Rapid slicing device for industrial wood

A slicing device and wood technology, which is applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of labor and time consumption, low safety performance, and increased contact between operators and blades, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

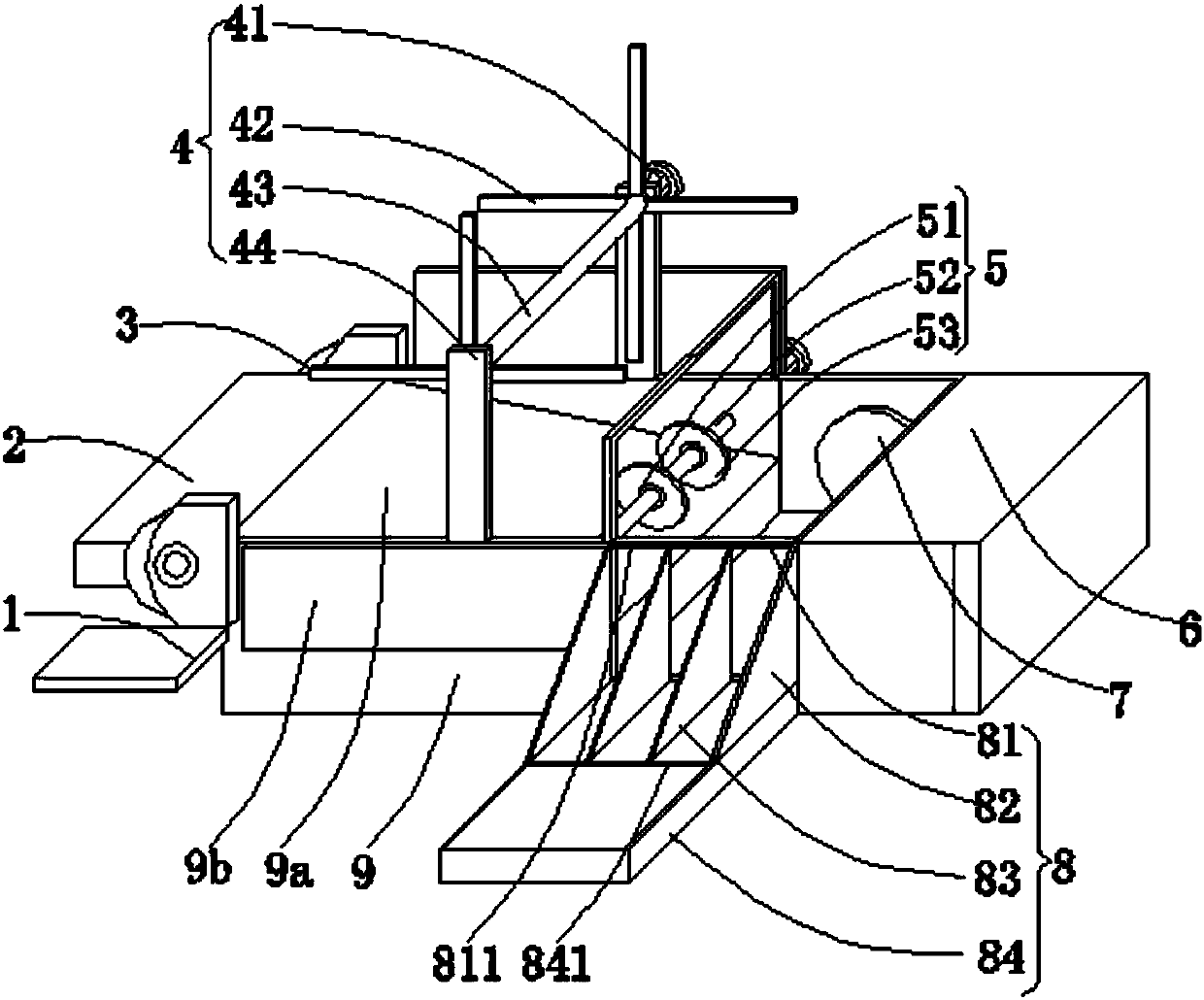

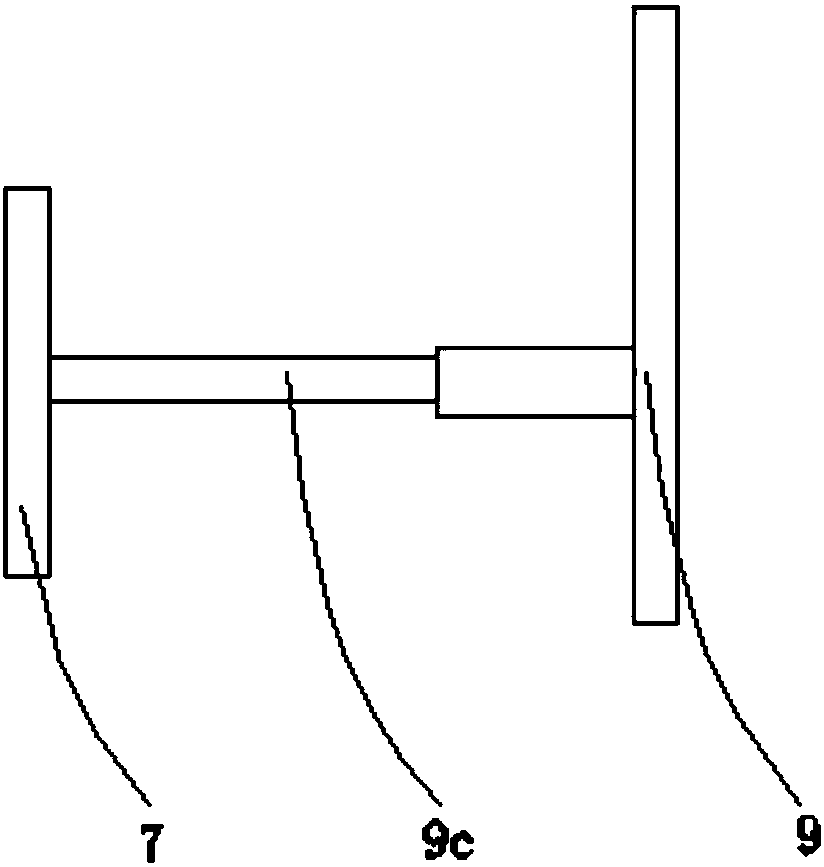

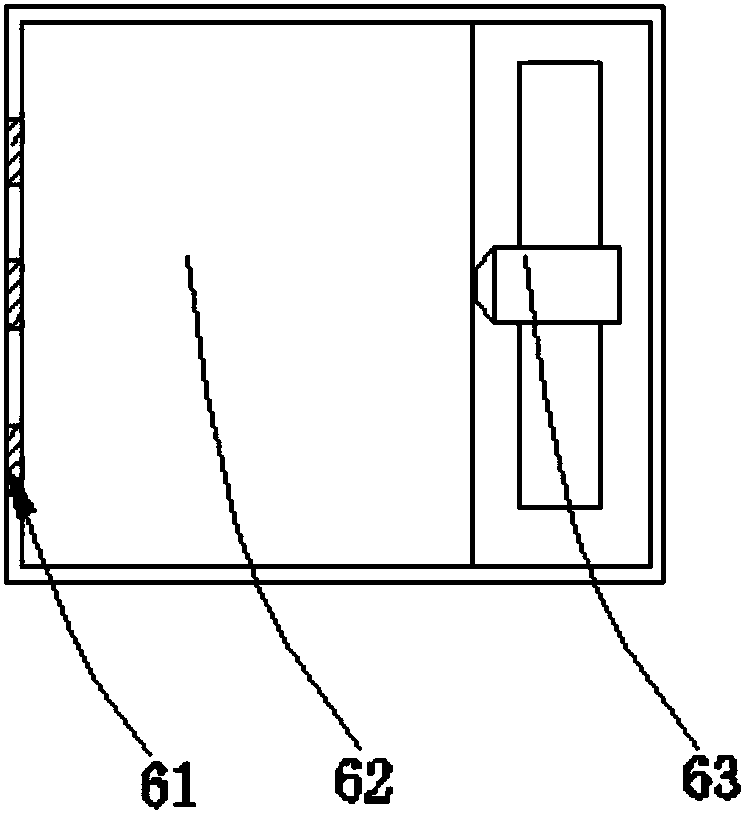

[0025] Please refer to figure 1 and figure 2 , figure 1 A schematic structural view of a preferred embodiment of the industrial wood quick slicing device provided by the present invention, figure 2 for figure 1 The schematic diagram of the connection structure between the push plate and the casing is shown. The industrial wood rapid slicing device includes a feed pallet 2; a casing 9, which is welded to the feed pallet 2; a sliding material swash plate 9a, and the sliding material swash plate 9a is arranged on the casing 9, and the sliding material swash plate 9a communicates with the feed pallet 2; the section cutting mechanism 5, the section cutting mechanism 5 includes a locking sleeve 51, a second rotating shaft 52 and a second circular blade 53, the The second rotating shaft 52 is rotatably connected to the inside of the casing 9, and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap