Immersed tube transverse moving, mooring and cable tying tripper and cable tying and cable loosening method thereof

A technology for cabling and mooring, which is applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of cabling, uncoupling difficulties, frequent lacing of large wire ropes, and difficulty in uncoupling, etc., to reduce labor intensity and improve. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

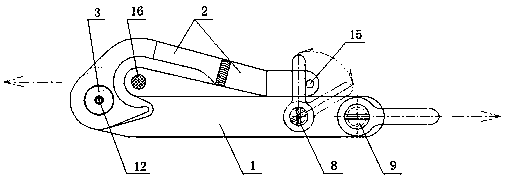

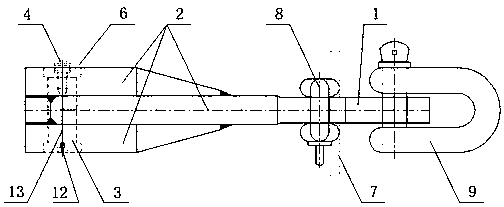

[0052] Such as Figure 1-Figure 10 As shown, the immersed tube traverse mooring cable release device includes a release device body 1 and a release arm 2. The hook end of the release arm 2 is hinged with the release device body 1, so that the release arm 2 can be Rotate around the hinge point, the connecting end is detachably connected with the release body 1, and the detachable connection end of the release body 1 is provided with a connection structure for connecting towed objects. The release arm The hook end of 2 has a circular arc structure, and the circular arc structure is closed with the release body 1 to form a space for accommodating the towing cable 16 .

[0053] The connecting structure is a towing shackle 9 , which is arranged at the end of the release body 1 , so that the towing shackle 9 can rotate around the end of the release body 1 .

[0054] A towing shackle pin hole 19 is provided at the end of the tripper body 1, so that the towing shackle 9 is installed ...

Embodiment 2

[0069] Such as figure 2 and image 3 As shown, the method for carrying the cable of the immersed tube laterally moving mooring cable release includes the following steps:

[0070] a. Connect the towed object, and connect the towed shackle 9 with the towed object;

[0071] b. Hang the towing cable 16, and insert the end loop of the towing cable 16 into the hook at the hook end of the tripping arm 2;

[0072] c. Close the trip arm 2, turn the trip arm 2 so that its connection end is closed with the trip body 1;

[0073] d. Complete the connection between the trip arm 2 and the trip body 1, turn the trip shackle 8, buckle the hook handle 10 of the trip arm 2, and insert the safety pin 7.

[0074] By adopting the above method, the problem of frequent and difficult carrying of large steel wire ropes is solved, the labor intensity of workers carrying cables is greatly reduced, and the work efficiency of workers is improved. On the hook, the trip arm transmits the force to the r...

Embodiment 3

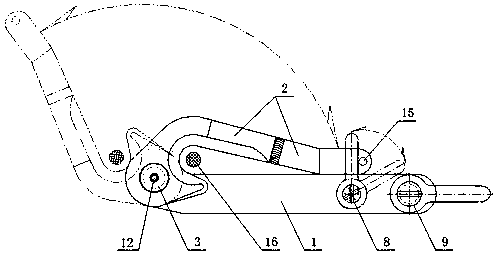

[0076] Such as figure 2 and image 3 As shown, the unmooring method of the immersed tube traversing mooring cable release includes the following steps:

[0077] a. Pull out the safety pin 7 at the connection end of the trip arm 2;

[0078] b. Knock the tripping shackle 8 to disengage the hook handle 11;

[0079] c. Under the action of the cable's self-gravity or light load, the tripping arm 2 is rotated and opened around the connecting pin shaft 3 .

[0080]By adopting the above method, the difficult problem of unmooring the large steel wire rope is solved, the labor intensity of the workers carrying the cables is greatly reduced, and the work efficiency of the workers is improved. Since the drag force of the towing cable acts on the hook on the trip arm, its force line leaves the center of the connecting pin shaft, so that the drag force of the cable produces a rotational moment relative to the axis of the trip arm, so that the trip arm Rotate around the connecting pin s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com