Closed-type direct-reversed circulation impactor

A circular impact, positive and negative technology, which is applied to drilling equipment, earthwork drilling, drilling drive devices in boreholes, etc., can solve problems such as unblocked air return channels, insufficient single impact energy, and large pressure loss along the way , to achieve the effects of avoiding repeated crushing, improving drilling efficiency, and reducing resistance loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

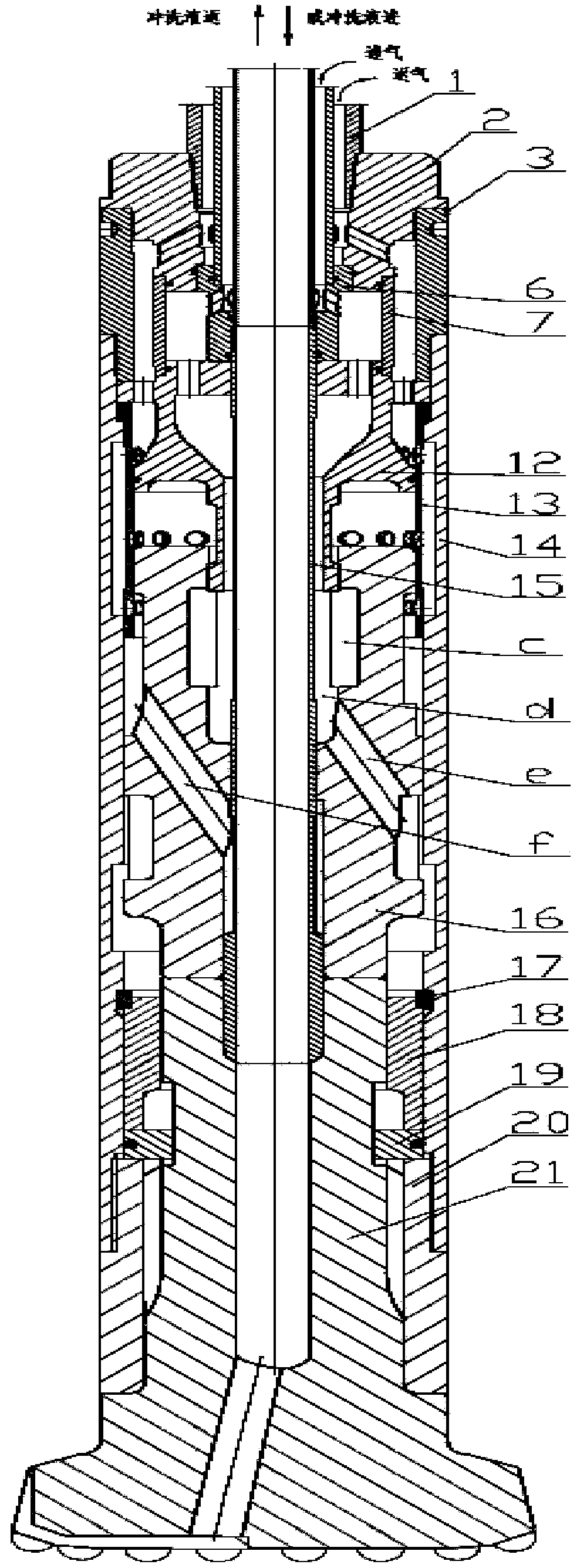

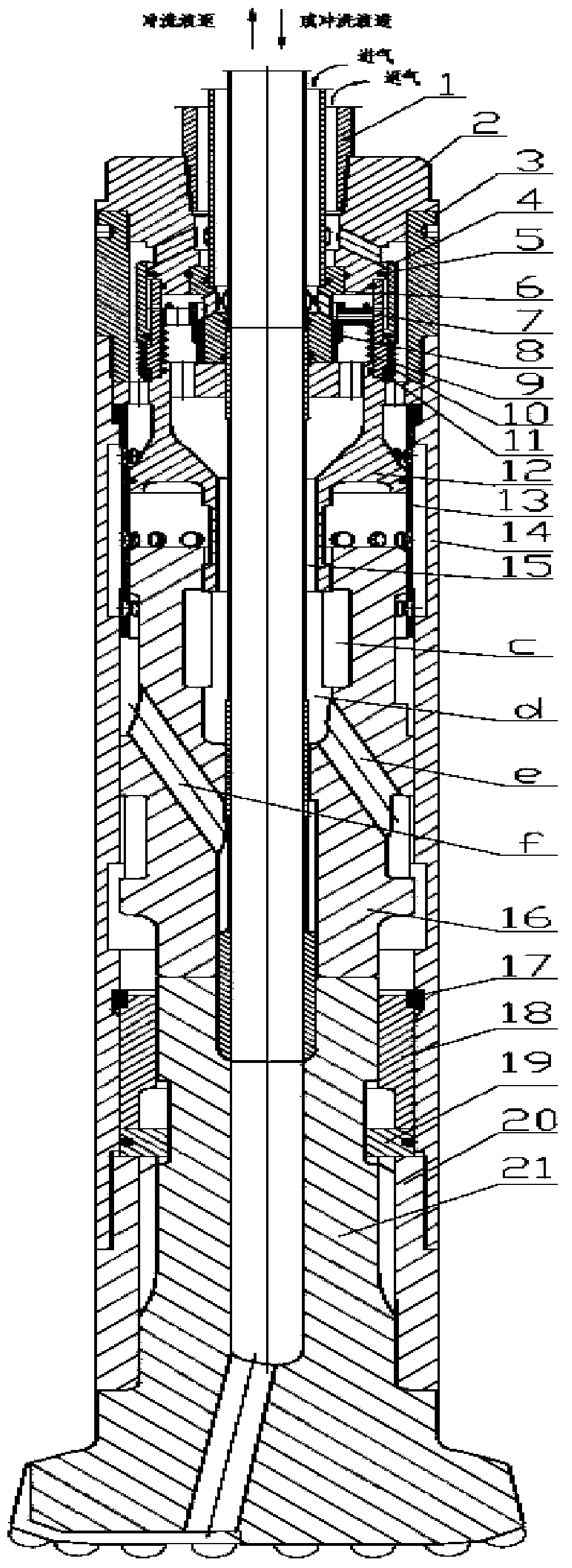

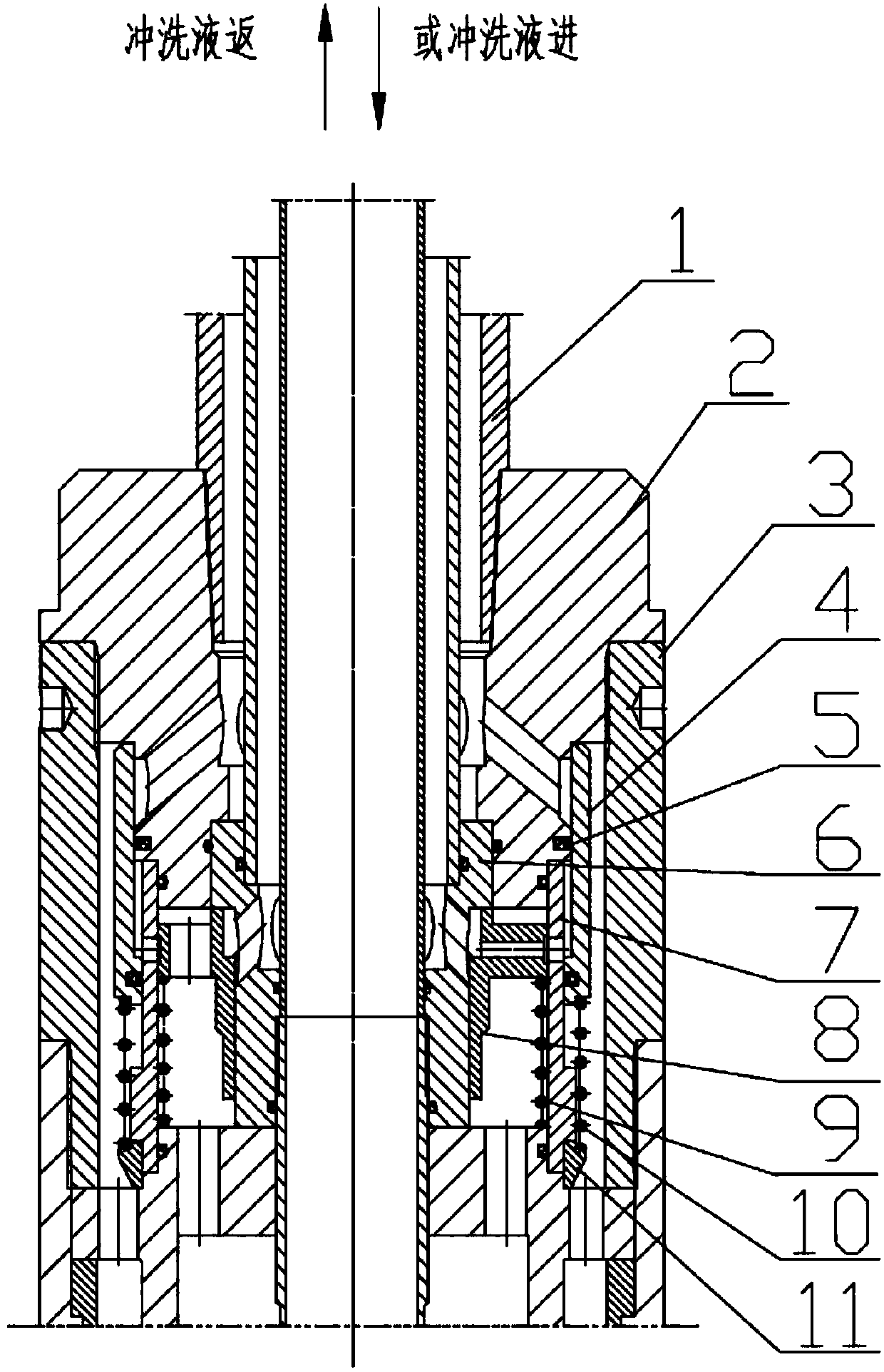

[0029] In order to solve the problems of insufficient single impact energy of the existing closed reverse circulation impactor and the partial blockage of the air return passage, large pressure loss along the process, etc., the present invention first aims at the problem of insufficient impact energy, from the structure of the impactor Starting from the principle, at the level of the principle structure, an air return channel can be formed without adding a layer of outer tube, so that the outer diameter of the piston 16 of the impactor will not cause the outer diameter of the piston 16 to increase due to the addition of an extra outer tube. becomes smaller, and the inner diameter of the piston 16 cannot be avoided because the core pipe 15 is used as the circulation center channel of the mud flushing liquid, so the inner hole of the piston 16 is matched with the outer wall of the core pipe 15 in the structural design, so that this closed type The inner diameter of the piston 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com