Method of testing burning explosion characteristics of combustible gas at high temperature

A characteristic testing and gas technology, applied in the direction of material explosiveness, can solve the problems of inability to accurately determine combustion and explosion, inability to effectively determine whether the oxidation or decomposition reaction of combustible gas and oxygen has occurred, and achieve good technical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

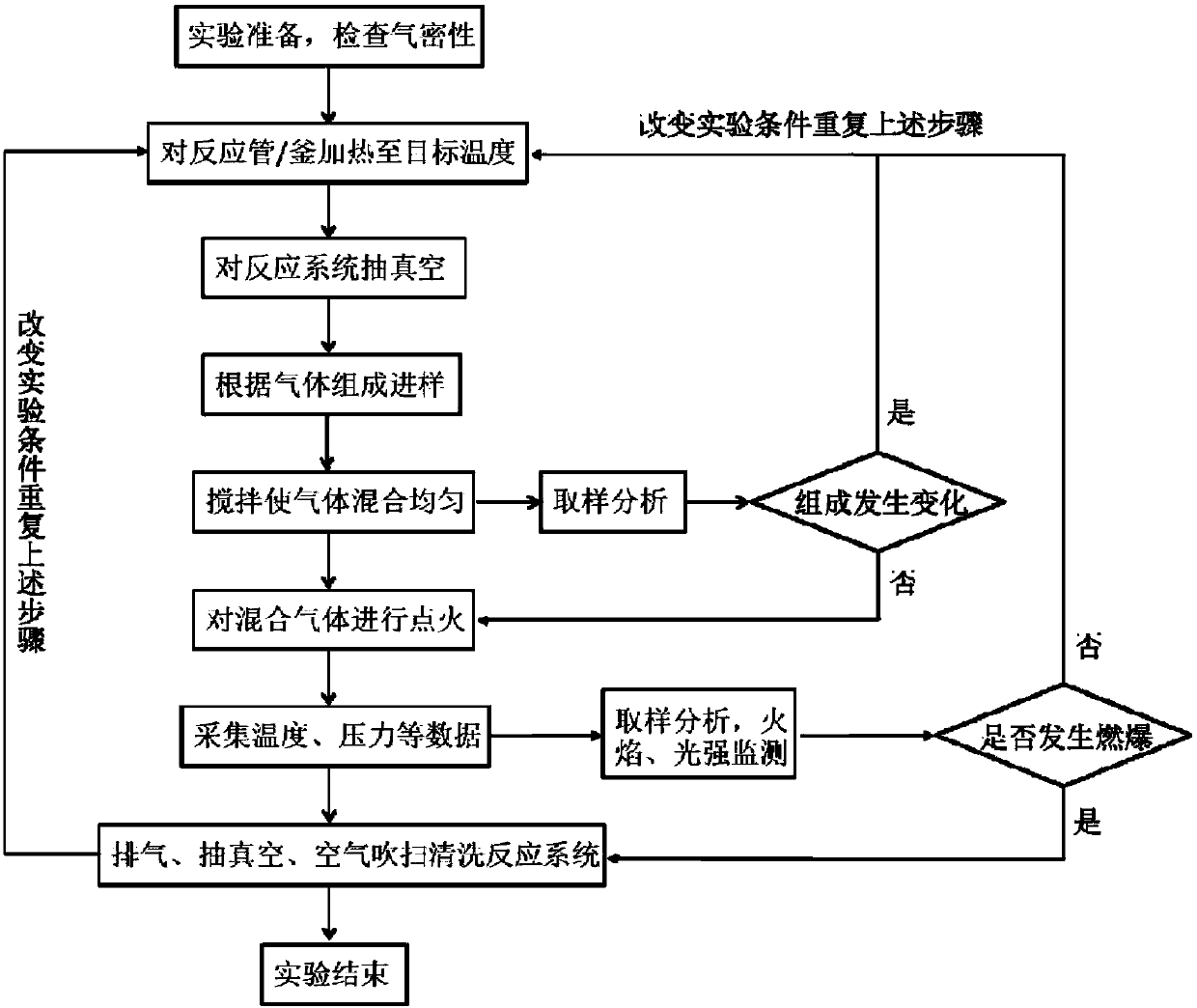

[0018] A test method for the combustion and explosion characteristics of combustible gases under high temperature conditions, such as figure 1 As shown, the explosion limit test device for tubular, kettle or spherical reactors includes the following steps: (1) firstly, according to the temperature and pressure of the test system, the reactor is heated to the target temperature; (2) using Vacuumize the reactor with the vacuum pump until the reading of the connected vacuum gauge is stable; (3) Inject the sample into the reaction system, or use the partial pressure method to feed the gas into the reactor through the gas distribution system according to the composition of the measured gas. Oxygen, then inert gas, and finally combustible gas; (4) Stir the mixed gas in the reactor for 2-5 minutes to make it fully mixed; (5) Perform chromatography-mass spectrometry analysis on the mixed gas to determine the Whether the mixed gas has reacted; (6) ignite the mixed gas, collect and reco...

Embodiment 2

[0026] According to the conditions and steps described in Example 1, the reaction system in this experimental test uses a tubular reactor, uses heating tiles to heat the tube body, uses a gas chromatography-mass spectrometer to analyze the composition, and uses an image and light intensity acquisition card to monitor the flame. Real-time recording, using temperature and pressure sensors to collect temperature and pressure data. Experimental testing methods and steps are as follows:

[0027] First, air purge the entire test system and check the air tightness. After confirming that there is no air leakage, heat the reaction tube to 400°C;

[0028] Vacuum the reaction system until the reading on the vacuum gauge is -99.4KPa and does not change. First, a certain amount of oxygen is introduced into the reaction tube until the reading on the vacuum gauge is -81.5KPa, and then a certain amount of nitrogen is introduced until the reading on the vacuum gauge is -8.6KPa. , and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com