Elastic assembly of side bearing and manufacturing method of elastic assembly

A technology of elastic components and metal plates, which is applied in the direction of the device for lateral relative movement between the chassis and the bogie, can solve the problems of complex processing technology of elastic components, unstable friction torque, unfavorable environmental protection, etc., and achieve easy maintenance in the later stage , Reduced side bearing specifications, easy maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

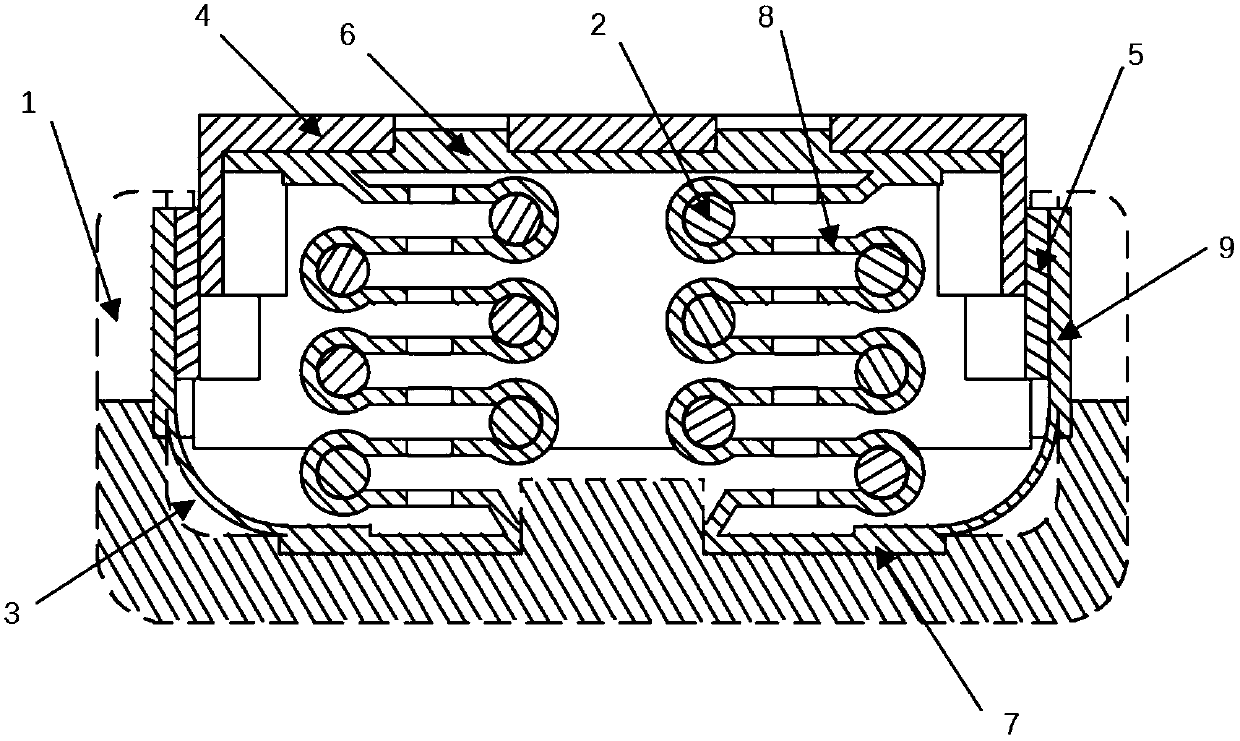

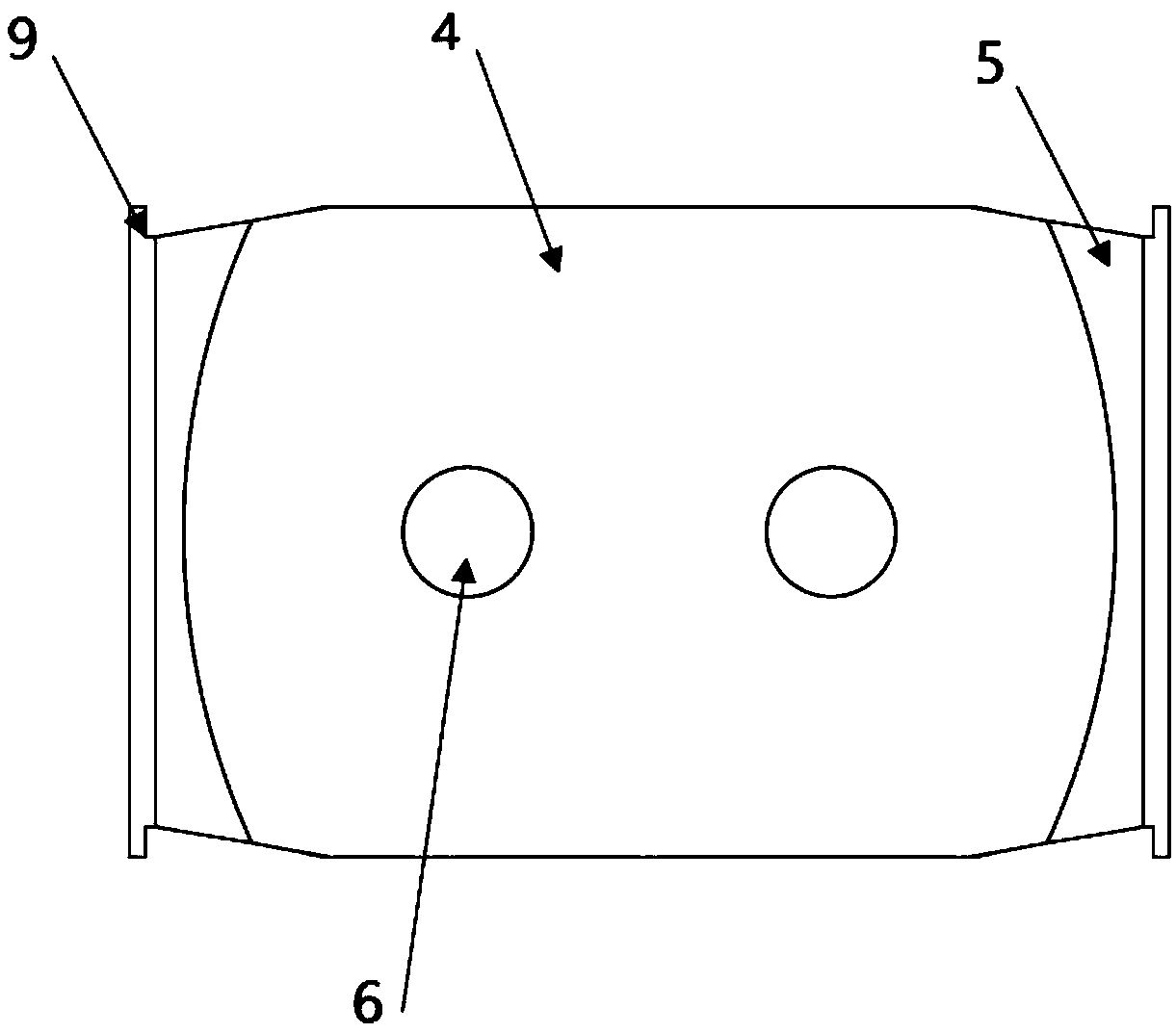

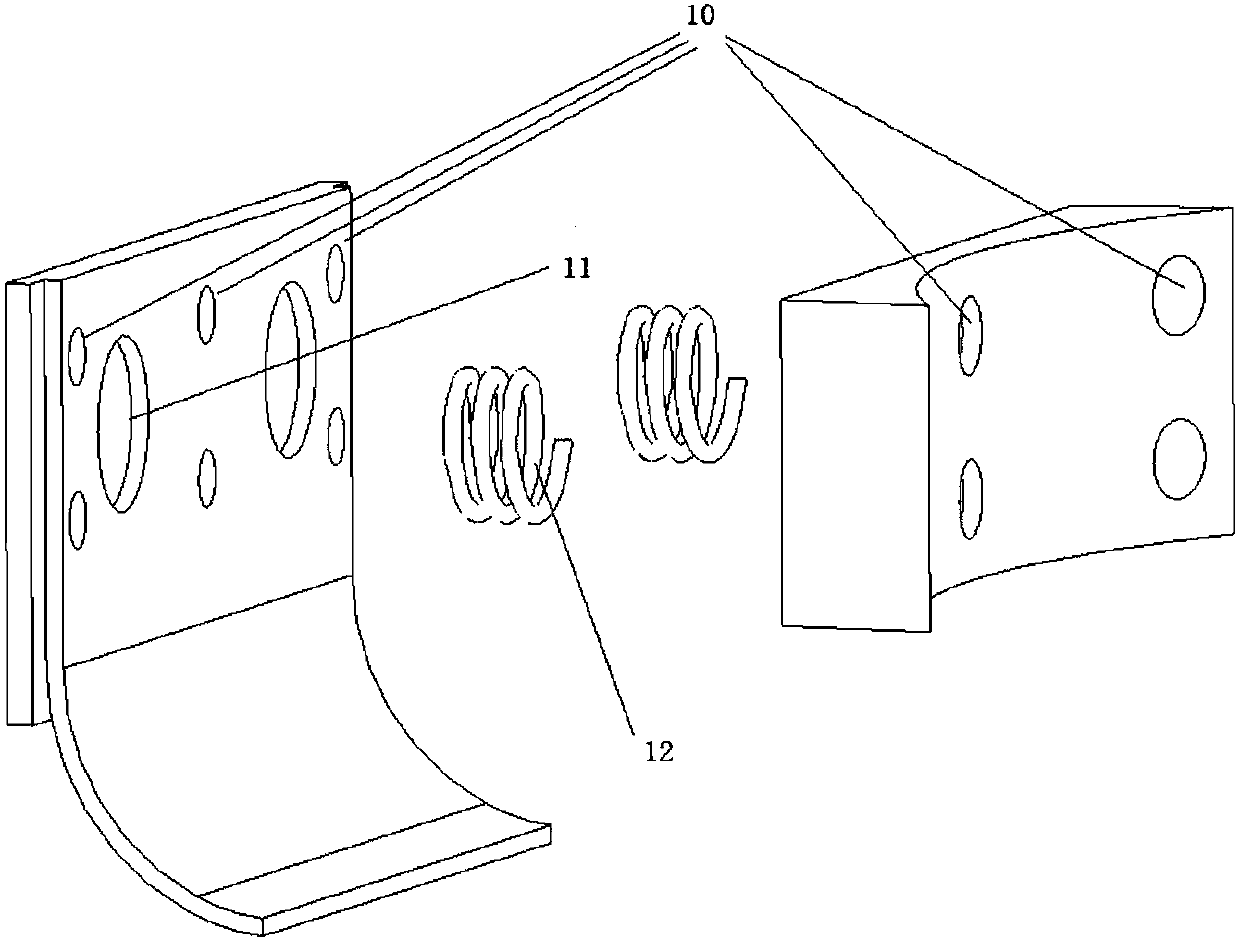

[0023] like Figure 1-2 As shown, the elastic side bearing includes a side bearing box 1, which is equipped with a side bearing packaging frame 3 and a side bearing elastic assembly. The side bearing packaging frame includes a base 7, a main body upper plate 6 and a main body side ear 9. The side bearing elastic The components are assembled between the base 7 and the main body upper plate 6, and the side bearing elastic components include two multi-layer S-shaped metal plates 8, the materials and layers of the two S-shaped metal plates (8) are the same, and the two S-shaped metal plates (8) The metal plates are arranged anti-symmetrically. The number of multi-layer S-shaped metal plates can be set according to actual needs. There is a transition arc at the corner of the metal plate, and the arc surrounds a hollow slot, which is detachably assembled in the hollow slot. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com