Compensation structure of drive circuit, drive circuit module and display panel

A technology of driving circuit and compensation structure, applied in static indicators, instruments, etc., can solve the problems of easy interference of voltage signals, higher and higher requirements for analog-to-digital conversion accuracy, and lower voltage values, so as to overcome the sensing voltage Reduce, shorten the sensing time, realize the effect of calibration function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment aims at the problems existing in voltage-type external compensation, and provides a compensation structure for a current-type driving circuit. The compensation junction can effectively compensate the driving circuit and ensure compensation accuracy.

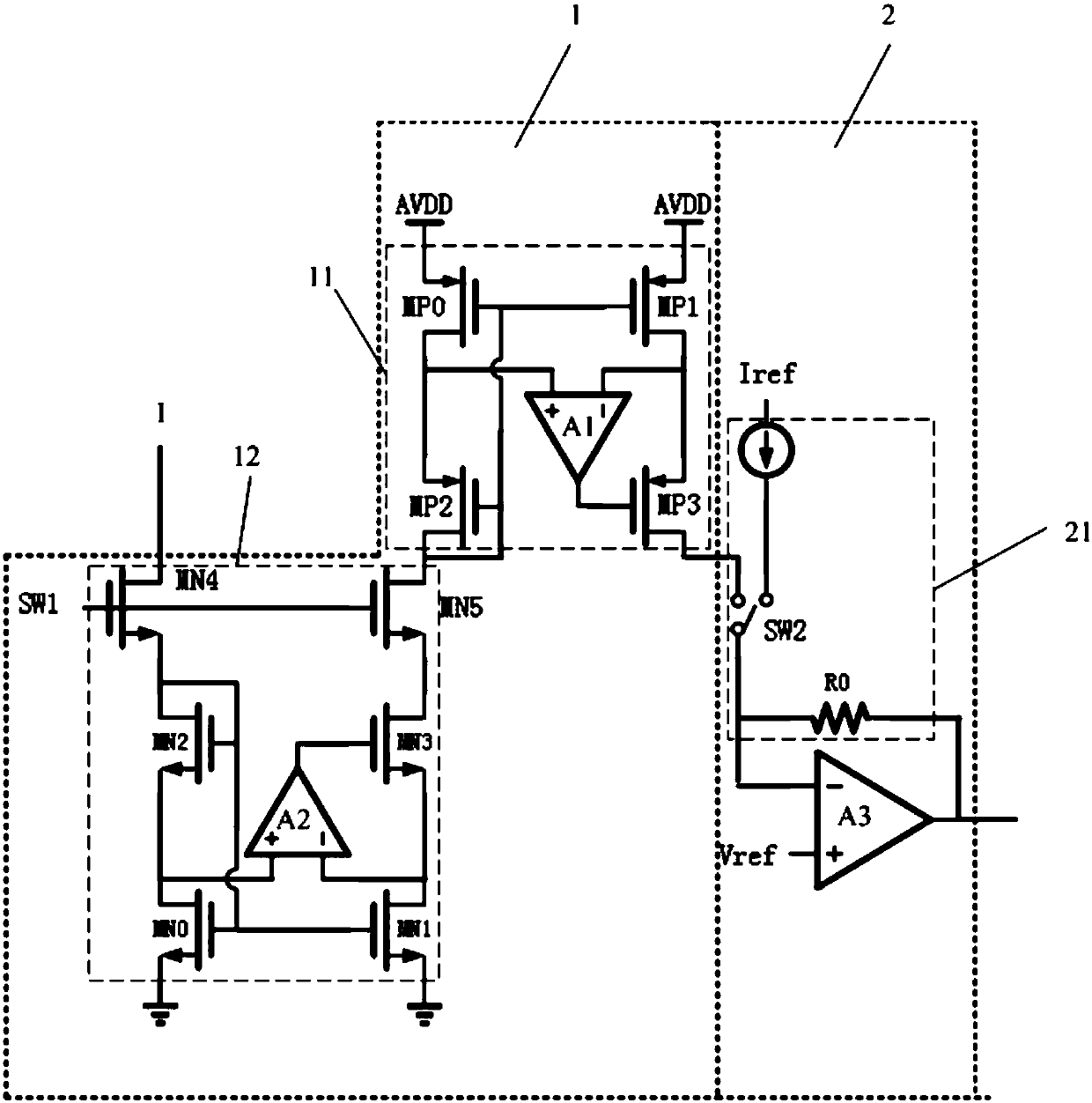

[0050] The compensation structure of the drive circuit is used to provide compensation current for the drive circuit, such as figure 1 As shown, it includes a current amplifying circuit 1 and a cross-group amplifying circuit 2, wherein:

[0051] The current amplification circuit 1 is connected to the output end of the driving circuit, and is used to amplify the driving current output by the driving circuit by a set factor;

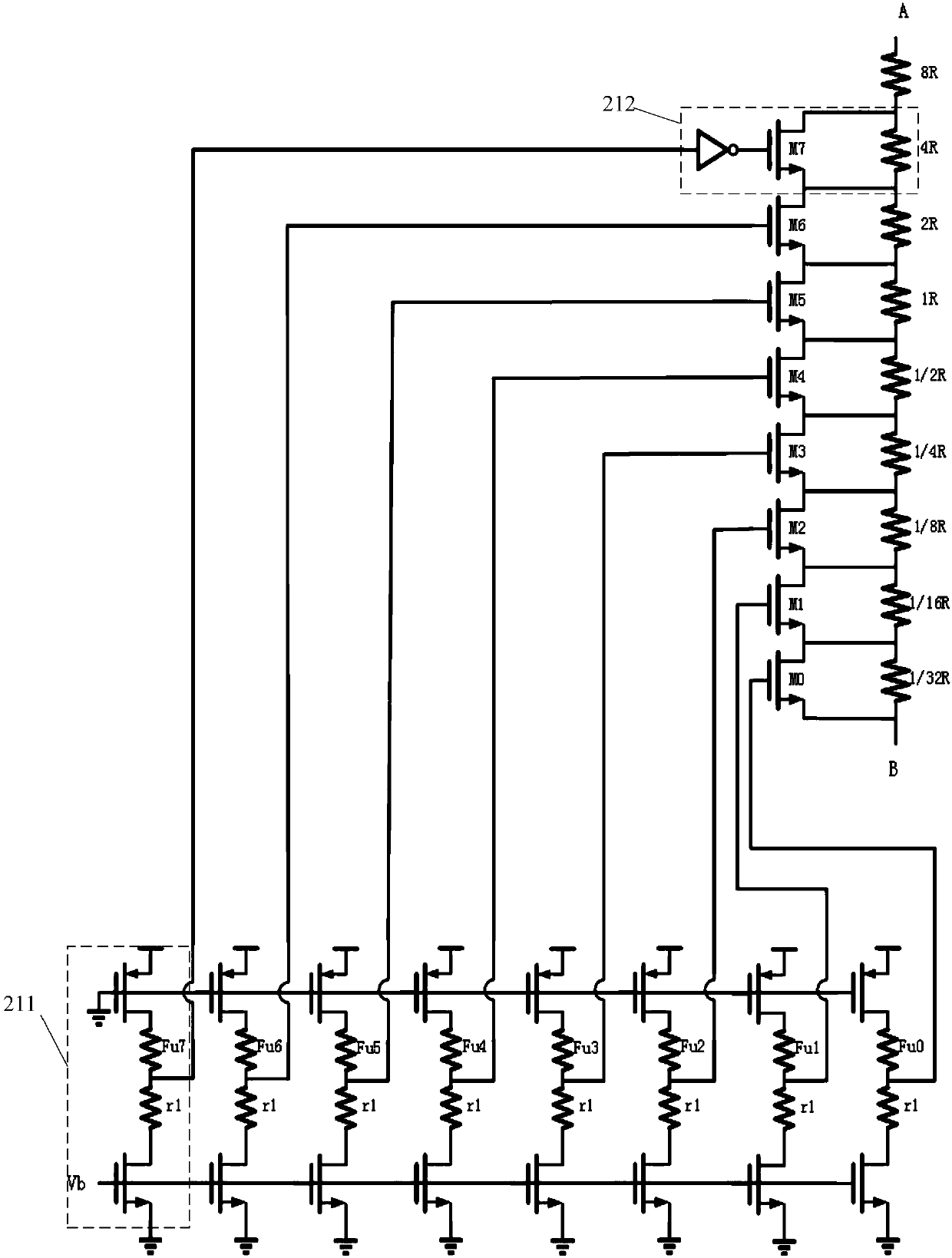

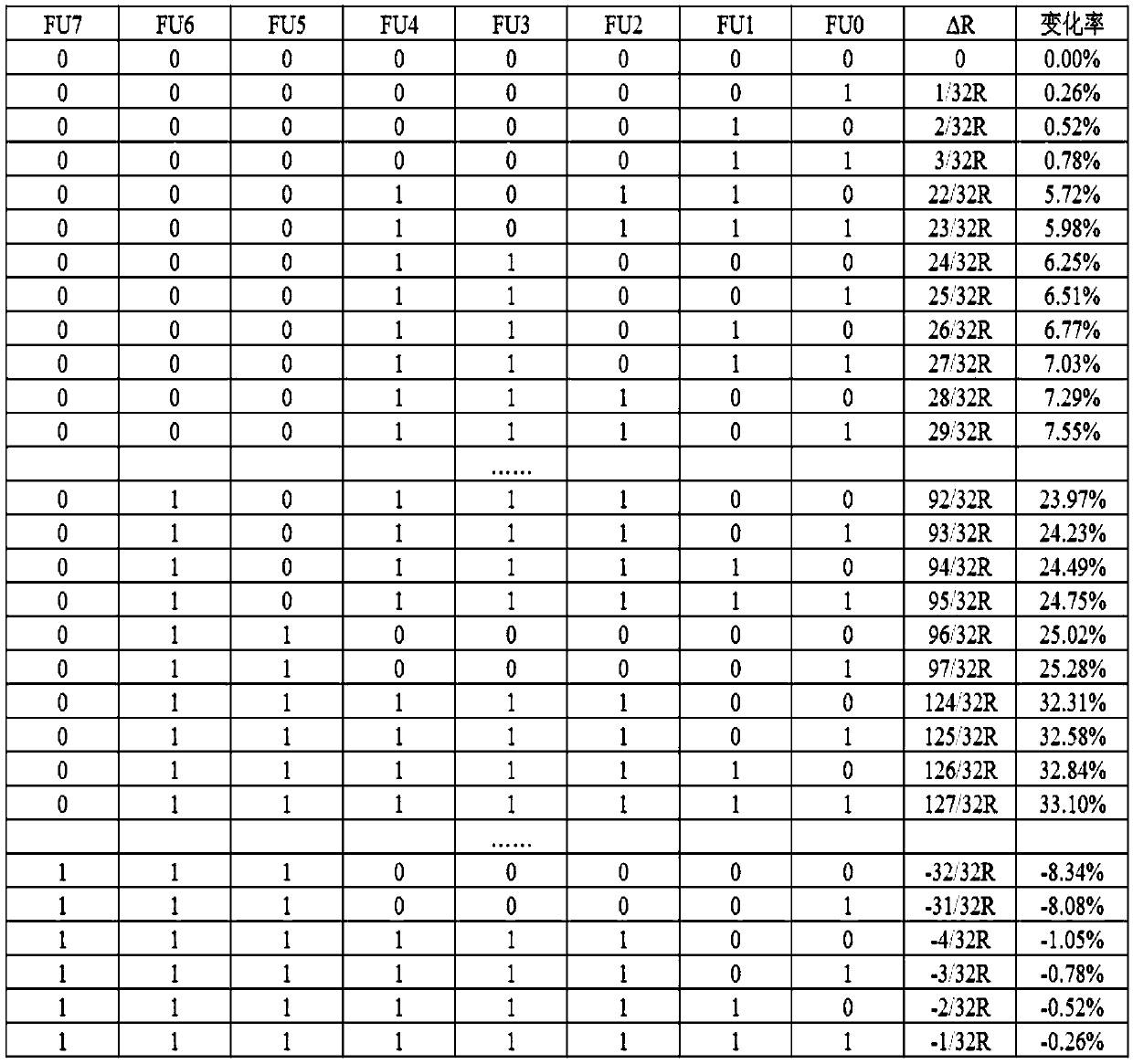

[0052] The cross-group amplifying circuit 2 is connected to the output terminal of the current amplifying circuit 1, and is used for matching the resistance in the compensation structure and converting the driving current into a corresponding driving voltage. Usually, an operational am...

Embodiment 2

[0087] This embodiment provides a driving circuit module, which includes a driving circuit and the compensation structure of the driving circuit in Embodiment 1, which has a better driving effect.

[0088] In the driving circuit module, there is no limitation on the structure of the driving circuit therein. As an example, such as Figure 4 As shown, the driving circuit 3 is a common 2T1C pixel circuit, and T1 is a scanning switch tube, which is responsible for writing the driving voltage data (Data) into the gate of the driving tube T2 row by row; T2 is the driving tube, which converts the voltage signal into Current is supplied to the OLED device. The gate of T1 is connected to the scan signal, the source is connected to Data data; the gate of T2 is connected to the drain of T1, the source is connected to OVDD, the drain is connected to the anode of OLED, the anode of the OLED device is connected to the drain of T2, and the cathode is grounded.

[0089] When the current-typ...

Embodiment 3

[0093] This embodiment provides a display panel, which further includes the compensation structure of the driving circuit in the second embodiment.

[0094] The display panel can be: desktop computer, tablet computer, notebook computer, mobile phone, PDA, GPS, vehicle display, projection display, video camera, digital camera, electronic watch, calculator, electronic instrument, instrument, LCD panel, electronic paper, TV Computers, monitors, digital photo frames, navigators and any other products or components with display functions can be applied to multiple fields such as public display and virtual display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com