Anode Can Sacrificial Mandrels And Fabrication Methods

A manufacturing method and anode technology, which can be used in electrode manufacturing, final product manufacturing, secondary battery manufacturing, etc., and can solve problems such as erosion and obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] What follows is a detailed description of the best known modes of carrying out the invention. This description is not limiting, but merely illustrates the general principles of the invention. For this reason, the present invention can be used in the manufacture of various anode cans.

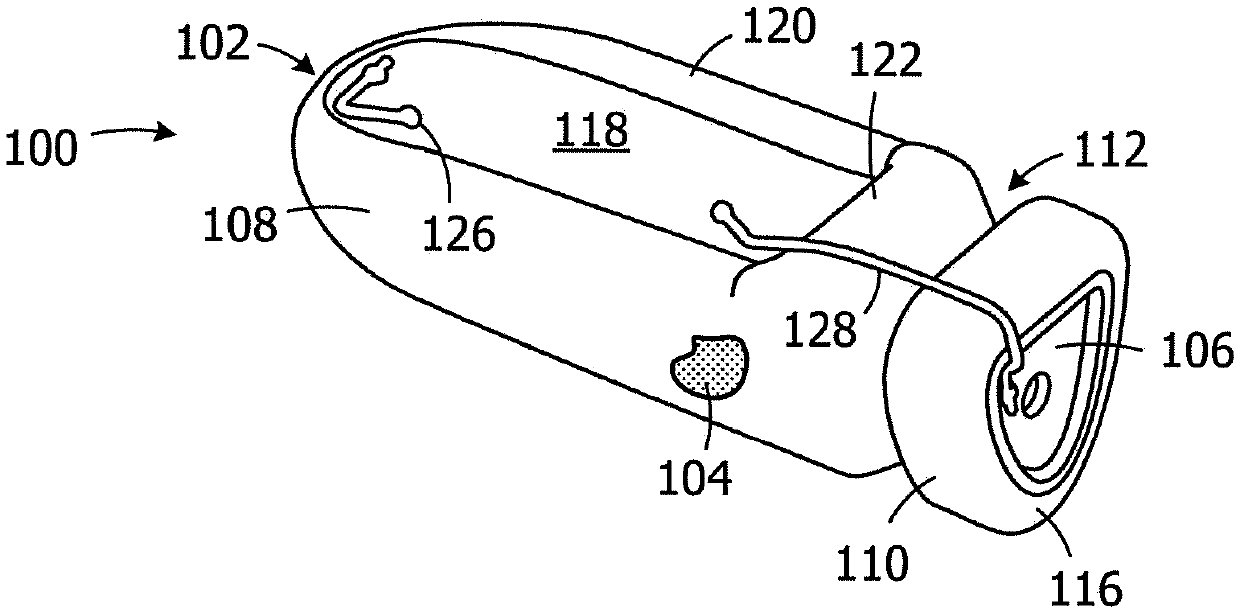

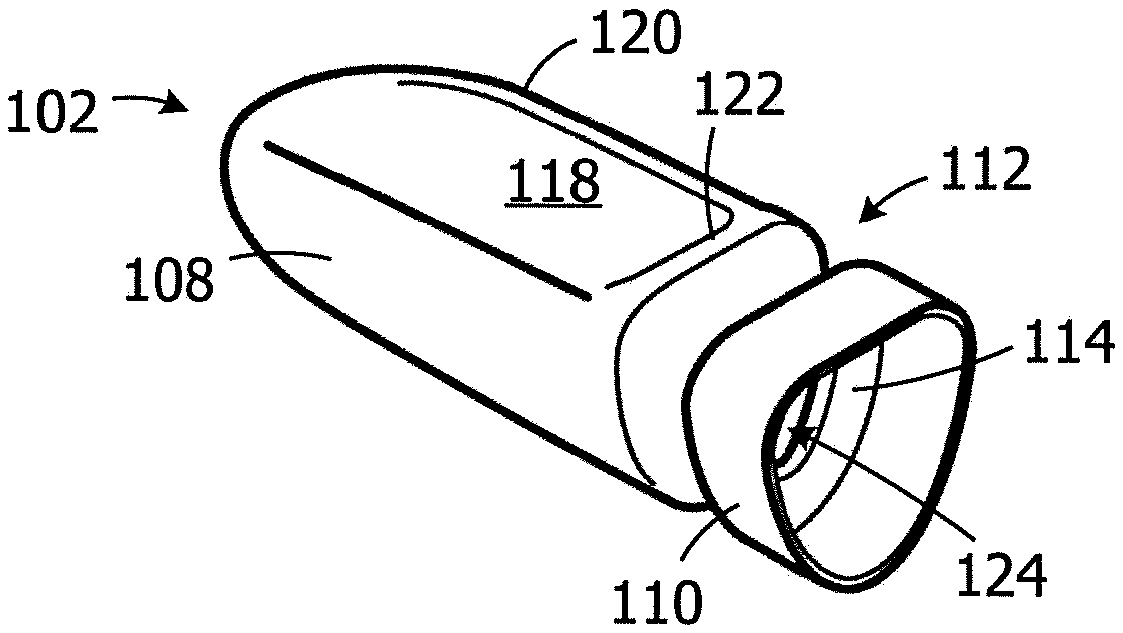

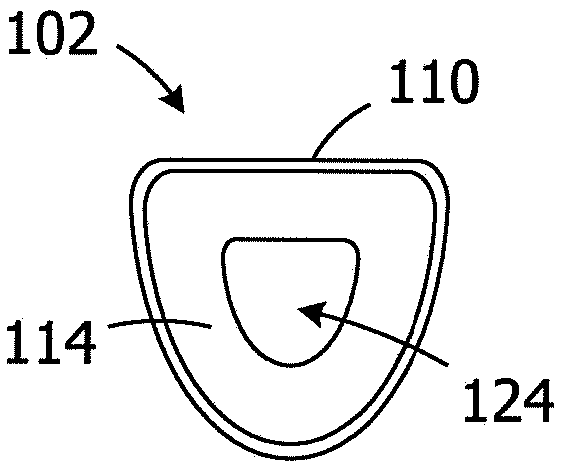

[0022] The exemplary battery illustrated in FIG. 1 includes a hollow anode can 102 (sometimes referred to as a "battery can") that can utilize an exemplary sacrificial mandrel and the following ref. Figure 5A -10 An example of an anode tank fabricated by the fabrication techniques discussed. In addition to the exemplary anode can 102 , the battery 100 includes an anode material 104 and a cathode assembly 106 . Anode can 102 is shown in FIGS. 2-4 in an empty and pre-coiled state, including an anode portion 108 for anode material 104 and a cathode portion 110 for cathode assembly 106 . The exemplary anode can 102 is also provided with an inwardly formed region 112 (or "neck") that define...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com