Visual lens

A lens and vision technology, applied in optical components, optics, instruments, etc., can solve problems such as shortening the object distance, and achieve the effect of reducing high-order aberrations, meeting costs, and high relative illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

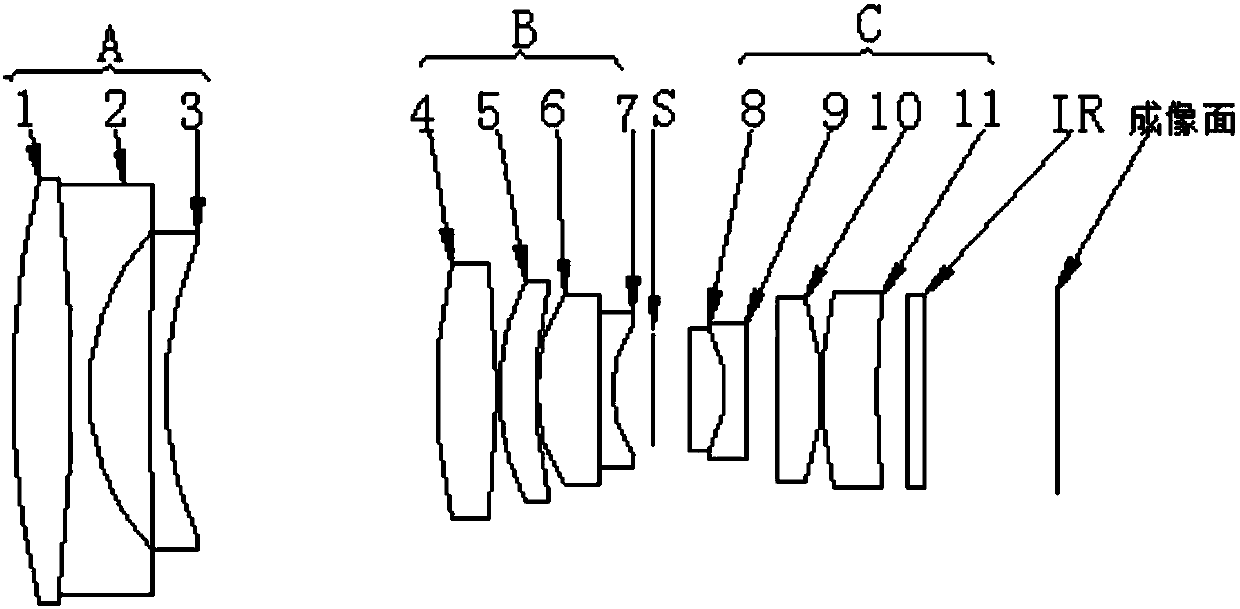

[0073] According to an embodiment of the present invention, when the second lens group B includes three lenses, the second lens group B can be composed of a fourth lens 4 with positive refractive power, a fifth lens 5 with negative refractive power, and a fifth lens with negative refractive power. The sixth lens 6 is composed of positive refractive power. In this embodiment, the refractive power of each lens in the second lens group B can also be set in other ways, as long as the overall refractive power of the second lens group B is guaranteed to be positive.

[0074] In this embodiment, the third lens group C includes a seventh lens 7 with positive power, an eighth lens 8 with negative power, a ninth lens 9 with positive power, and a tenth lens with positive power. Lens 10.

[0075] In this embodiment, the first lens 1 and the second lens 2 constitute a cemented lens group, and the fourth lens 4 and the fifth lens 5 constitute a cemented lens group. The seventh lens 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com