Method and device for measuring contact force of pantograph and catenary

A measurement method and a technology of a measurement device, which are applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problems of complex experimental devices and many installation restrictions, and achieve good anti-interference and measurement The effect of small error and simple installation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

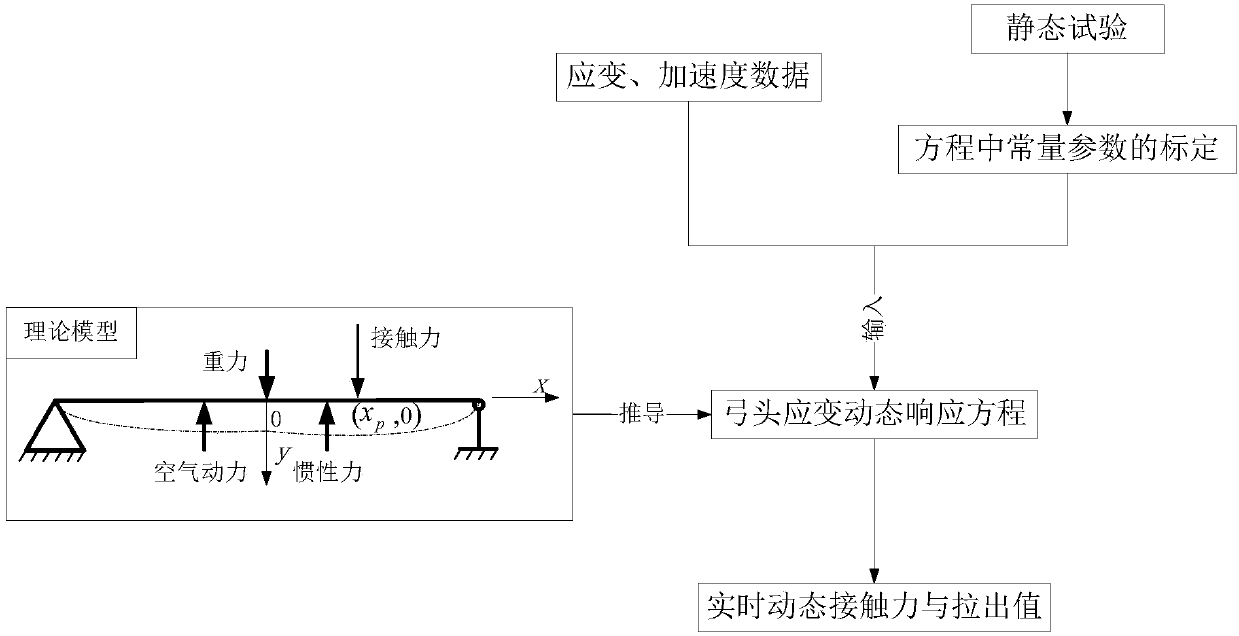

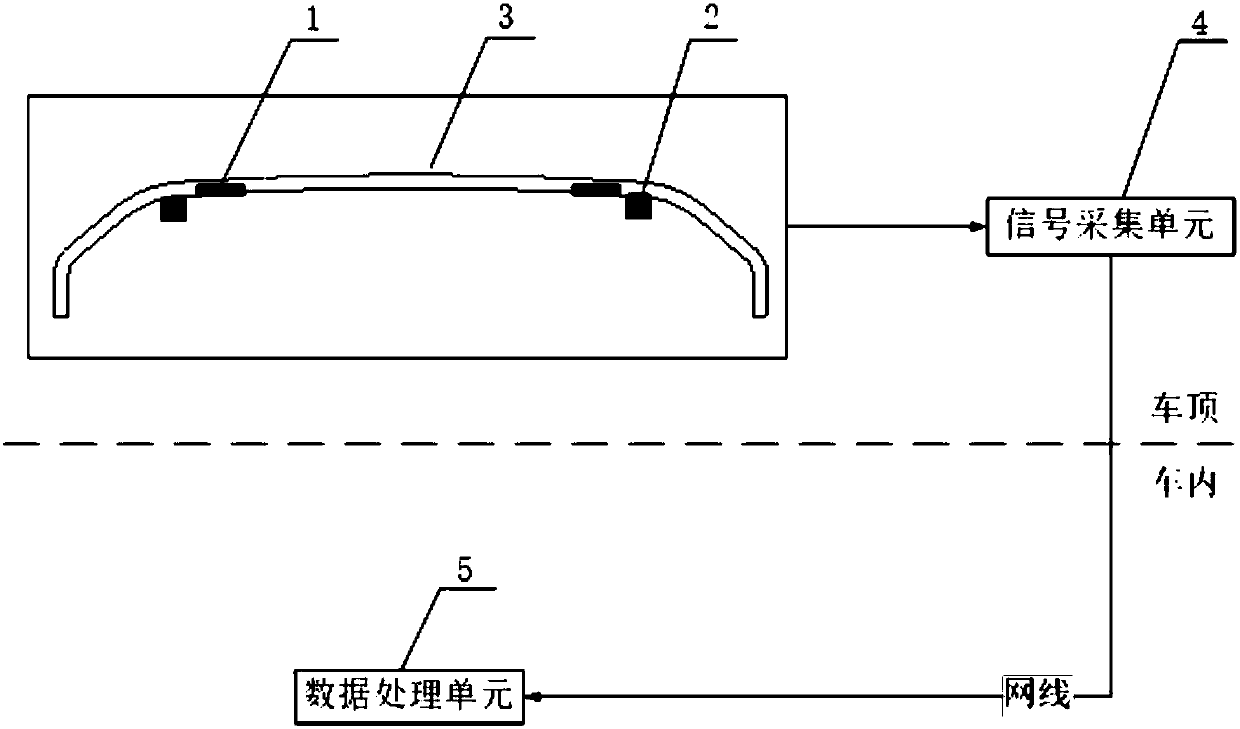

[0028] now attached figure 1 The present invention is further described.

[0029] A pantograph-catenary contact force measurement method is to regard the pantograph head as a beam model, and derive the dynamic response equation of the bow head strain,

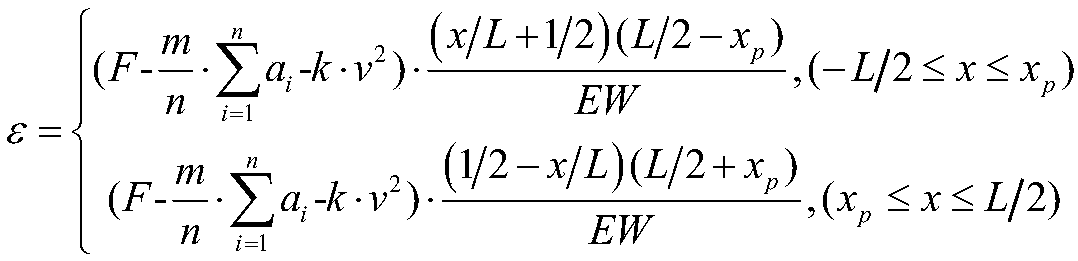

[0030] The bow head strain dynamic response equation is as follows:

[0031]

[0032] In the formula: ε is the longitudinal strain of the pantograph slide, which is measured by the strain sensor; F is the contact force between the pantograph and the catenary; m is the sprung mass of the bow head. In this embodiment, the TSG22 pantograph is used, and m=4.8 kg; a i Is the acceleration of the ith acceleration sensor at the bottom of the slide plate, which is measured by the acceleration sensor; n is the number of acceleration sensors, and in this embodiment n=2; k is the aerodynamic proportional coefficient, where k=0.00228; v is the train running speed, x p is the abscissa of the position of the contact point; x is the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com