Chuck, stepped jaw, and machine tool

A chuck and claw technology, applied in the field of chuck mechanism, can solve problems such as processing obstacles, efficiency reduction, and complicated operations, and achieve the effect of low possibility, high efficiency, and rapid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

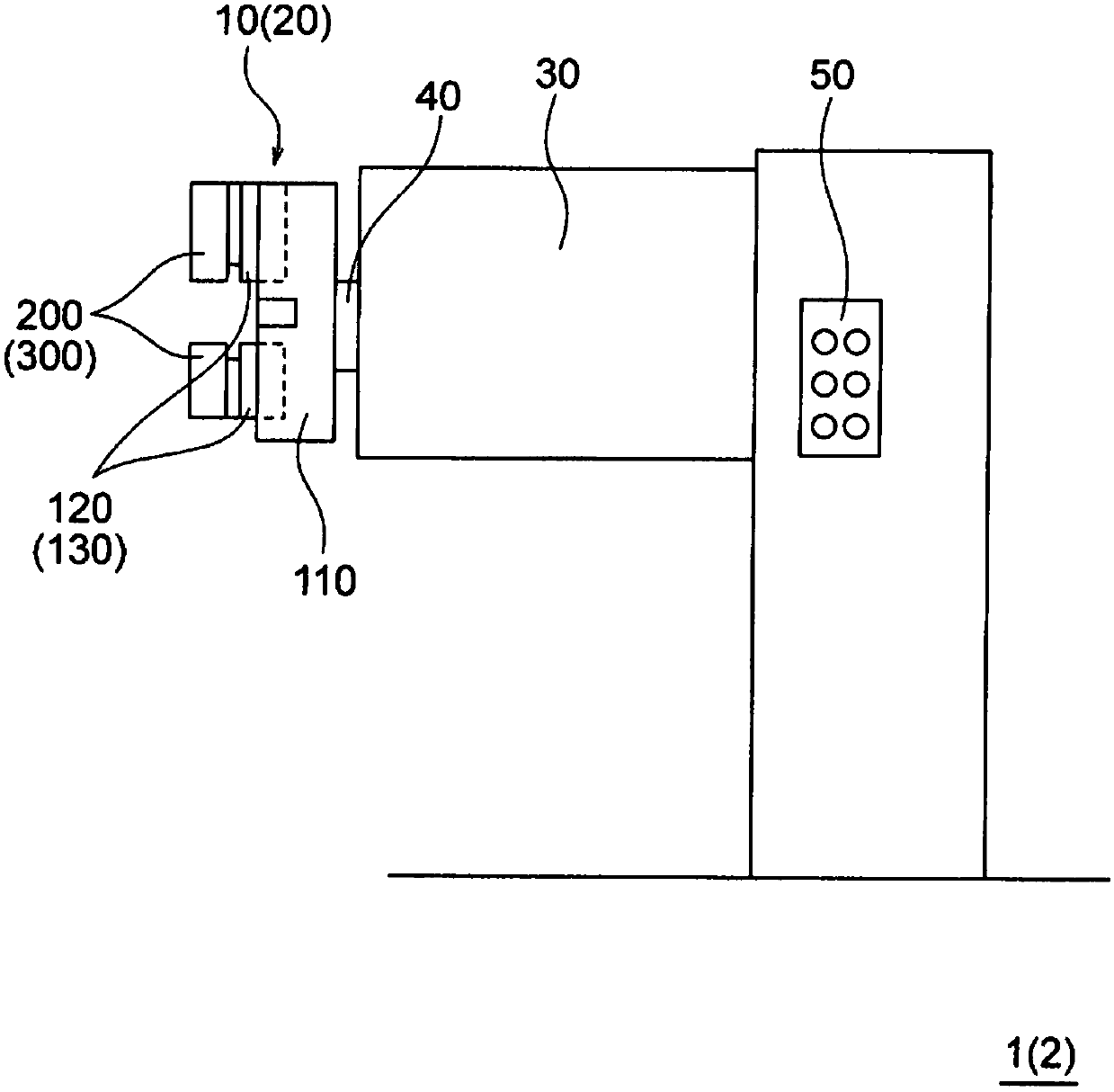

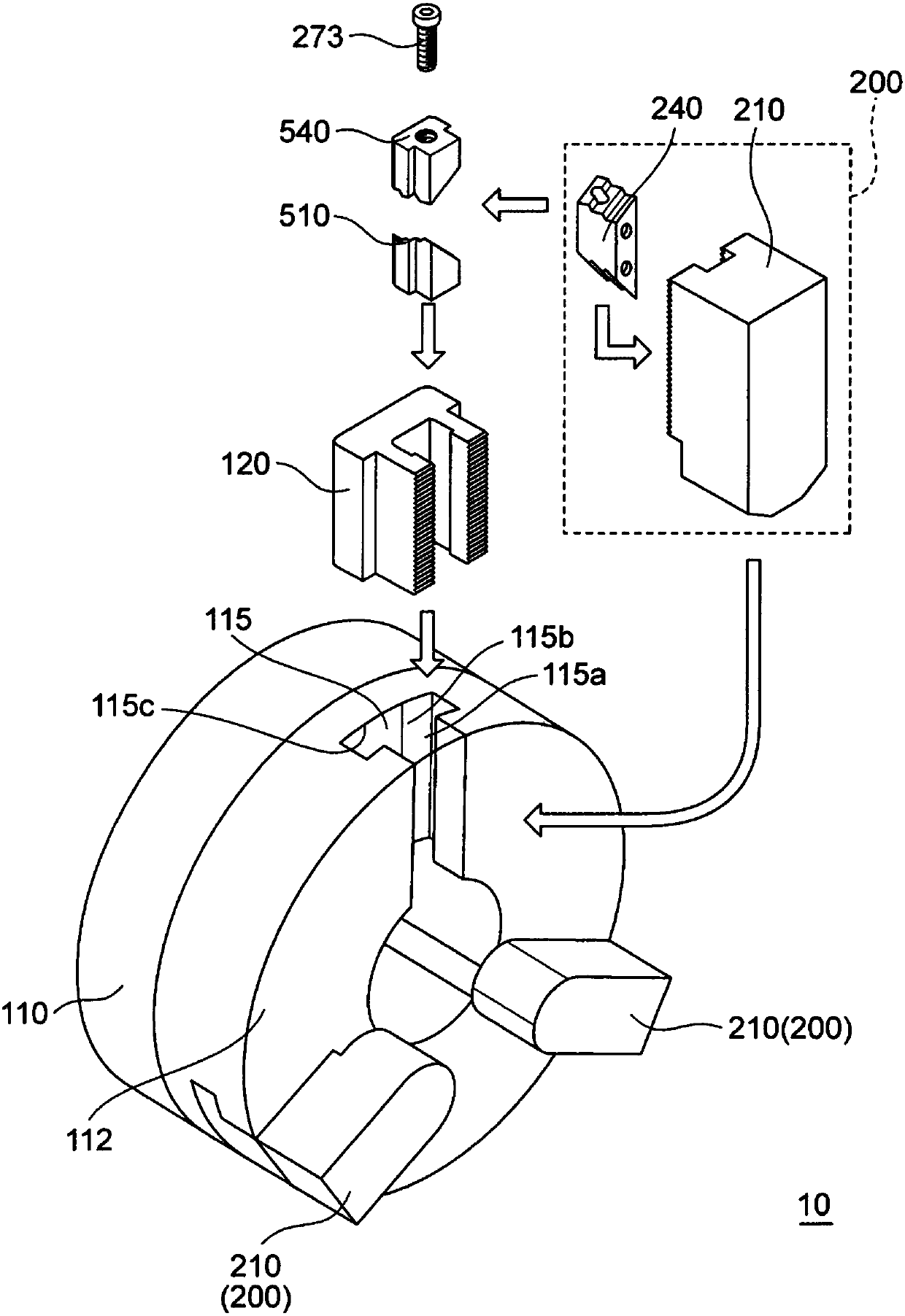

[0043] refer to Figure 1 ~ Figure 1 3. Describe the first embodiment of the present invention. In this embodiment, a lathe to which the guide jaw and chuck mechanism of the present invention is applied will be described as an example of the machine tool of the present invention. In addition, in the description of each of the following embodiments including the first embodiment, the same reference numerals are assigned to the same or similar configurations, and descriptions repeated in each embodiment will be omitted. Such as figure 1 As shown, the lathe 1 of this embodiment has: a chuck mechanism 10 for gripping a workpiece to be processed; a motor 30 for rotationally driving the chuck mechanism 10; and a control unit 50 for controlling the transmission of the rotational power of the motor 30 to the chuck. The spindle (spindle) 40 of the disk mechanism 10, the motor 30, and the like.

[0044] Such as figure 2 As shown, the chuck mechanism 10 has a cylindrical chuck body ...

no. 2 approach

[0093] main reference Figure 14 ~ Figure 17B , to describe the second embodiment of the present invention. The lathe 2 of the second embodiment (refer to figure 1 ) means that the structure of the main jaw, guide jaws, and clamps of the chuck mechanism 20 is different from that of the chuck mechanism 10 of the lathe 1 of the first embodiment.

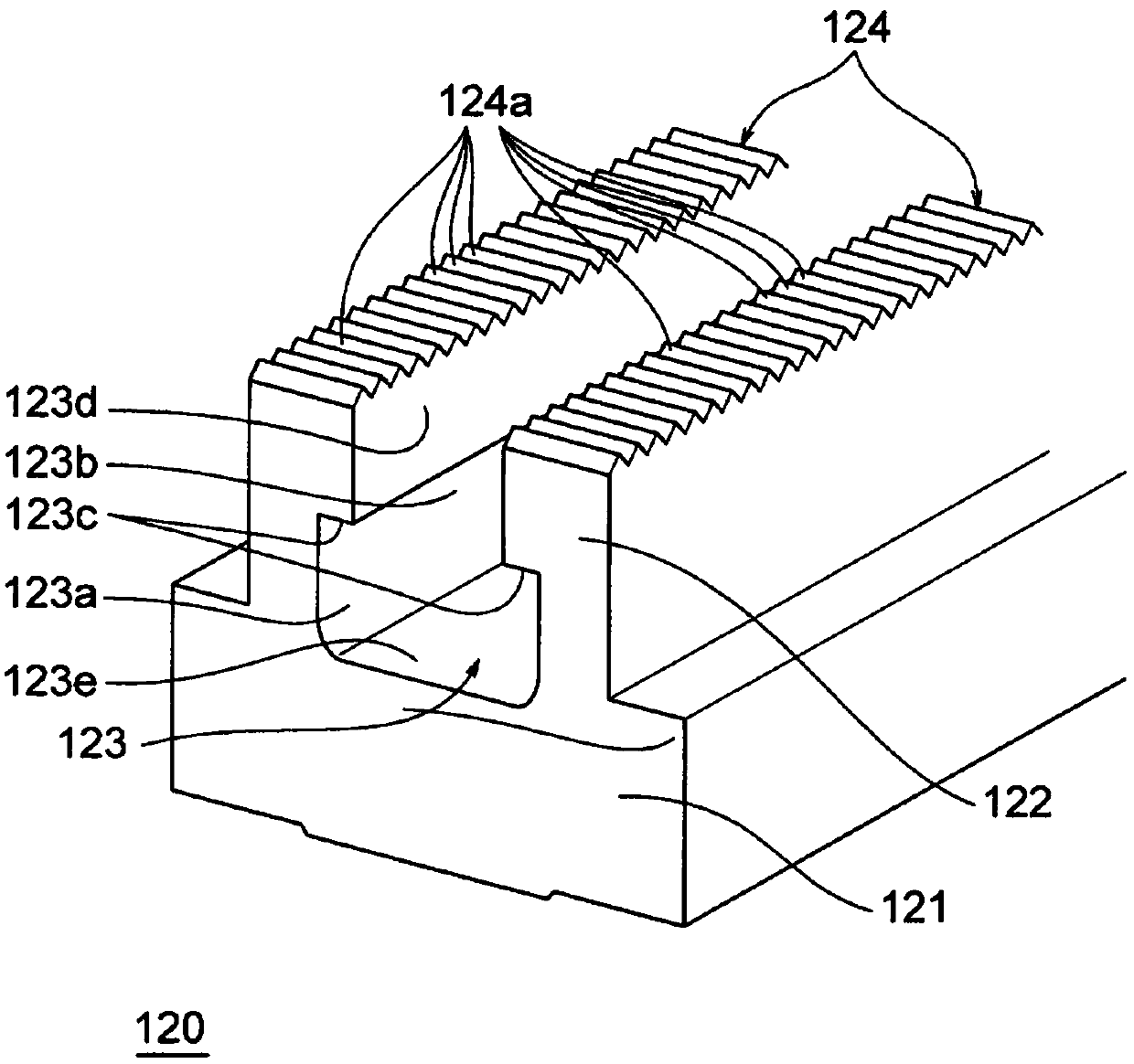

[0094] Such as Figure 14 As shown, the main jaw 130 is different from the main jaw 120 of the first embodiment in the structure of the serrated surface 134 on both sides of the claw setting groove 123 . Such as Figure 14 As shown, the sawtooth pattern formed on the sawtooth surface 134 of the main jaw 130 is a structure in which a plurality of square tapered spikes 134a are arranged. The cross-sectional shape of each spike 134a is substantially triangular, and each spike 134a has a chamfered front end and four slopes inclined from the front end.

[0095] The spikes 134a are arranged at predetermined intervals in the extending di...

no. 3 approach

[0114] refer to Figure 18A ~ Figure 19C , the third embodiment of the present invention will be described. Such as Figure 18A , Figure 18B As shown, in the guide claws 200b, 300b of the third embodiment, the U-shaped grooves 265, 365 opened at the bottom are formed in the guides 240b, 340b instead of fastening bolt passing holes. Figure 18A It is a guide claw 200b showing a third embodiment in which a fastening bolt passing U-shaped groove 365 is formed in a guide 240 with respect to the guide claw 200 of the first embodiment, Figure 18B It shows the guide claw 300b of the third embodiment in which the U-shaped groove 365 for fastening bolt passing is formed in the guide 340 with respect to the guide claw 300 of the second embodiment.

[0115] The guide claws 200 and 300 of the above-mentioned first and second embodiments pass the fastening bolts 273 through the fastening bolt passing holes 263 and 363 formed in the guides 240 and 340, and hold the guides 240 and 340 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com