / [P 2 Mo 16 V 2 -MWCNTs / CTS-Cu] n .

specific Embodiment approach 2

[0022] Embodiment 2: A preparation method of an electrochemical working electrode for sensing tyrosine is carried out in the following steps.

[0023] 1. Preparation of carbon nanotube solution doped with phosphorus molybdenum vanadium heteropolyacid:

[0024] ① Dissolve multi-walled carbon nanotubes in deionized water under ultrasonic stirring at a frequency of 80Hz-100Hz, and continue ultrasonication for 10h-12h to obtain solution A;

[0025] ②Under the condition of magnetic stirring with a stirring speed of 40r / min~60r / min, the Dawson type polyoxometalate P 2 Mo 16 V 2 Dissolve in deionized water, and continue to stir for 5 to 10 minutes to obtain solution B;

[0026] ③ Add solution B dropwise to solution A at a rate of 5 mg / s to 10 mg / s, and ultrasonically stir for 12 hours to 24 hours at a temperature of 25 to 40 °C, with an ultrasonic frequency of 80 Hz to 100 Hz, to obtain phosphomolybdenum vanadium Polyacid-doped carbon nanotube solution, denoted as P 2 Mo 16 V ...

specific Embodiment approach 3

[0057] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that the ratio of the mass of multi-walled carbon nanotubes to the volume of deionized water in solution A in step ① is 30 mg:10 mL. Other steps and parameters are the same as those in the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com