Burr grinding device and method for oil pump rotor of automobile braking system

An automobile brake system and oil pump technology, which is applied to machine tools, grinding/polishing equipment, and grinding machines suitable for grinding the edge of workpieces, can solve the problems of burrs hurting hands, low work efficiency, and high labor costs, and achieve reduction Human cost, improve work efficiency, design scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

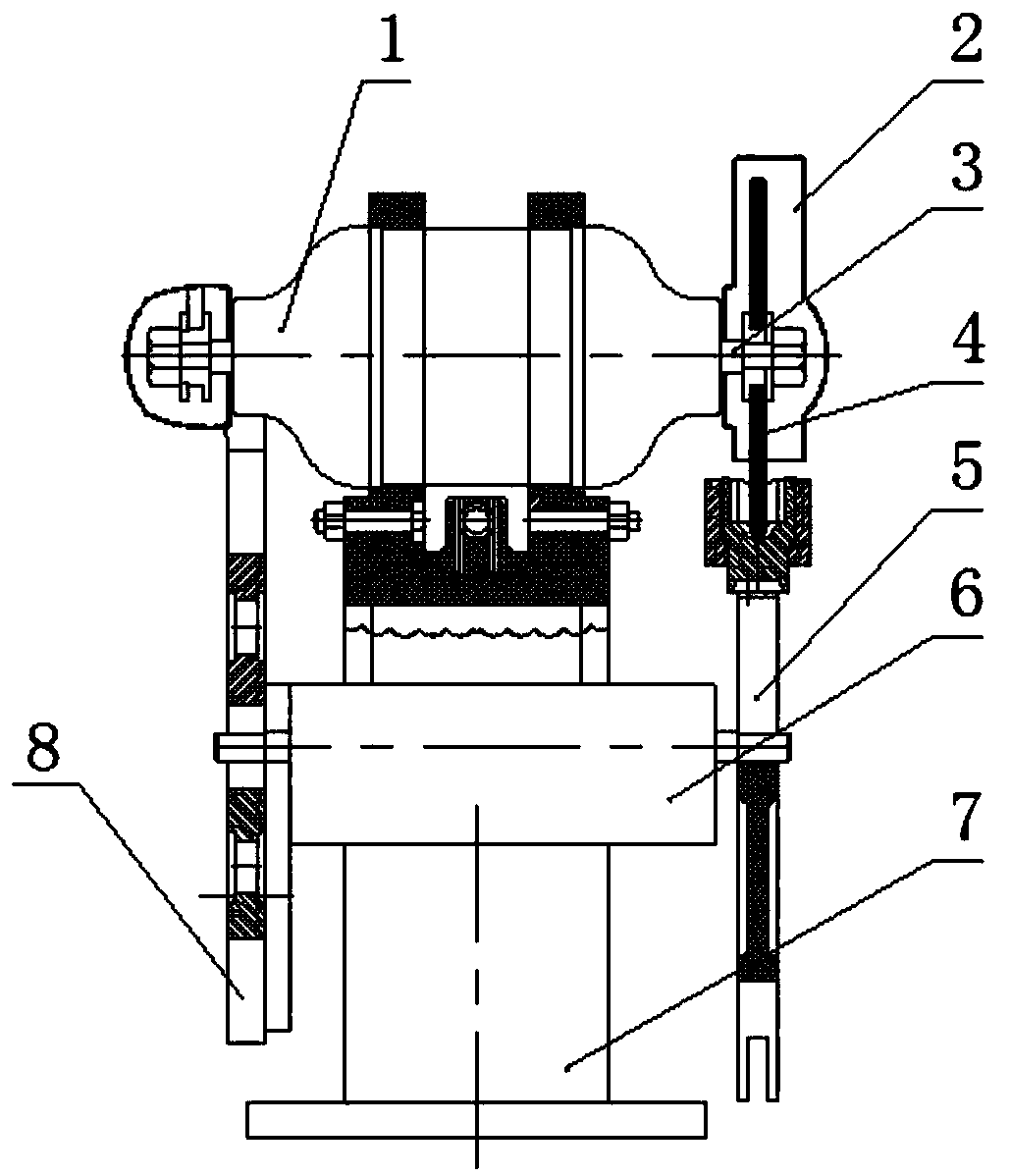

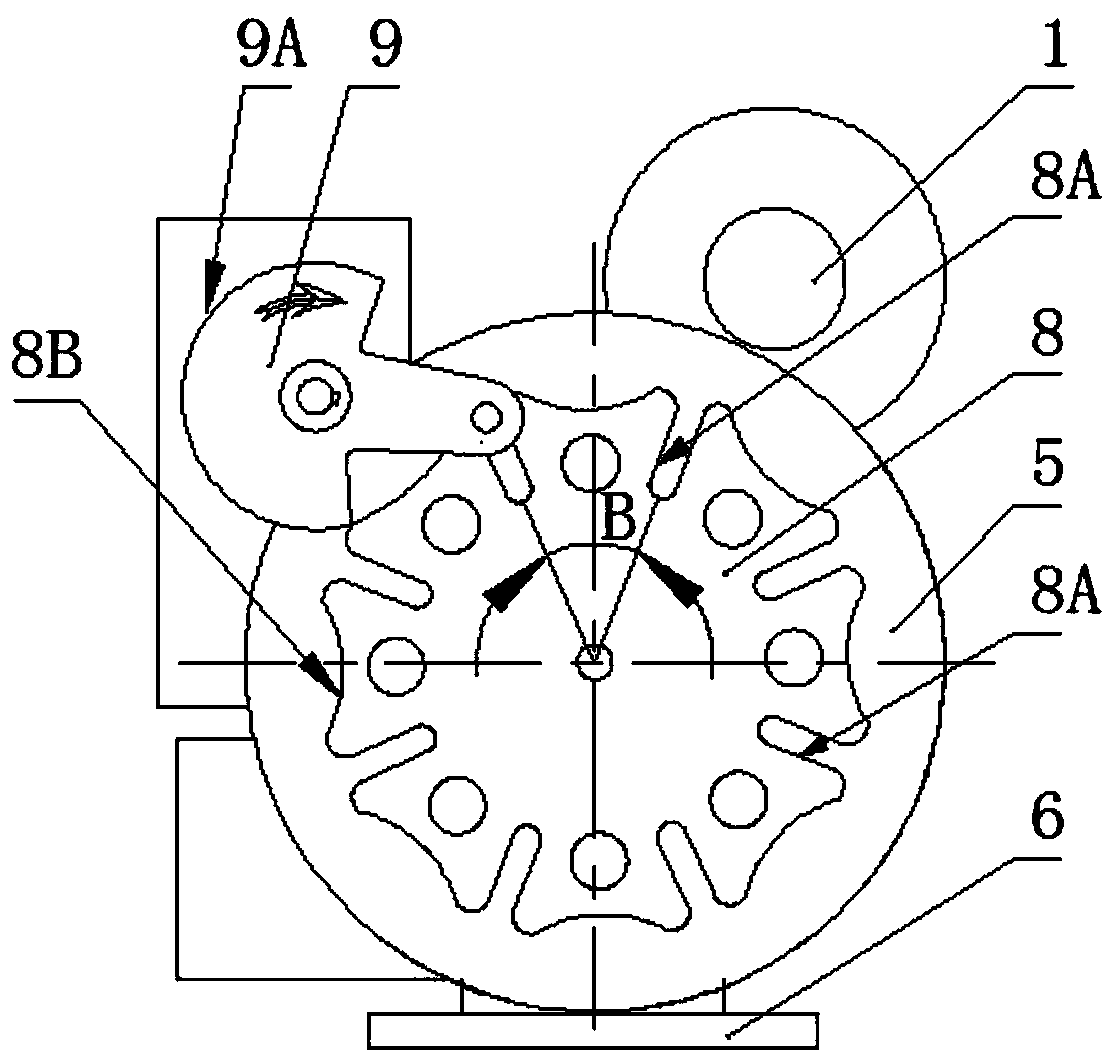

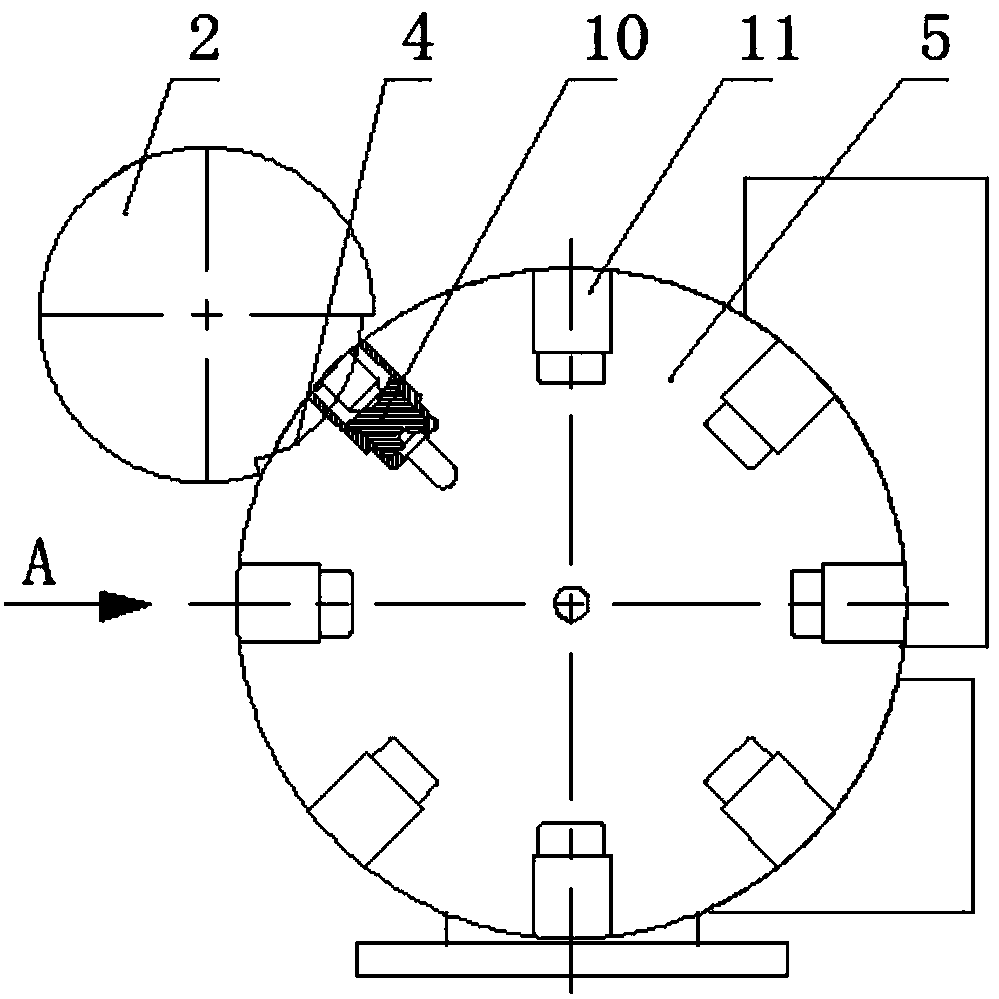

[0027] A grinding and burring device for the oil pump rotor of the automobile brake system, such as figure 1 , figure 2 , image 3 As shown, it includes a frame 7, a grooved wheel 8, a part wheel 5 and a grinding wheel 4. The frame is installed with a rotating shaft 6 horizontally, the right end of the rotating shaft is coaxially installed with a part wheel, and the left end of the rotating shaft is coaxially installed with a grooved wheel. The part wheel disc rotates synchronously with the groove wheel disc, and a grinding wheel is installed on the frame above the corresponding part wheel disc, and the grinding wheel rotates at a high speed so that the burrs of the parts 10 installed on the part gear are ground clean.

[0028] The driving method of the part wheel is: a pin wheel 9 is installed on the top of the frame, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com