Heat-resistant resin composition and its production method

A technology of heat-resistant resin and composition, which is applied in the field of heat-resistant resin composition, can solve problems such as insufficient heat resistance, and achieve the effect of excellent heat resistance and excellent balance of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

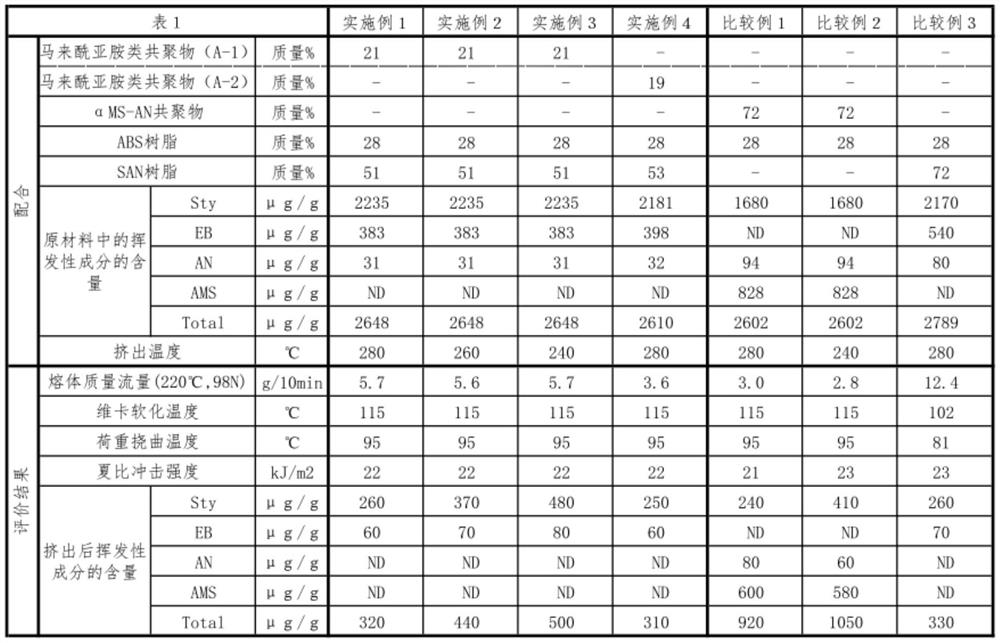

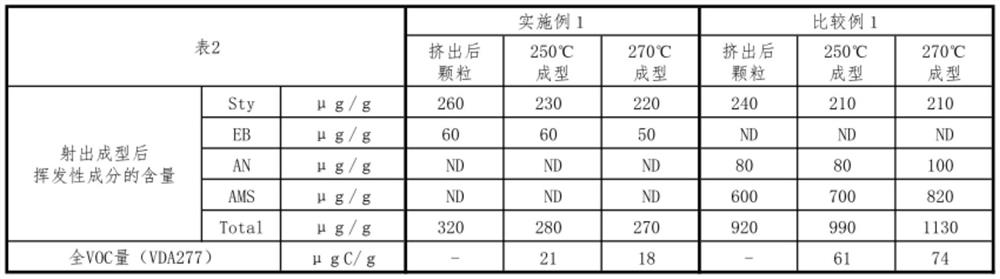

Embodiment 1~4、 comparative example 1~3

[0099] The maleimide copolymer, ABS resin, SAN resin, and α-methylstyrene acrylonitrile copolymer were mixed as shown in Table 1, melted, kneaded, and devolatilized by an extruder to obtain a resin composition. As the extruder, a twin-screw extruder (35B, TE-ma, manufactured by Toshiba Machine Co., Ltd.) was used. As a configuration of the extruder, first, a kneading section for melt-kneading the respective resins was installed, then a kneading section for adding water and kneading was installed, and then a devolatilization section was installed. The extrusion temperature (the temperature of the filling cylinder in the kneading section and the devolatilization section) is set to the set temperature shown in Table 1, the screw speed is 250rpm, and the feed rate is 30kg / hr for extrusion. Water was added so that it might become 0.5 mass % with respect to the feed amount, and the pressure of a devolatilization part was set to 10 mmHg. The obtained resin composition was evaluated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com