Production method for intelligent transmitting device

A production method and intelligent technology, applied in the direction of cleaning methods using tools, auxiliary devices, measuring devices, etc., can solve the problems of inability to carry out mass production, low production efficiency, and no production method for power transmitters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

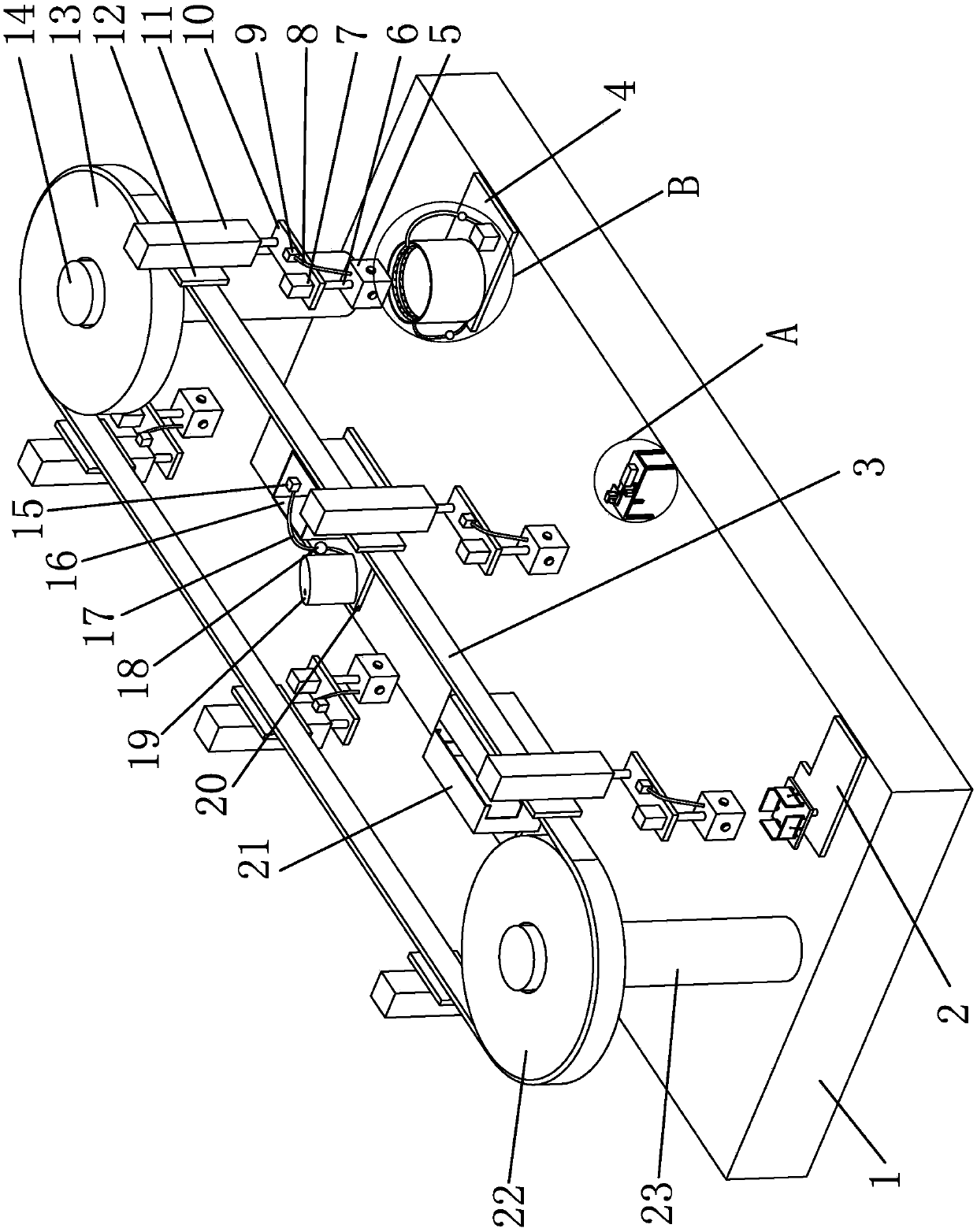

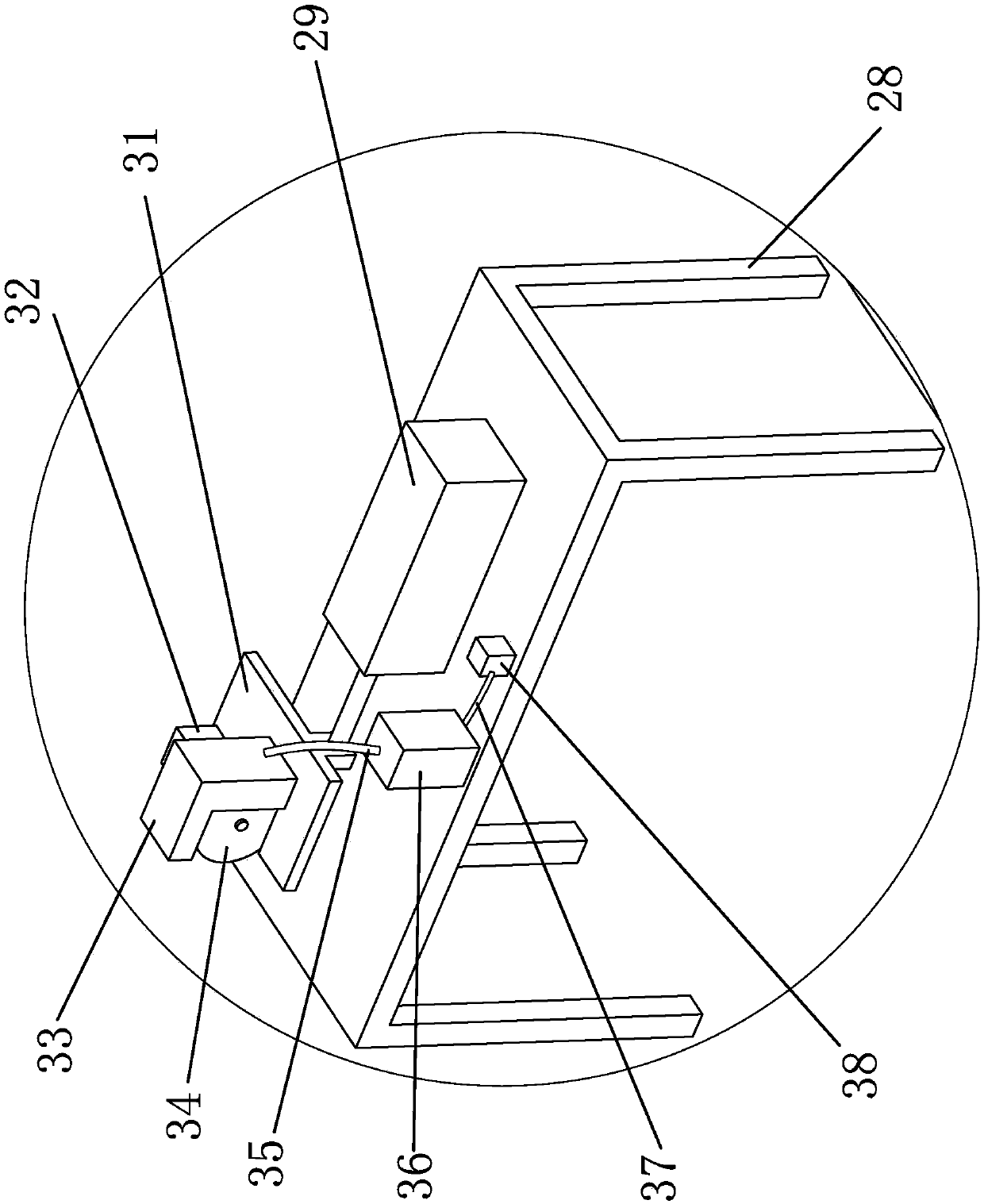

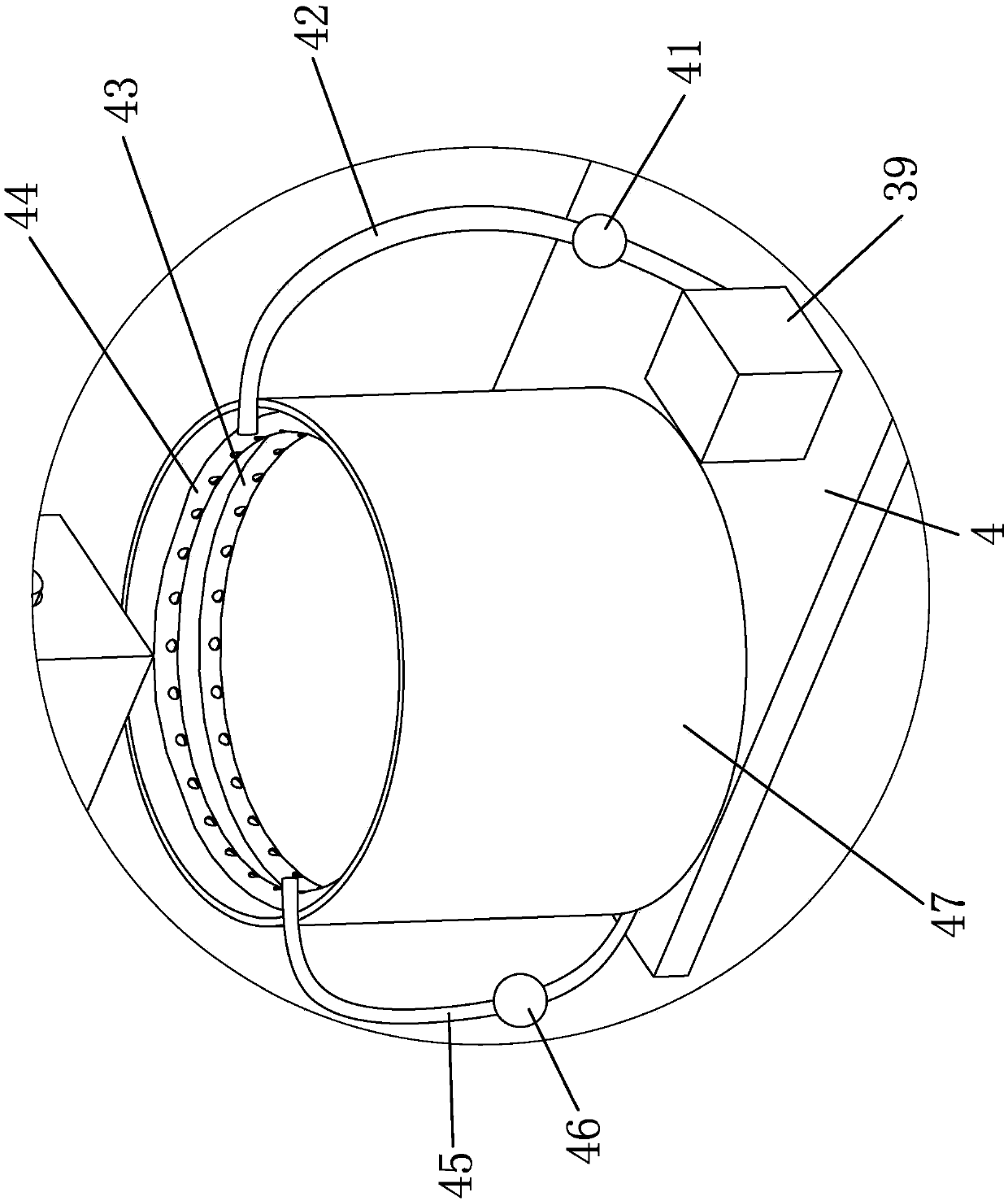

[0055] The production method of the intelligent transmission device, the intelligent transmission device includes a front cover, a box body, a rear cover, a liquid crystal display, a plastic guide rail, a card board, an auxiliary power circuit board, an input signal circuit board, a communication board, an analog quantity Output and pulse output boards, front cover, rear cover, liquid crystal display, plastic guide rails, card boards, auxiliary power circuit boards, input signal circuit boards, communication boards, analog output and pulse output boards are all available on the market The existing product obtained includes the following steps: a. Process the sheet material into a box body through the production system, and a prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com