Wind power generator set and vane deicing device thereof

A technology of blades and blade chords, applied in the field of wind power generation, can solve problems such as increased workload, electrode splitting, and inappropriateness, and achieve the effects of avoiding power waste, preventing misalignment, and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

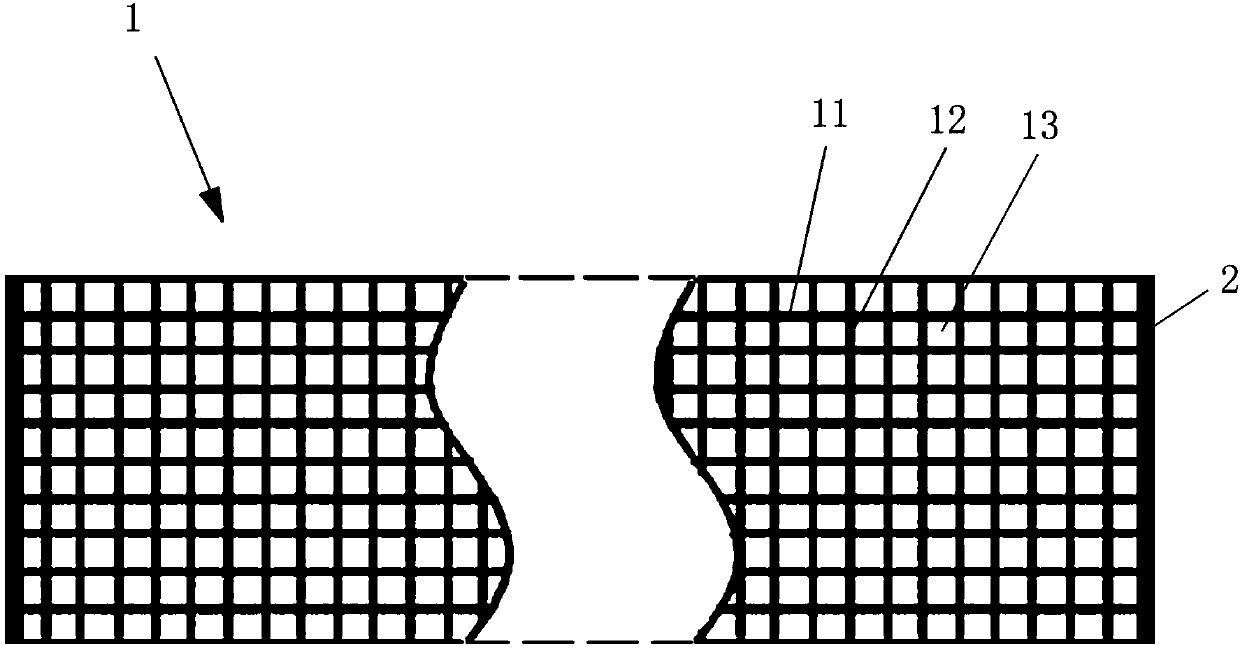

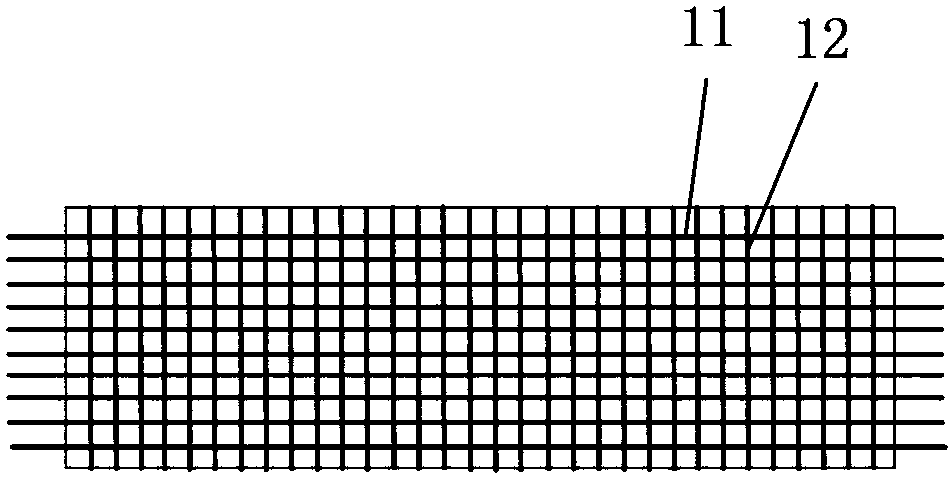

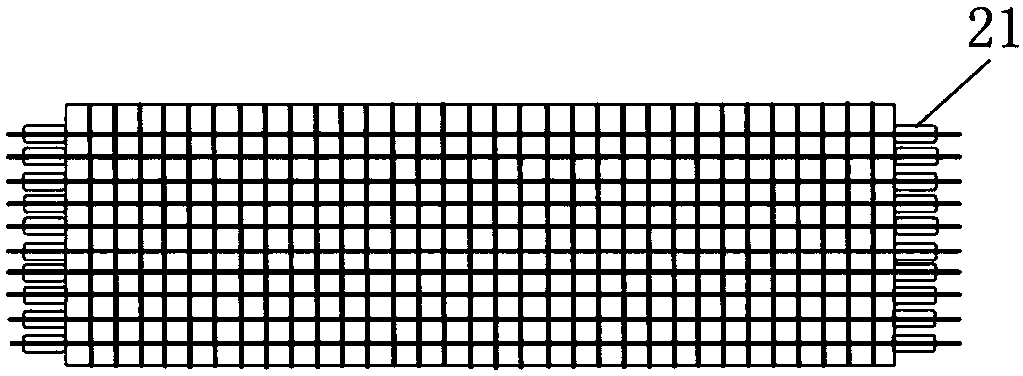

[0031] refer to figure 1 , shows the electric heating element of the blade deicing device according to the embodiment of the present invention. exist figure 1 In , the horizontal direction is called the blade length direction, and the vertical direction is called the blade chord length direction based on the position where the heating element is installed on the blade. Although this is defined here, in actual assembly, the electric heating element can be turned 90 degrees to lay, so that the horizontal direction and the vertical direction can be interchanged, and are not limited to the fixed orientation here.

[0032] According to an embodiment of the present invention, a blade deicing device for deicing blades is provided. Generally, the blade deicing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com