Corrosion resistant buried underground ductile cast iron piping members with an improved external coating and the method thereof

一种铸铁管件、外部涂层的技术,应用在涂层、化学仪器和方法、金属材料涂层工艺等方向,能够解决优点存在争议等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

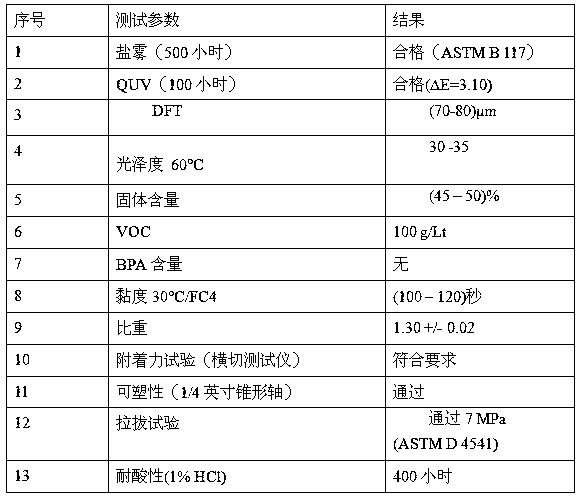

[0032] It is an object of one embodiment of the present invention to provide a pseudo-alloy coating of any alloy composition and a second coat of a CNSL modified resin coating that produces very useful results when applied to pipe fittings.

[0033] It is an object of another embodiment of the present invention to provide a corrosion resistant, renewable and biorenewable resin coating for plumbing fittings which has improved corrosion resistance as discussed in prior patents, but is more economical, cheap, Convenient, safe, and more competitive, and this paint does not contain bisphenol A (BPA) and low content of volatile organic compounds (VOC), which are harmful to health.

[0034] And the purpose of another embodiment is to provide a kind of method that is coated with zinc-aluminum pseudo-alloy on the outer surface of buried ductile iron pipe fittings, and the steps are: uniformly coating the coating of zinc-aluminum pseudo-alloy as the first layer, evenly Coating of CNSL m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com