Electrolytic magnesium anode sublimate filtering device

A filtering device and sublimate technology, applied in the field of electrolytic magnesium anode sublimate filtering device, can solve the problems of large equipment volume and weight, complicated equipment switching, high equipment cost, etc., and achieve high filtration and purification efficiency, safe and reliable operation, and work adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

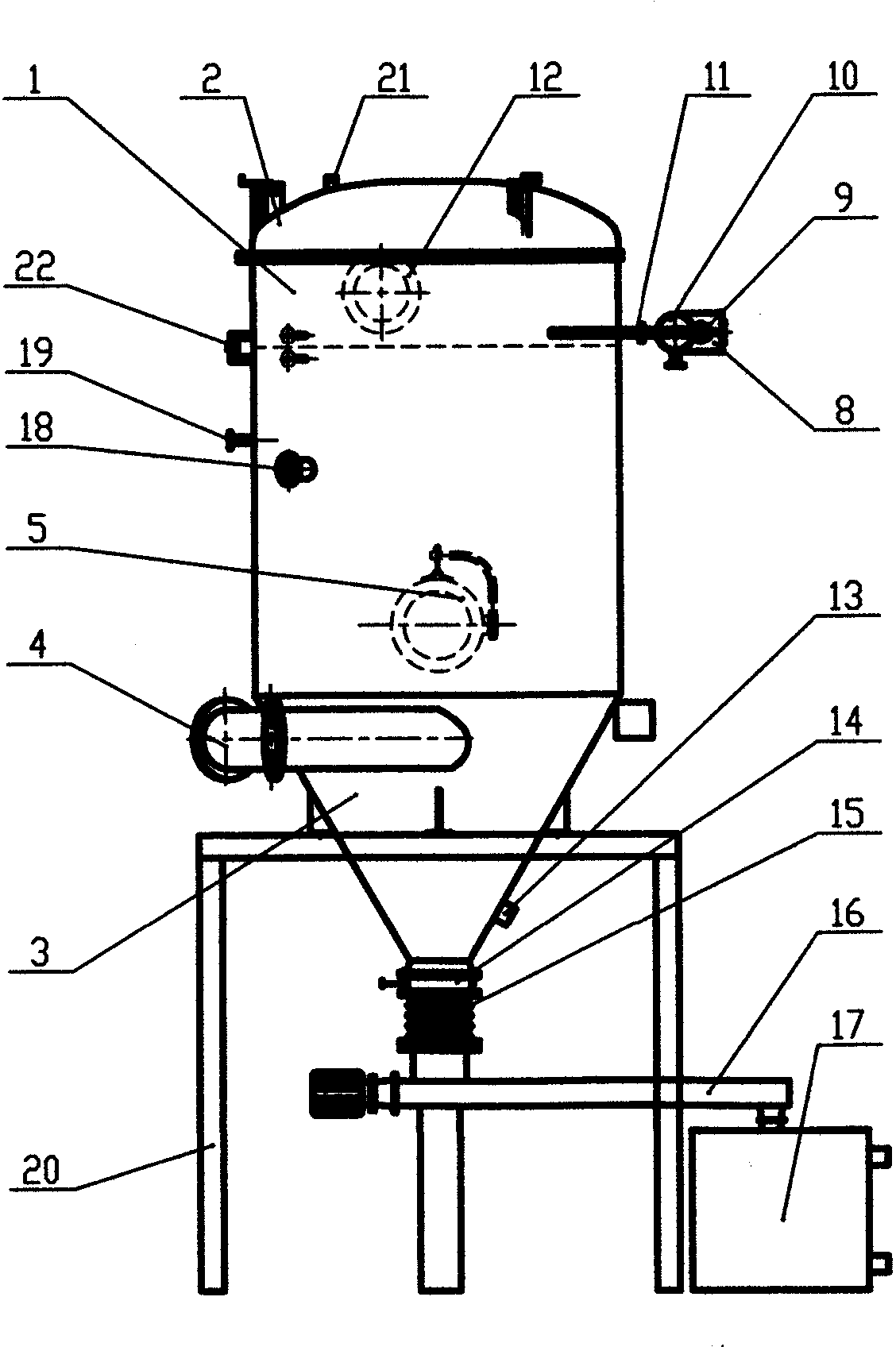

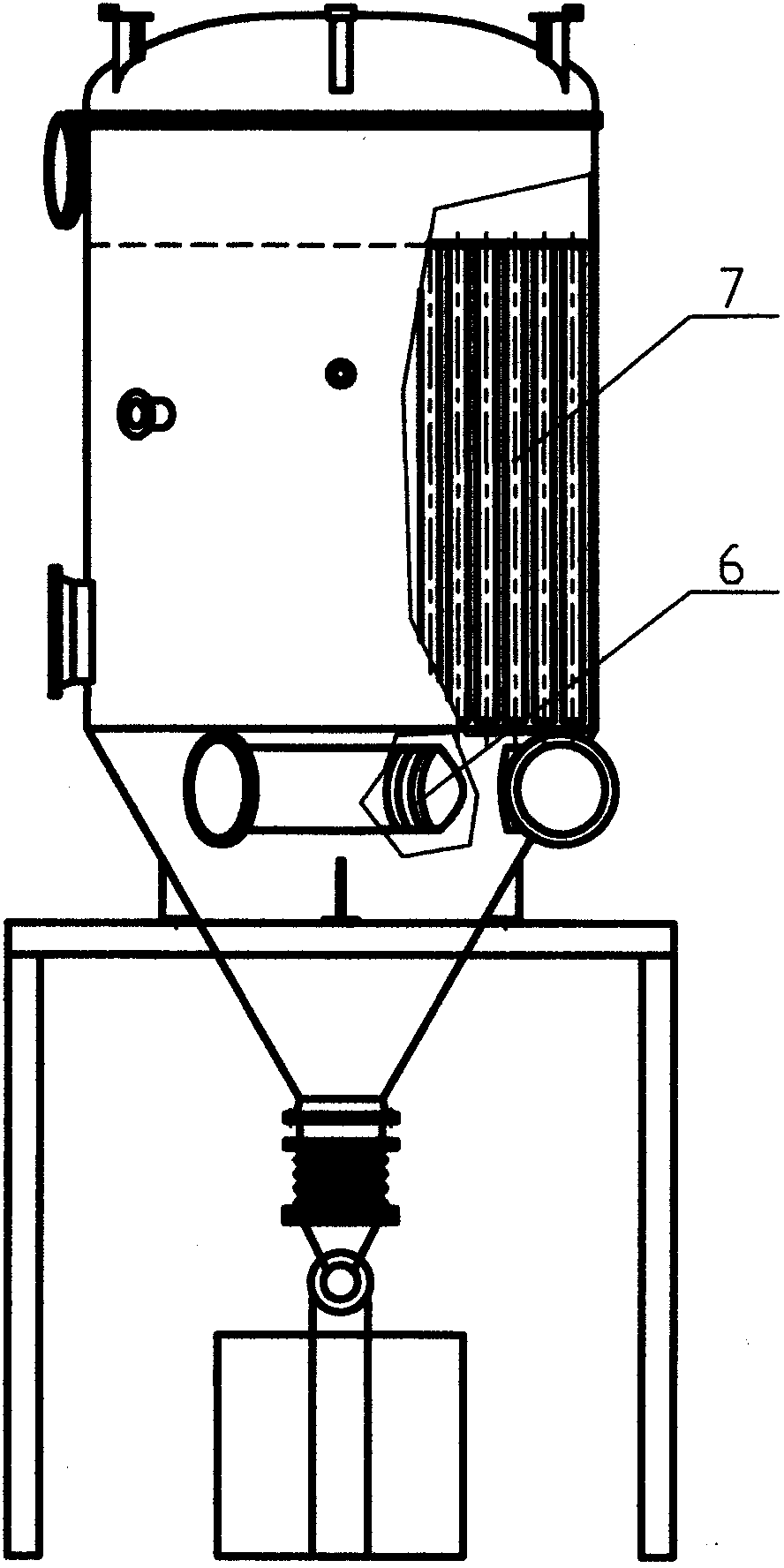

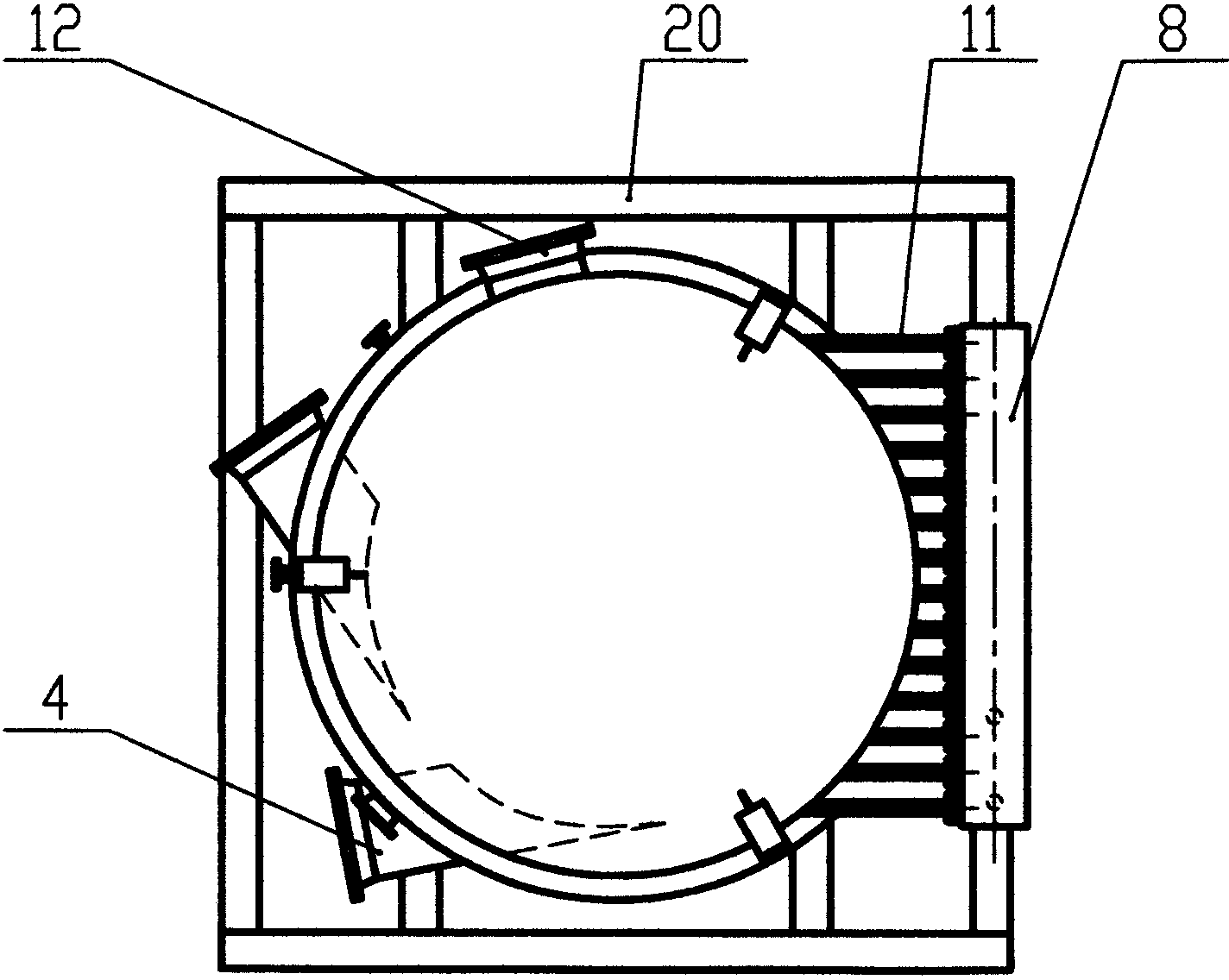

[0013] The filtering device for the electrolytic magnesium anode sublimate of the present invention is realized in this way, which is described in detail below with reference to the drawings.

[0014] see Figure 1 ~ Figure 3 , The electrolytic magnesium anode sublimate filter device is composed of: cylinder 1, elliptical head 2, cone-shaped ash hopper 3, tangential air inlet assembly 4, power-assisted maintenance door 5, air distribution device 6, filter unit 7, pulse Ash cleaning device 8, submerged pulse valve 9, combined sub-cylinder 10, composite injection pipe 11, chlorine outlet assembly 12, ash hopper air hammer 13, ash hopper manual gate valve 14, metal compensator 15, shaftless spiral ash conveying The machine 16, the particle dissolving tank assembly 17, the accident state treatment valve 18, the nitrogen replacement device 19, the bracket 20, the chlorine concentration detector 21 and the differential pressure transmitter 22 are composed of the oval head 2 on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com