Prefabricated cable intermediate joint adopting composite material with electrical conductivity being adaptively regulated and controlled

A technology of cable intermediate joints and self-adaptive control, which is applied in the direction of cable accessories, cable installation, electrical components, etc., can solve the problems of field strength concentration and limitation, and achieve improved reliability, expanded application range, and good field strength uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

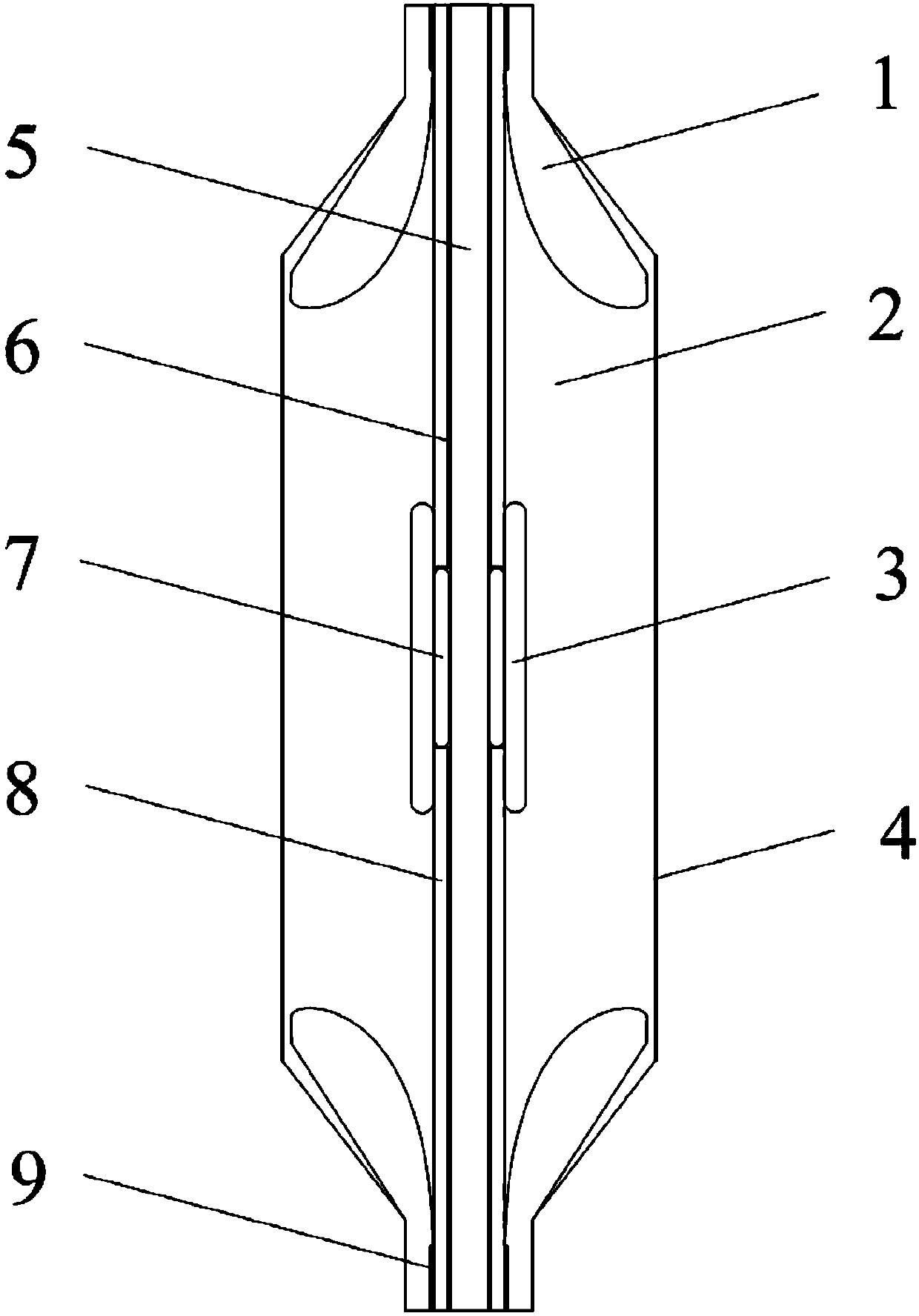

Embodiment 1

[0019] Embodiment 1: This embodiment is used for AC cable connection with a voltage level of 110kV. The zinc oxide varistor ceramic powder particles used in the stress cone 1 account for 35% of the volume percentage of the conductivity adaptive regulation composite material, and the particle size is 150 μm-175 μm, the zinc oxide varistor ceramic powder particles used in the high-voltage shielding layer 3 account for 45% of the volume percentage of the conductivity self-adaptive regulation composite material, and the particle size is 120 μm-150 μm.

Embodiment 2

[0020] Embodiment 2: This embodiment is used for DC cable connection with a voltage level of 500kV. The zinc oxide varistor ceramic powder particles used in the stress cone 1 account for 25% of the volume percentage of the conductivity self-adaptive control composite material, and the particle size is 40 μm-75 μm, the zinc oxide varistor ceramic powder particles used in the high-voltage shielding layer 3 account for 40% of the volume percentage of the conductivity self-adaptive regulation composite material, and the particle size is 75 μm-100 μm.

Embodiment 3

[0021] Embodiment 3: This embodiment is used for AC cable connection with a voltage level of 35kV. The zinc oxide varistor ceramic powder particles used in the stress cone 1 account for 45% of the volume percentage of the conductivity self-adaptive regulation composite material, and the particle size is 150 μm-175 μm, the zinc oxide varistor ceramic powder particles used in the high-voltage shielding layer 3 account for 50% of the volume percentage of the conductivity self-adaptive regulation composite material, and the particle size is 175 μm-200 μm.

[0022] The working principle of the present invention: the composite material with self-adaptive control of electrical conductivity is used as the material of the cable intermediate joint attachment to realize the adaptive matching between the material performance parameters and the strength of the space field, and play the role of intelligently improving the space field strength; the middle of the cable Where the local field st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com