Continuous chili drying machine

A drying machine and pepper technology, applied in progressive dryers, dryers, drying solid materials, etc., can solve the problems of high requirements on natural conditions, unfavorable long-term development of enterprises, slow light loss of pepper water, etc., and save labor. The effect of resources, reduced manual participation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

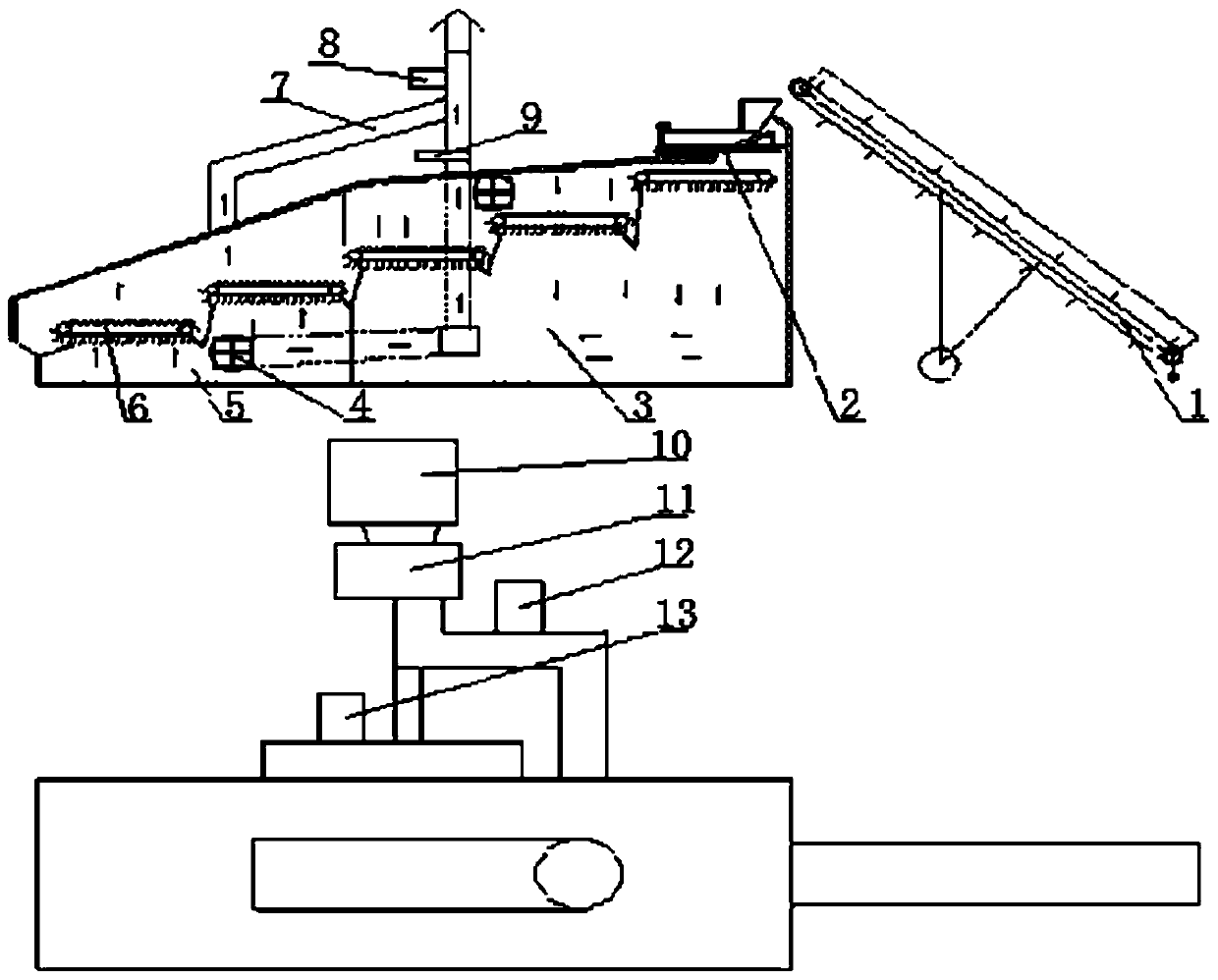

[0017] exist figure 1 Among them, including hoist, material distribution device, first drying chamber, air homogenizer, second drying chamber, conveyor belt, moisture outlet, dust collector, moisture outlet regulating valve, hot blast stove, heat exchanger, main air duct fan and Regulating valve, secondary air channel fan and regulating valve, in which the selected peppers are sent to the scraper type material elevator (1), and then the peppers are sent to the distributing device (2) of the continuous dryer; the distributing device sends the peppers Evenly distributed on the conveyor belt (6); the conveyor belt of the dryer drives the peppers to move forward slowly, and the pepper layer is dried by the hot air during the movement; when the moisture content of the peppers is reduced to 14%, it is discharged from the discharge port for drying. Warehouse (5); after the dried peppers are cooled and relieved, the peppers can be stored in bags.

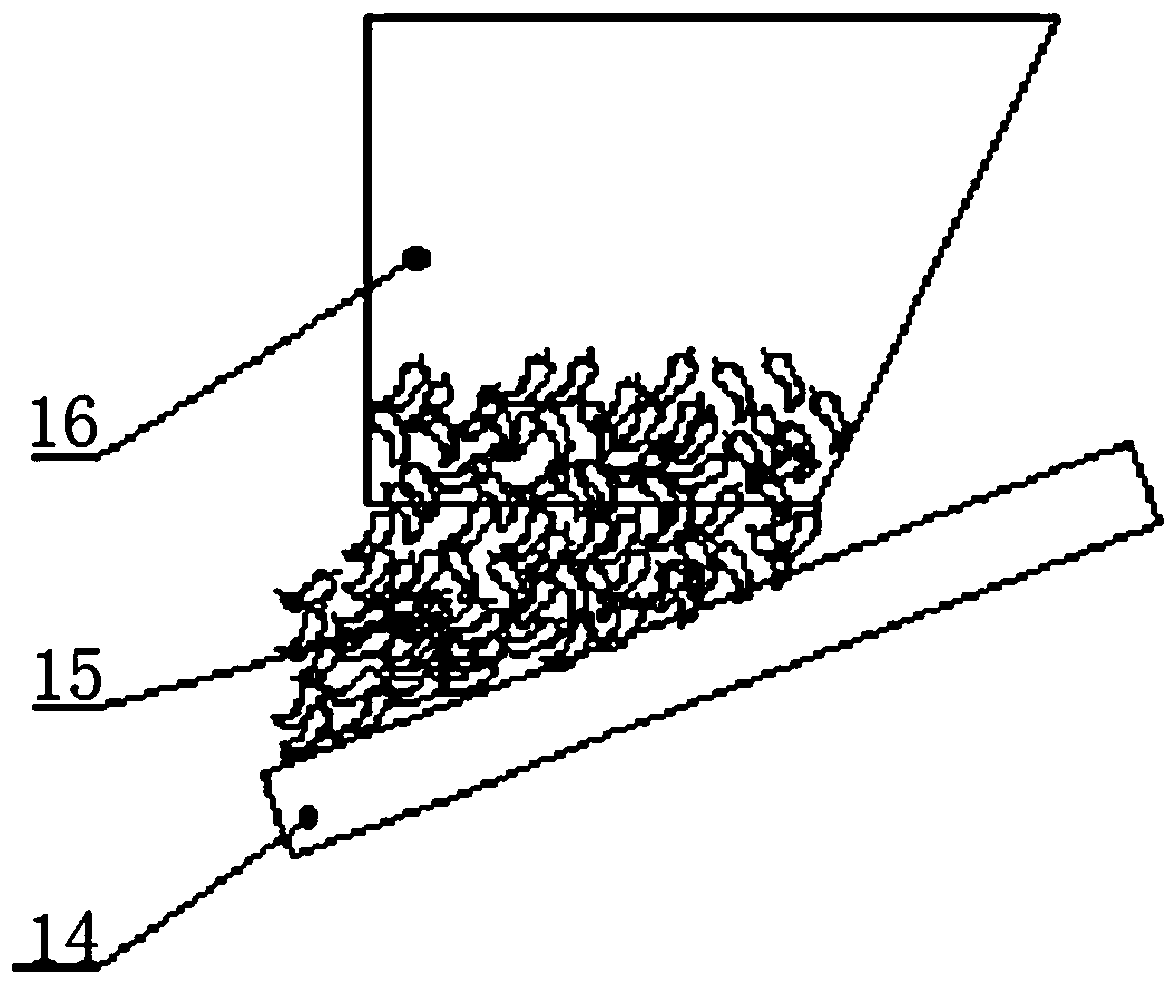

[0018] exist figure 2 Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com