Efficient heat exchanging auto air-condition compressor

A technology for automotive air conditioners and compressors, applied in mechanical equipment, vehicle parts, air handling equipment, etc., can solve the problems of excessive refrigerant, reduced cooling effect, and low heat exchange efficiency of heat exchangers, and achieve enhanced wear resistance and heat-resistant viscosity, prevent uneven distribution, and enhance the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying tables and specific embodiments.

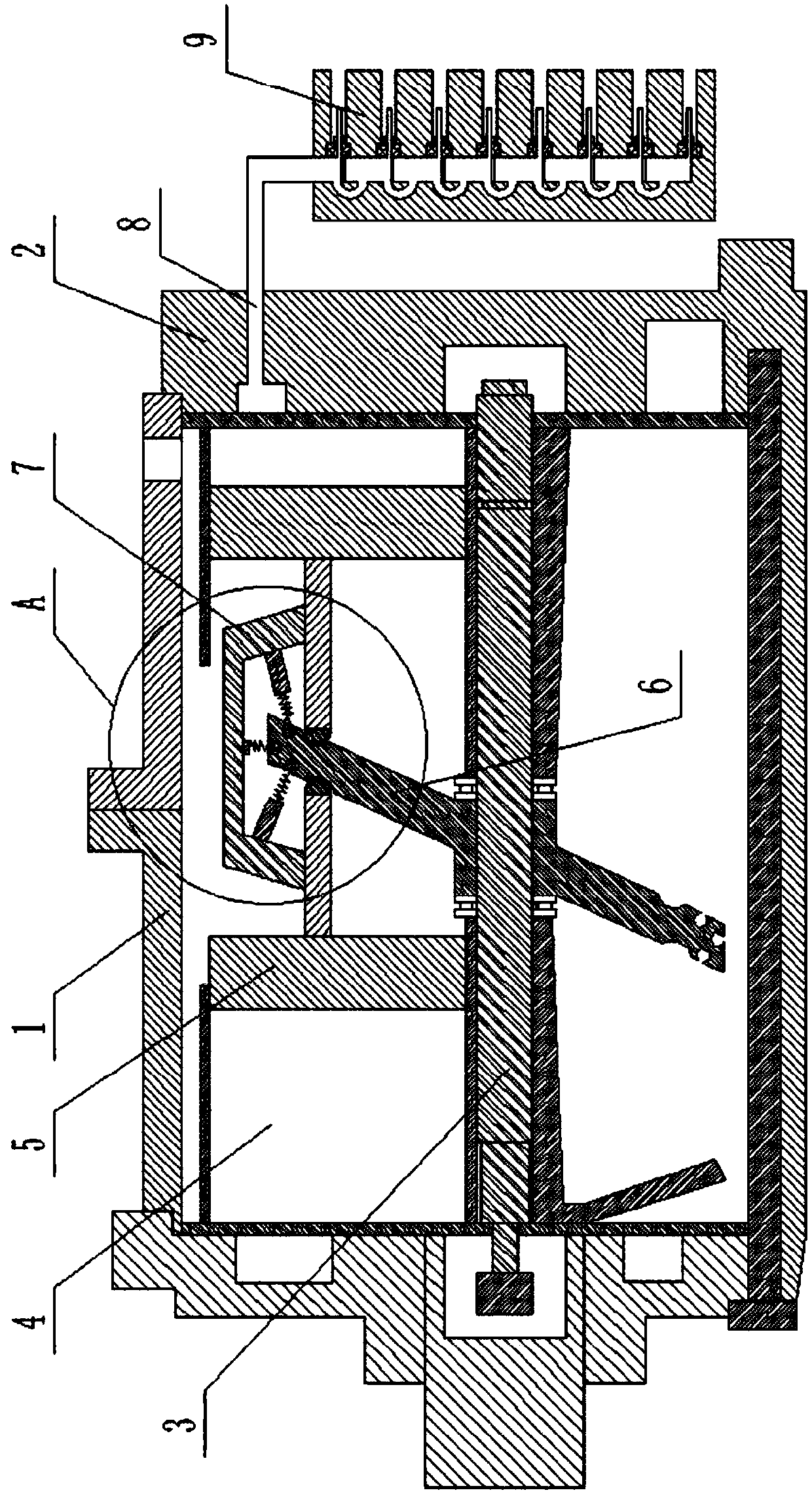

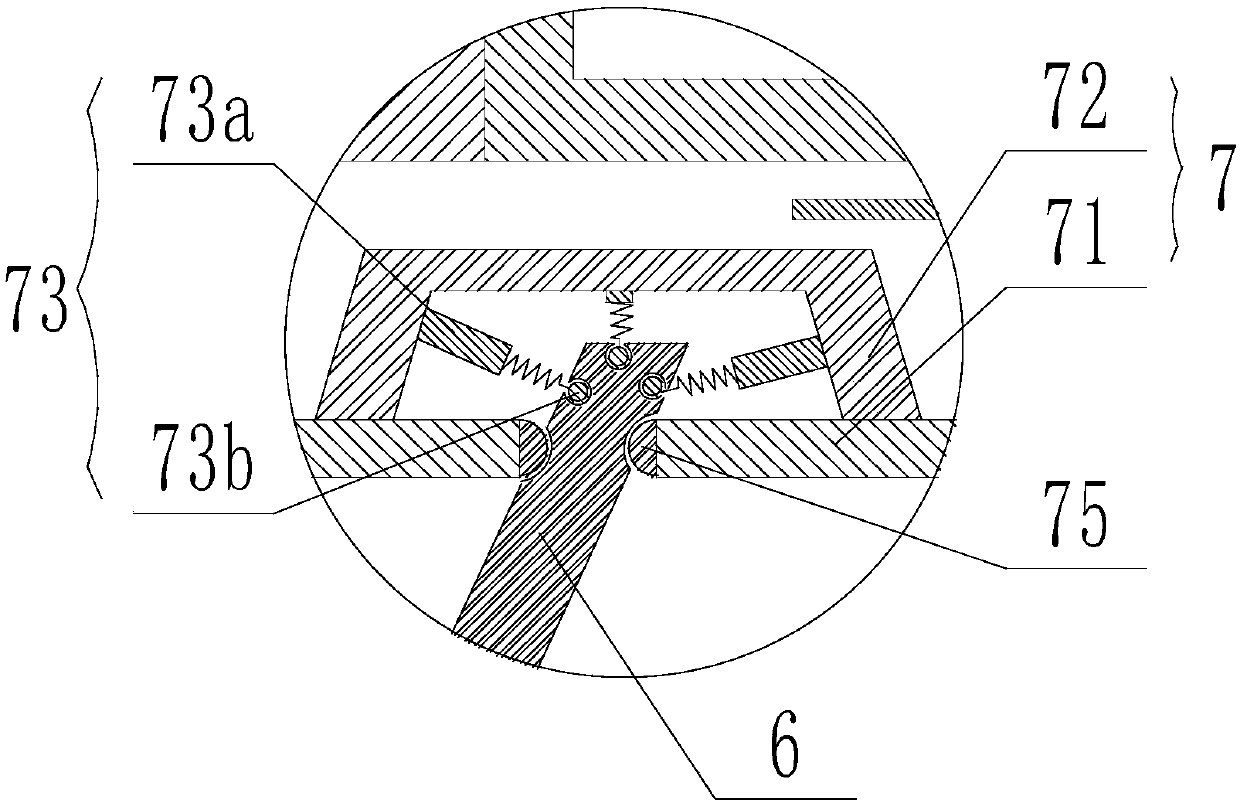

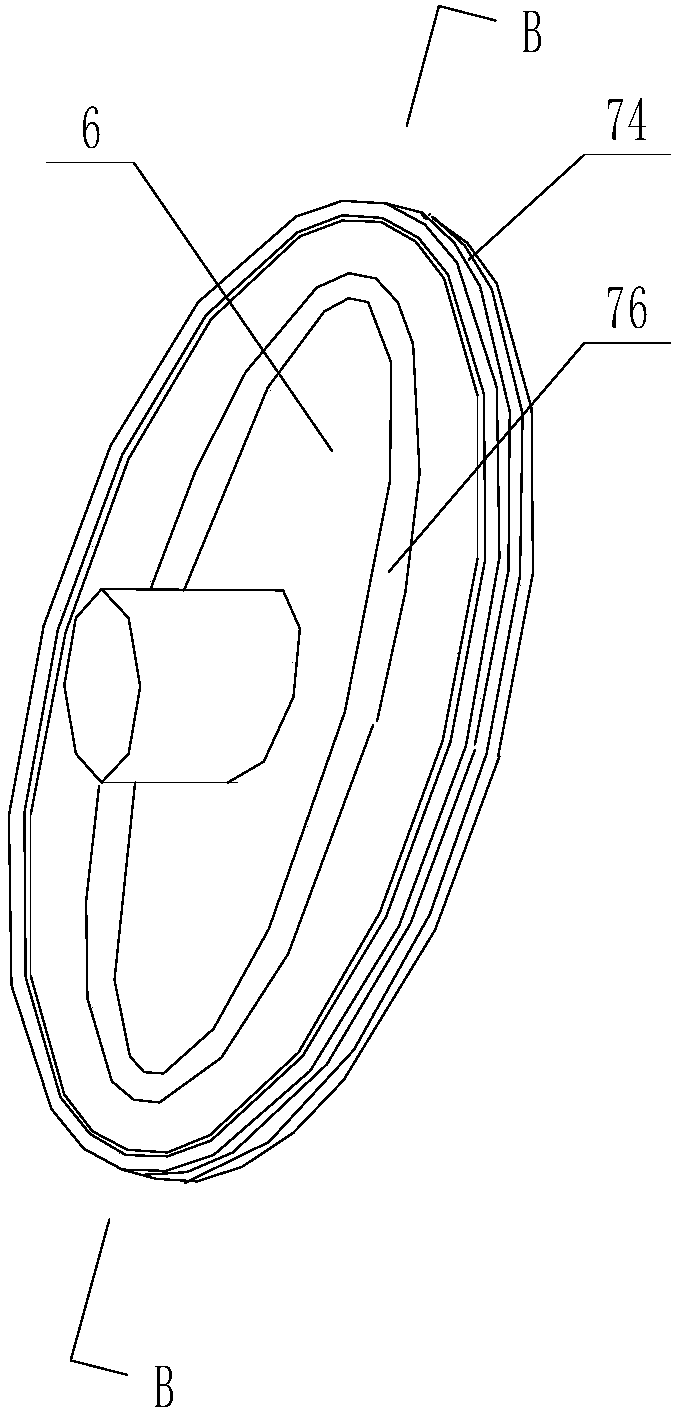

[0032] Such as Figure 1-5 As shown, a high-efficiency heat-exchanging automotive air-conditioning compressor includes a cylinder body 1, a cylinder head 2, and a drive spindle 3. The drive spindle 3 is axially installed in the cylinder body 1, and the drive spindle 3 and the The axis lines of the cylinder body 1 coincide, and the cylinder body 1 is horizontally provided with three piston-cylinder groups 4, and the three piston-cylinder groups 4 are evenly distributed around the drive spindle 3; the piston-cylinder groups 4 are two Confronting the set piston cylinders, the two piston cylinders are distributed sequentially along the axial direction of the drive spindle 3, the two piston cylinders are respectively provided with match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com