Disc engine drive device

An engine-driven, engine technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of low energy utilization, large environmental pollution, waste of component forces, etc., to maximize conversion efficiency, exhaust emissions The effect of lowering and lowering fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

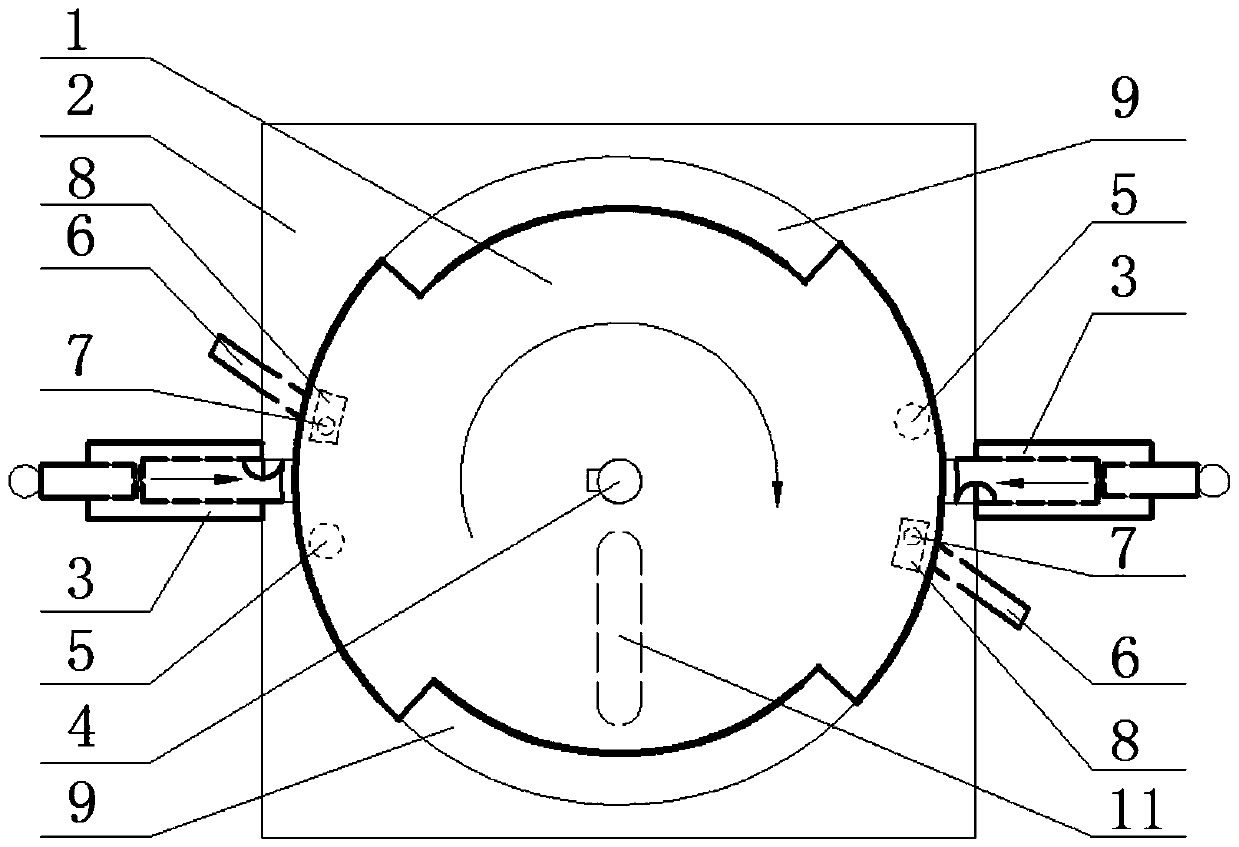

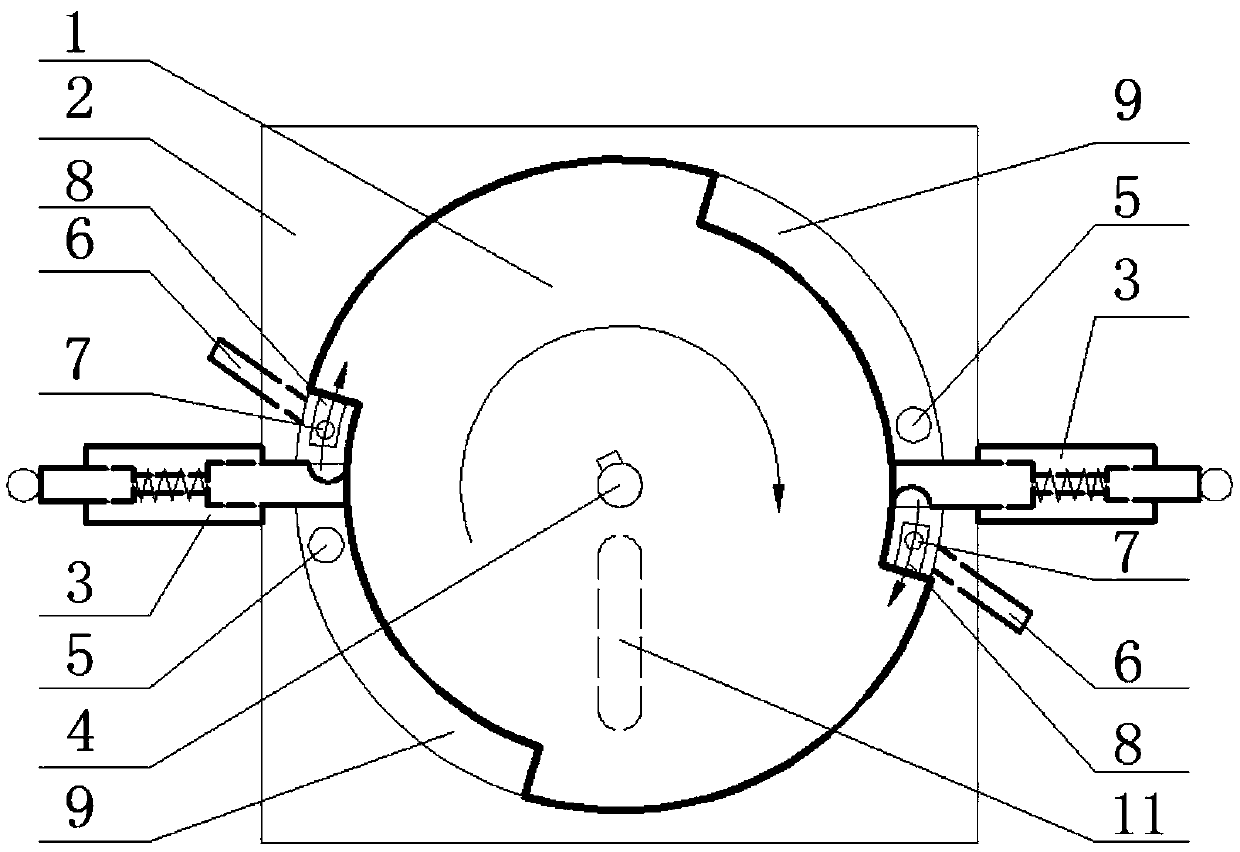

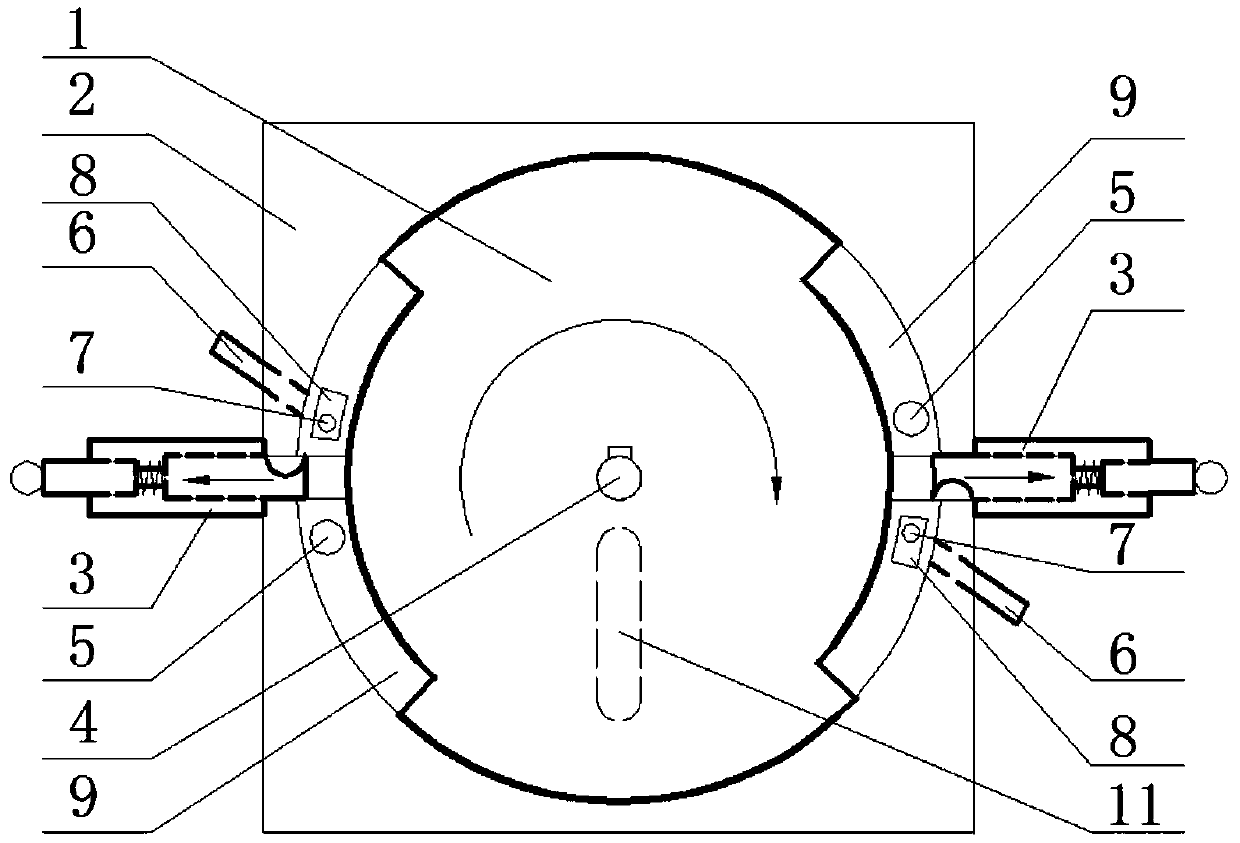

[0038] figure 1 , figure 2 , image 3 Shown separately are operating state diagrams of different stages of an ignition engine with a double combustion chamber. First, the starting device starts to drive the engine main shaft 4 to drive the flywheel 1 to rotate. When the front edge of the combustion chamber 9 reaches the position of the impact block device, the impact block (in advance, rapidly or delayed) enters the combustion chamber 9. The driving flywheel 1 continues to rotate, and the impact block divides the combustion chamber 9 into two sub-combustion chambers of the oil-gas hole combustion chamber and the exhaust hole combustion chamber. Simultaneously, the compressed oil-air mixture is pressed into the temporary gas storage chamber 8 by the oil-gas injection ignition device. The combustion chamber 9 continues to rotate, and the gas in the exhaust hole combustion chamber is discharged by the exhaust hole 5. When the intake hole combustion chamber rotates to the pos...

Embodiment 2

[0040] Figure 4 , Figure 5 , Figure 6 Shown separately are the working state diagrams of different stages of a compression ignition embodiment with dual combustion chambers. The starting device starts to drive the engine main shaft 4 to drive the flywheel 1 to rotate, and when the front edge of the combustion chamber 9 reaches the impact block device position, the impact block (in advance, rapidly or time delay) enters the combustion chamber 9. The driving flywheel 1 continues to rotate, and the impact block divides the combustion chamber 9 into two sub-combustion chambers, the oil-gas aperture combustion chamber and the exhaust aperture aperture combustion chamber. Simultaneously, the compressed high-pressure and high-temperature gas is pressed into the temporary gas storage chamber 8 by injecting oil and gas into the ignition device. The combustion chamber 9 continues to rotate, and the gas in the exhaust hole combustion chamber is discharged by the exhaust hole 5. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com