Method for filtering slurry into filtrate

A technology of filtrate and slurry, which is applied in the chemical industry, can solve the problems of difficult operation, cumbersome methods, inability to effectively control the water content of the filter cake, and the thickness of the filter cake layer, and achieve efficient and rapid filtration, high efficiency, and fast and efficient filtration process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

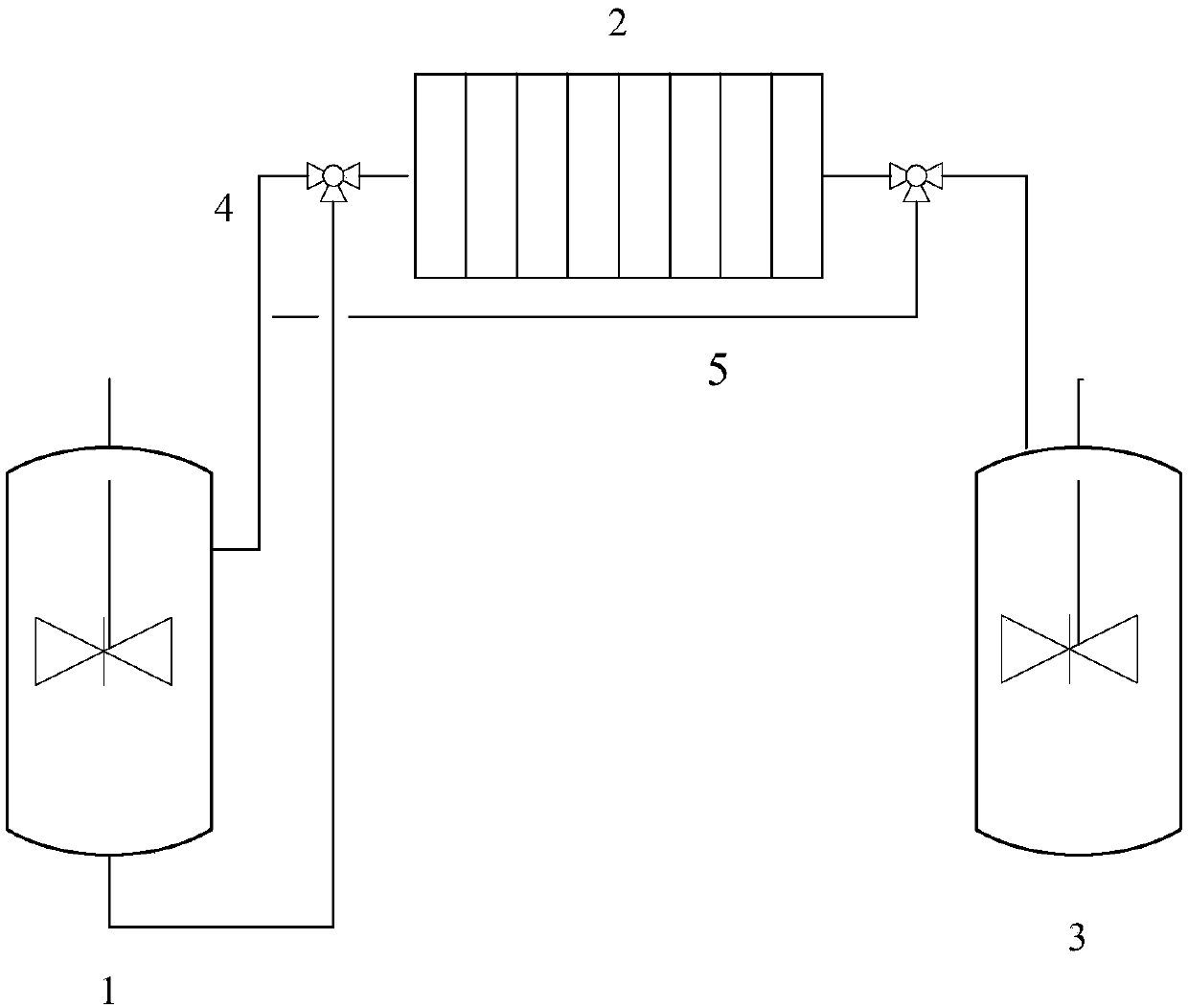

[0050] This embodiment provides a method for filtering slurry into filtrate. The technological process of this embodiment is as figure 1 As shown, the slurry mixing tank 1 communicates with the vertical filter press 2 through the feed pipeline, the discharge pipeline of the vertical filter press 2 communicates with the filtrate buffer tank 3, and the connecting slurry mixing tank 1 is set on the feeding pipeline. The first reflux pipeline 4 is provided with the second reflux pipeline 5 communicating with the mixing tank 1 on the discharge pipeline. The concrete method of this embodiment is:

[0051] (1) Filtration system cleaning and preheating: close the valve entering the vertical filter press 2, circulate the slurry in the feed pipeline and the first return pipeline 4 through the delivery pump, and clean and preheat the pipeline synchronously , the control time is 180s, and the filter cloth of the vertical filter press 2 is preheated with washing water for 200s. The filte...

Embodiment 2

[0057] This embodiment provides a method for filtering slurry into filtrate. The technological process of the present embodiment is with reference to embodiment 1, and concrete method is:

[0058] (1) Filtration system cleaning and preheating: close the valve entering the vertical filter press 2, circulate the slurry in the feed pipeline and the first return pipeline 4 through the delivery pump, and clean and preheat the pipeline synchronously , the control time is 230s, and the filter cloth of the vertical filter press 2 is preheated with washing water for 250s. The filter cloth is made of polypropylene fiber, and the air permeability is 4L / (m 2 ·s), the breaking strength is 6000N / 25mm in warp direction and 1800N / 25mm in weft direction.

[0059] (2) Form filter cake layer under low pressure: close the first return pipeline 4 after step (1) operation is completed, open the second return pipeline 5 and vertical filter press 2 feeding valves, control feed pressure to be 0.2MPa ...

Embodiment 3

[0064] This embodiment provides a method for filtering slurry into filtrate. The technological process of the present embodiment is with reference to embodiment 1, and concrete method is:

[0065] (1) Filtration system cleaning and preheating: close the valve entering the vertical filter press 2, circulate the slurry in the feed pipeline and the first return pipeline 4 through the delivery pump, and clean and preheat the pipeline synchronously , the control time is 300s, and the filter cloth of the vertical filter press 2 is preheated with washing water for 310s. The filter cloth is made of polypropylene fiber, and the air permeability is 4.5L / (m 2 ·s), the breaking strength is 7000N / 25mm in warp direction and 2000N / 25mm in weft direction.

[0066] (2) filter cake layer is formed under low pressure: after the operation of step (1), close the first return pipe 4, open the second return pipe 5 and the feed valve of the vertical filter press 2, and control the feed pressure to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air flow | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com