Method used for detecting tempered glass tableware spontaneous explosion hidden troubles, and applications thereof

A technology for tempered glass and tableware, which is applied in the preparation of test samples, measuring devices, and material analysis through optical means. It can solve the problems of no self-explosion detection method for tempered glass tableware, inapplicability of curved tempered glass, and inapplicability of stress detection. and other issues to achieve the effect of reducing self-explosion rate, low cost and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take the heart-shaped tempered glass tableware recorded in the patent CN200830282532.4 as an example to verify the accuracy of the method of the present invention, as follows:

[0033] Randomly select 10 batches of tempered glass tableware of the above shape produced in the workshop, randomly select 2,000 samples for each batch, and select a total of 20,000 samples for the experiment. The 20,000 samples were divided into two groups according to batches, and two methods were used to detect self-explosion.

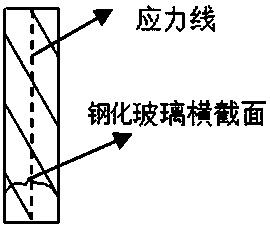

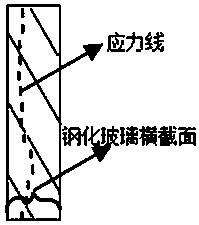

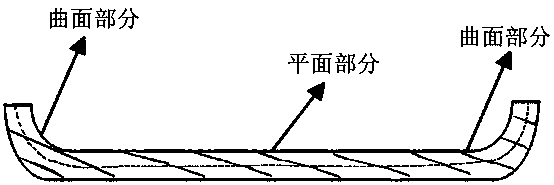

[0034] Among them, 10,000 samples adopt the method of the present invention to detect self-explosion. The steps are: use an impact hammer to conduct a destructive fragment test on each tempered glass tableware sample. The sample is subjected to instantaneous impact crushing, and the tempered glass particles stick to the scotch tape after crushing, and the size of each particle is about 5cm×5cm. Select two types of tempered glass particles in the plane part and the la...

Embodiment 2

[0043] In the actual production process of toughened glass tableware, the hidden danger of self-explosion can be detected by the method of the present invention to control the quality of the delivered product. The quality control method is:

[0044] 1. When producing each batch of tempered glass tableware, conduct random sampling inspection according to the quantity of tempered glass tableware products. The sampling quantity is as follows:

[0045] Each batch of 3000 or less, the sampling quantity is 5;

[0046] Within 3001-5000 per batch, the sampling quantity is 10;

[0047] Within 5000-10000 per batch, the sampling quantity is 15;

[0048] More than 10,000 samples per batch, 30 samples;

[0049] 2. Quality control method

[0050] Use an impact hammer to test each tempered glass tableware sample for destructive fragments. First, stick a scotch tape on the surface of the sample, and use an impact hammer to break the sample instantly at a distance of 0.5 cm from the edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com