Foaming forming mechanical equipment

A kind of mechanical equipment and foam molding technology, which is applied to household components, applications, household appliances, etc., can solve problems such as increased energy consumption, inability to adapt to industrial production application requirements, and unsatisfactory heating and cooling speeds, so as to increase production capacity and increase Effect of water recovery and utilization rate, energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

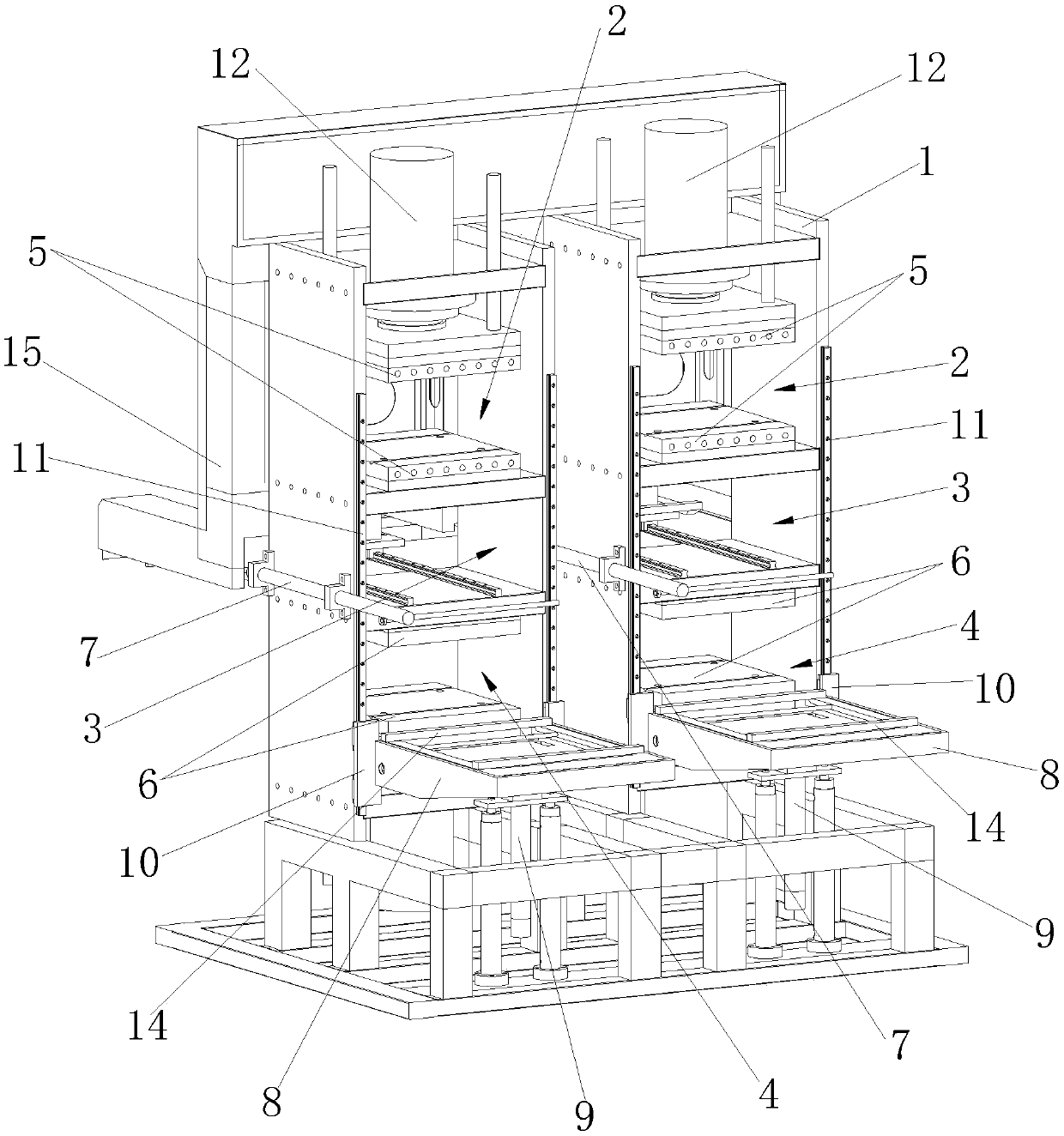

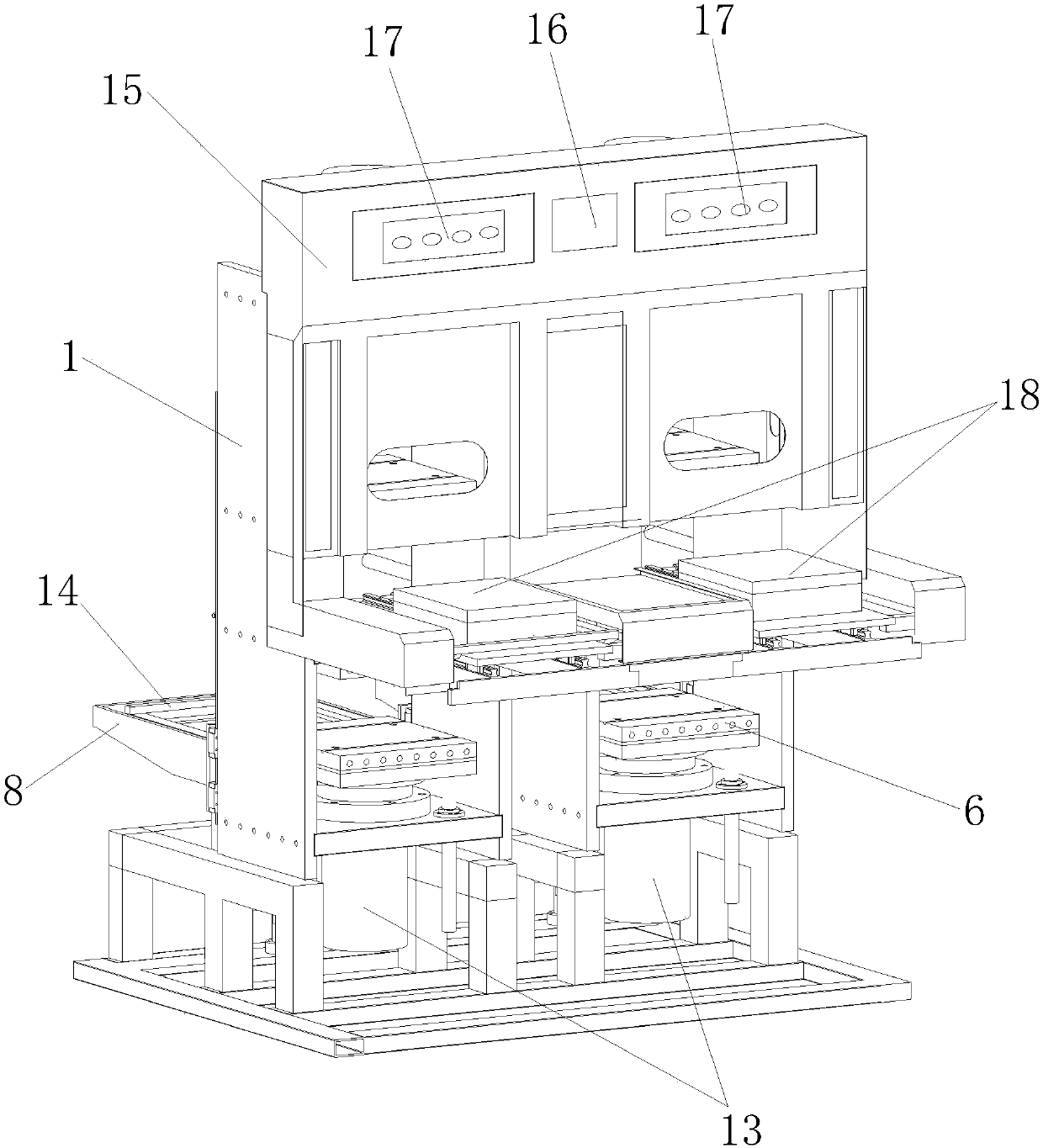

[0020] Such as figure 1 , 2 As shown, this embodiment provides a foam molding mechanical equipment, including a frame 1, and the frame 1 is sequentially provided with a mold heating station 2, a mold output station 3, and a mold cooling station in layers from top to bottom. 4. The mold heating station 2 is provided with a superconducting heating plate 5 for heating the foaming mold 18, and the mold cooling station 4 is provided with an atomizing cooling plate for cooling the foaming mold 18 6. The side of the mold output station 3 is provided with a mold ejection cylinder 7 for driving the output of the foaming mold 18, and also includes a mold heating station 2, a mold output station 3 and a mold cooling station 4. The mold exchange frame 8 that transports the foam mold 18 between them, and the lifting cylinder 9 that drives the mold exchange frame 8 to move up and down, the mold exchange frame 8 is provided with a mold delivery motor 10 for transporting the foam mold 18 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com