Electromechanical assembly comprising electrical machine coupled to reduction gear

A technology of electromechanical components and deceleration devices, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of spline wear and service life, and achieve the effect of improving retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

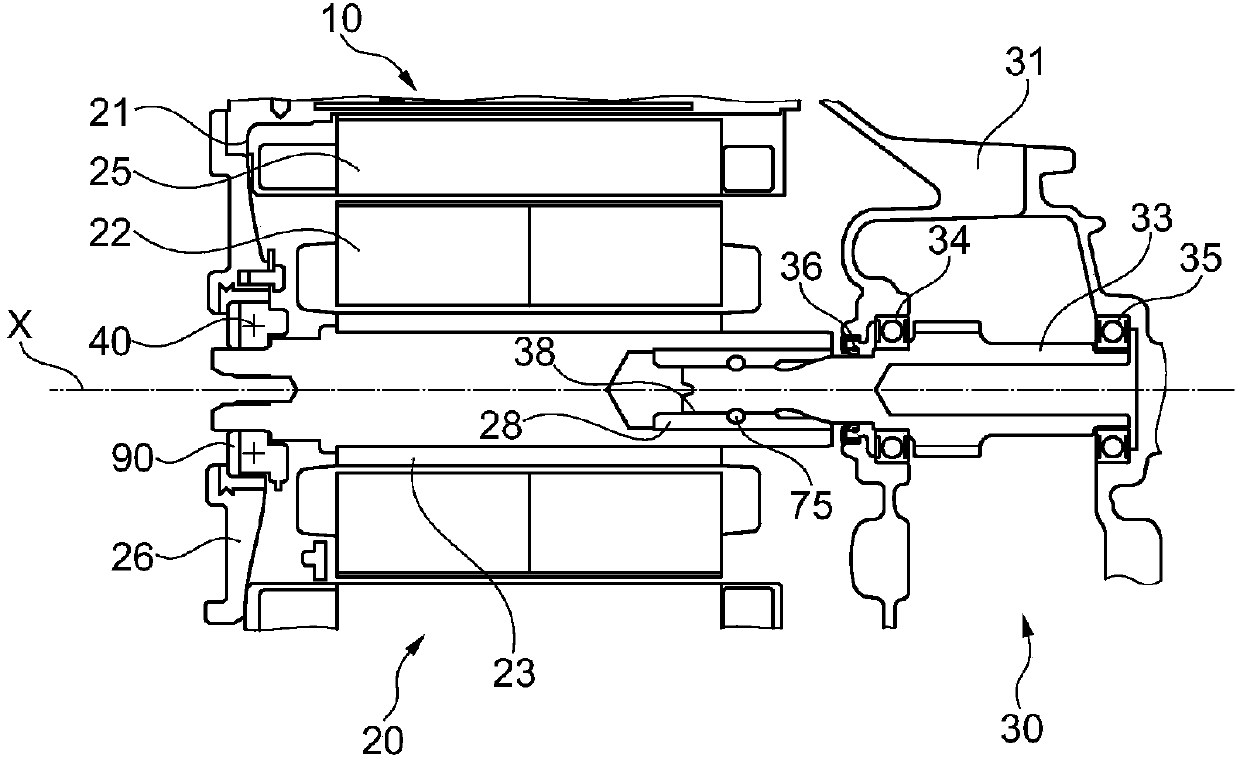

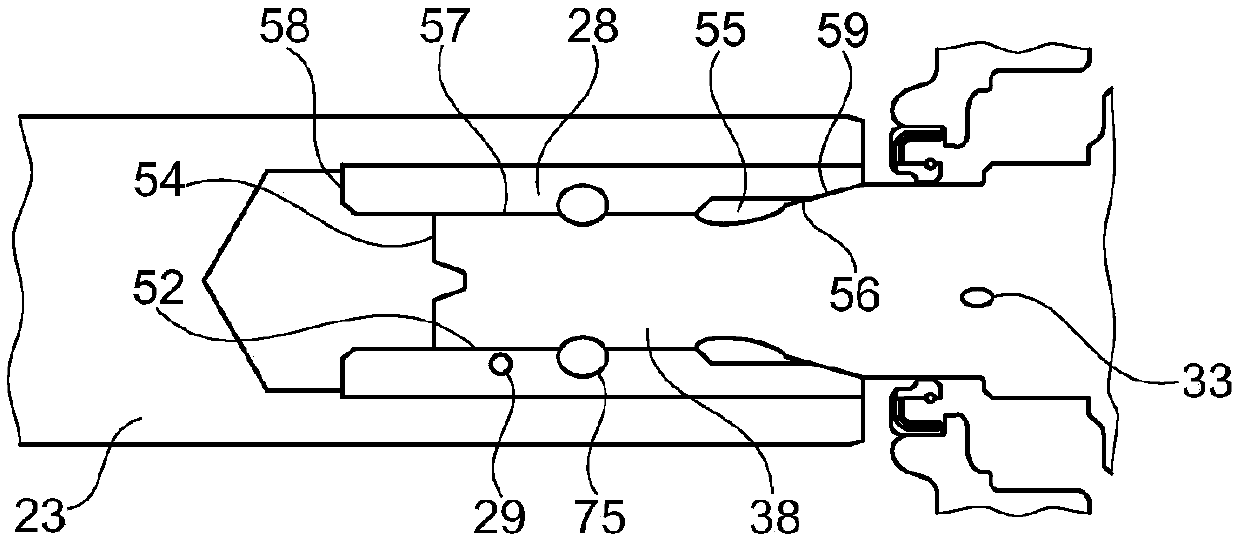

[0023] figure 1 The assembly 10 shown in includes a motor 20 and a reduction gear 30 coupled to the machine 20.

[0024] The machine 20 and the reduction gear 30 include respective housings 21 and 31 connected together by bolts, for example.

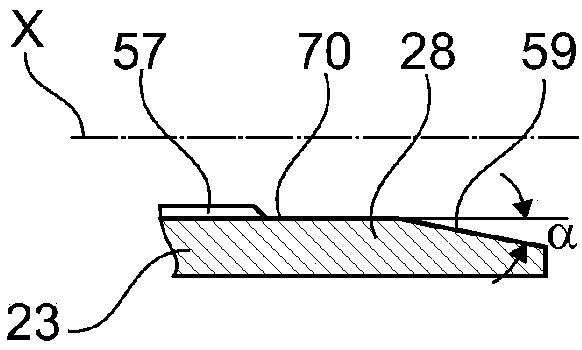

[0025] In the example considered, the machine 20 is an electric motor and includes a rotor 22, the shaft 23 of which can rotate about the axis X.

[0026] The rotor 22 is located in the stator 25.

[0027] The machine 20 may be a motor with permanent magnets.

[0028] The shaft 23 is supported at the rear by a bearing 40 which is carried by the flange 26 of the machine 20.

[0029] The reduction gear 30 includes an input shaft 33 which is guided forward and backward through corresponding bearings 34 and 35.

[0030] Bearing 40, bearing 34 and bearing 35 are preferably ball bearings.

[0031] As shown, a lip seal 36 may be provided, which is applied to the shaft 33 in front of the bearing 34. The seal can hold the grease of the reduction gear.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com