Automatic clamping feeding device for workpiece convex ring machining

An automatic clamping and tool feeding device technology, which is applied in positioning devices, feeding devices, metal processing, etc., can solve the problems that processing machine tools cannot complete automatic processing, the degree of automation is not high, and the operation of equipment is complicated, so as to save labor costs, Realize the simple effect of automatic tooling and tooling fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

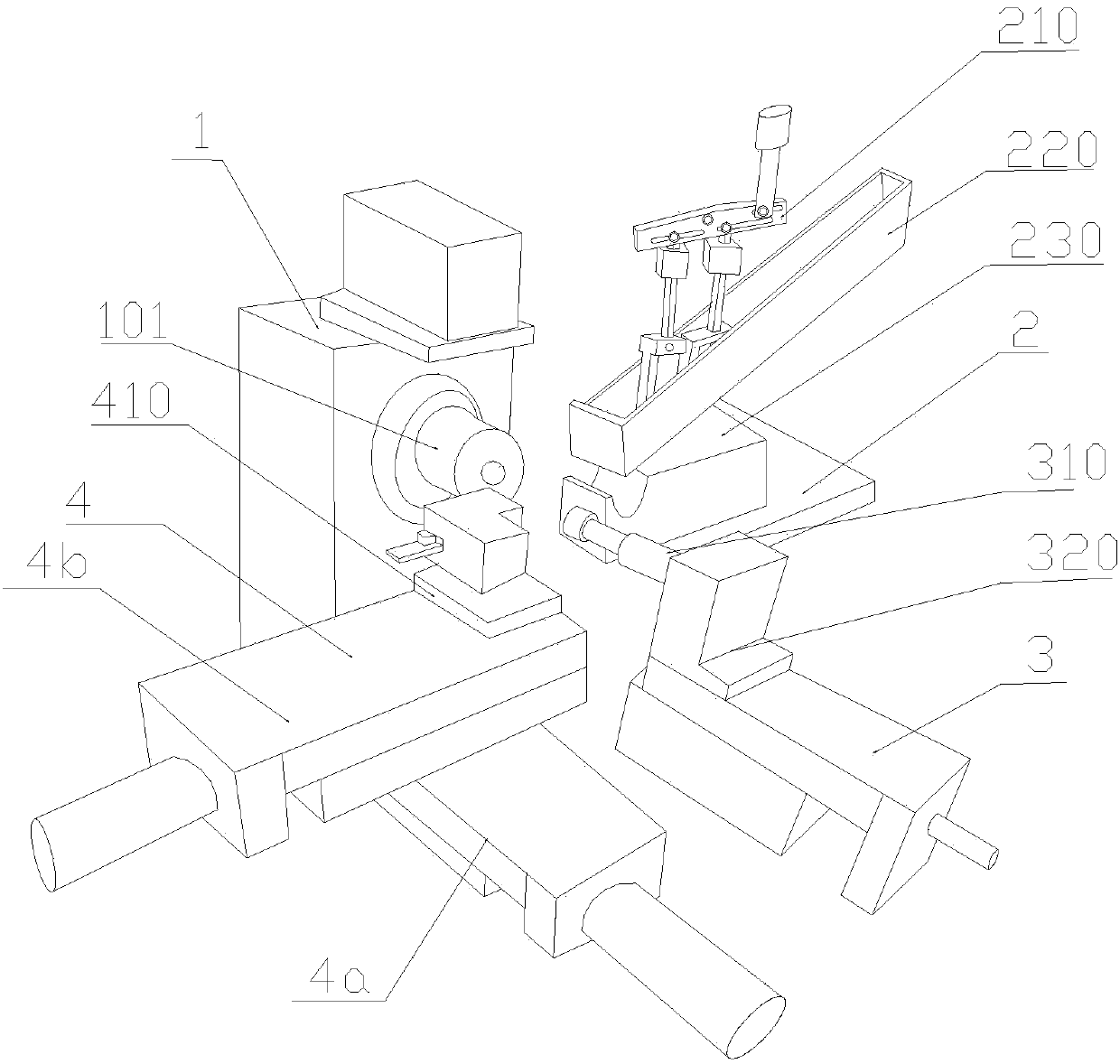

[0039] Such as figure 1 As shown, a workpiece flange processing device includes an automatic feeding mechanism 2, a workpiece clamping mechanism 3, a rotating spindle 101, a gear box 1, and a tool rest mechanism 4, wherein the workpiece clamping mechanism 3 is arranged opposite to the rotating spindle 101, and automatically The feeding mechanism 2 and the knife rest mechanism are respectively arranged on both sides of the axis formed by the workpiece clamping mechanism 3 and the rotating spindle 101 .

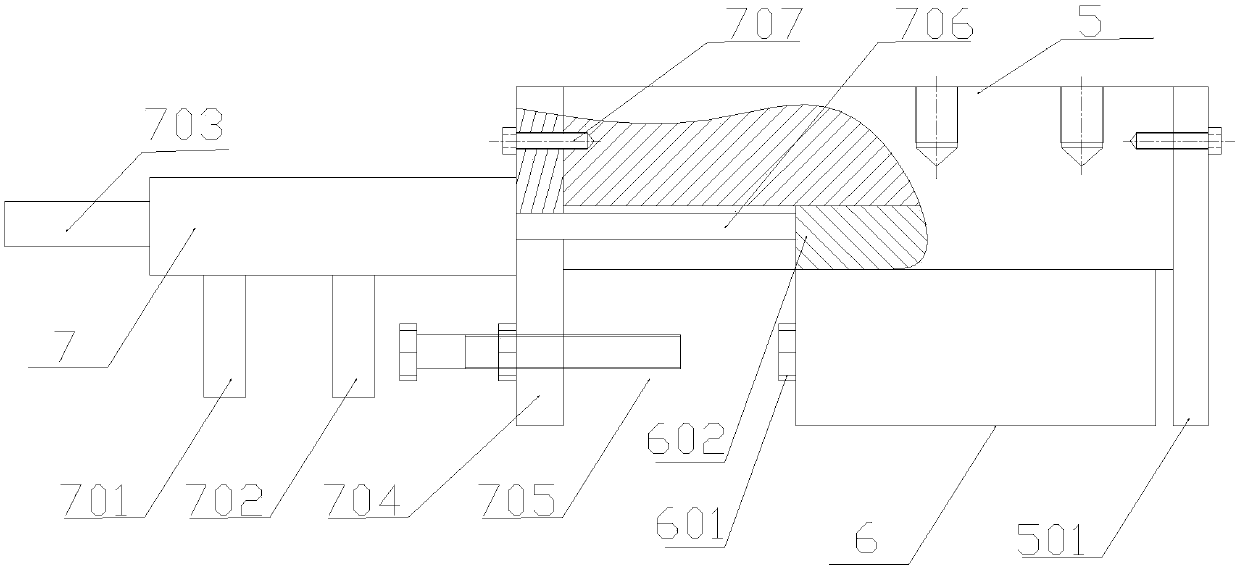

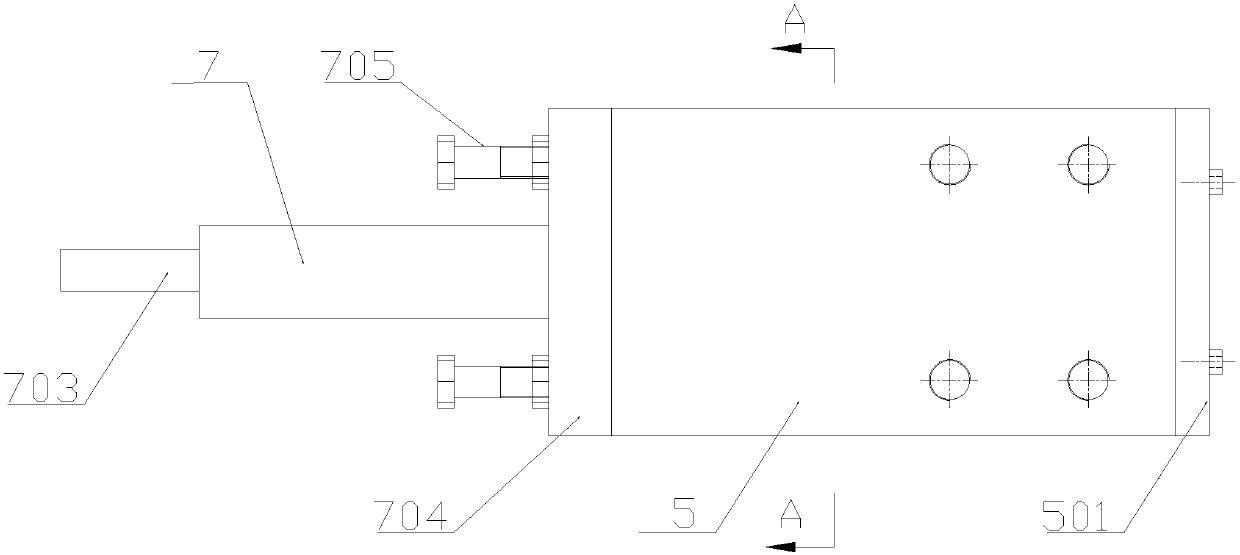

[0040] Such as figure 2 , 3 , Shown in 4, sliding mechanism comprises lower fixed block 6, upper slide block 5, cylinder 7. The lower fixing block 6 is fixed on the base by bolts, and the middle part of the upper end of the lower fixing block 6 is provided with a protruding I-shaped slide rail 602, and the upper slider 5 is provided with an I-shaped slide rail matched with the I-shaped slide rail 602. Slot 502, of course, the lower fixed block 6 can also be provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com