Submarine shallow layer non-stratified natural gas hydrate pilot hole pull-back jet break-up exploitation method and exploitation device

A mining method and hydrate technology, which is applied in the fields of fluid mining, mineral mining, earth square drilling, etc., can solve the problems of lack of implementation process methods, difficulty in ensuring the economy of hydrate, and suspension state, so as to reduce the difficulty of transportation technology and The effect of transporting energy consumption, avoiding geological and environmental disasters, and avoiding engineering geological disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

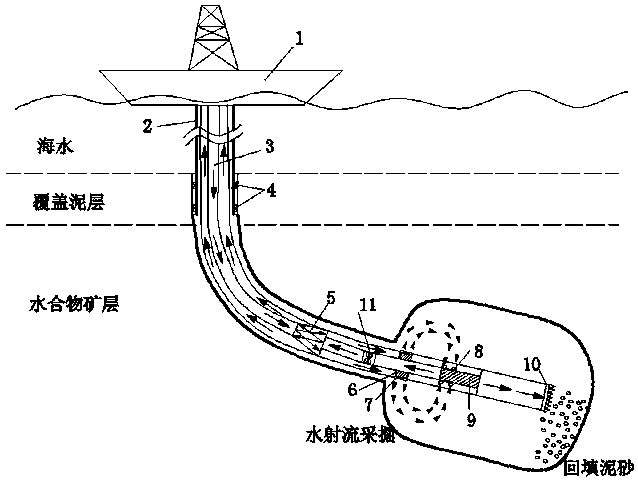

[0018] Exemplary embodiments embodying the features of the present invention will be described in detail in the following description. It should be noted that the present invention can have different changes in different embodiments, and the present embodiment and the accompanying drawings are only used for illustration and are not intended to limit the present invention.

[0019] The pilot-back dragging jet extraction method for subsea shallow non-diagenetic natural gas hydrate according to the embodiment of the present invention includes the following steps:

[0020] Step S1: lower the riser to the top of the seabed hydrate layer to form a vertical channel, and use the intelligent drilling robot 10 to drill horizontally in the hydrate layer to form a certain length of horizontal pilot;

[0021] Step S2: dragging the composite intelligent drilling robot 10 back, and at the same time, the hydrate ore bodies around the pipeline are broken by means of water jet diameter expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com