Calculation method for simulating impact effects caused to molten pools by molten drops in laser arc hybrid welding

A hybrid welding and laser arc technology, which is applied in laser welding equipment, computing, welding equipment, etc., can solve the problems of low accuracy in calculating short-circuit transition and jet transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

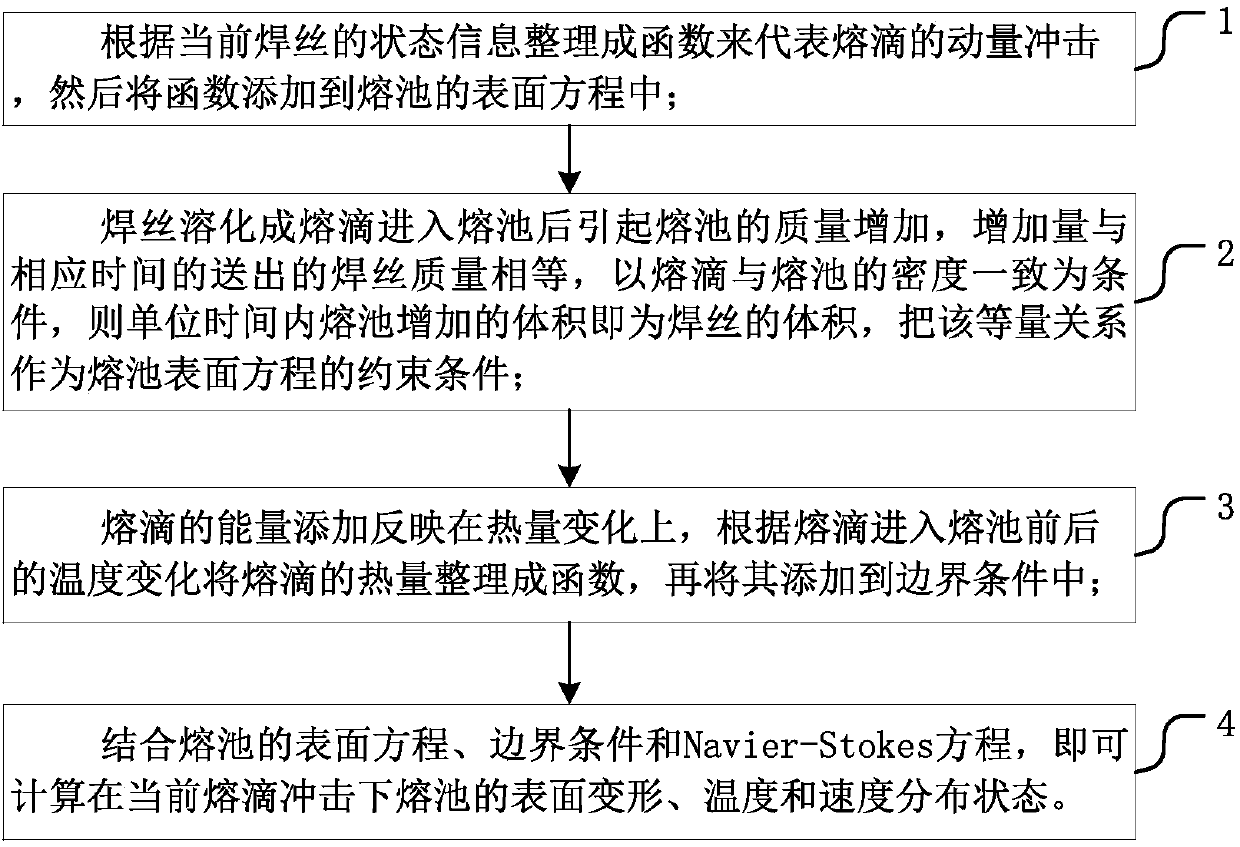

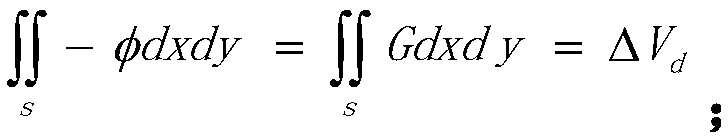

[0041] like figure 1 As shown, the calculation method for simulating the impact of droplets on the molten pool in hybrid laser arc welding in an embodiment of the present invention is characterized in that the impact of droplets on the molten pool is divided into three types: momentum impact, mass addition and energy addition. Aspects, and then sorted into corresponding mathematical functions for calculation, and finally obtained the surface deformation, temperature and velocity distribution of the molten pool under the impact of the droplet, the processing steps are as follows:

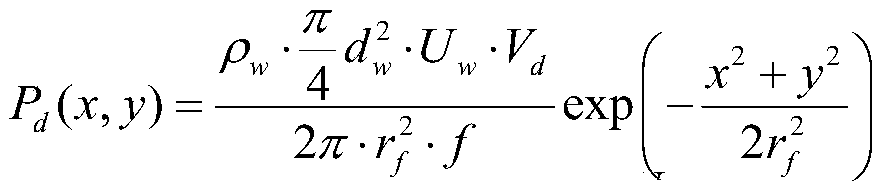

[0042] Step 1. According to the state information of the current welding wire, organize it into a function P d (x,y) to represent the momentum impact of the droplet, and then the function P d (x,y) is added to the surface equation of the melt pool.

[0043] where the function P d (x,y) can be obtained as follows:

[0044] Step 11, set the volume of the welding torch wire feeding per unit time as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com