Transverse large volume sample injection system and method for gas chromatography

A large-volume sampling and gas chromatography technology, applied in the field of detection instruments, can solve the problems of unfavorable popularization, difficult operation, complicated design, etc., and achieve the effects of simple structure, improved sensitivity, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

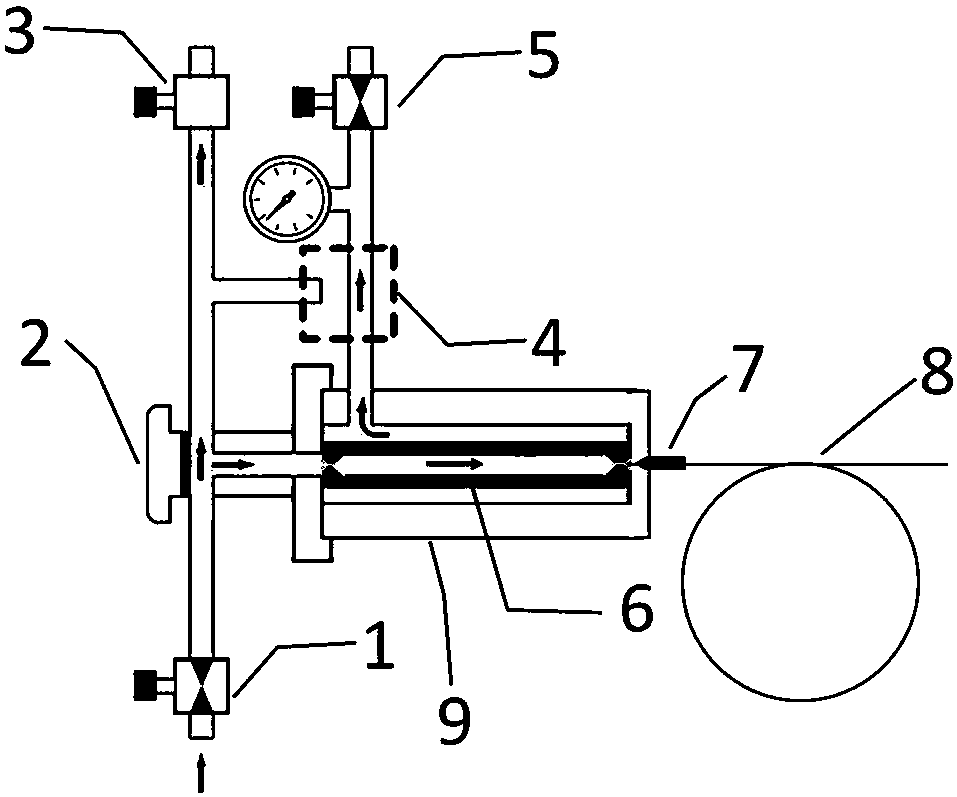

[0047] A kind of horizontal large-volume sampling system and method for gas chromatography, such as figure 1 As shown, including total flow control valve 1, septum nut and septum 2, septum purge control valve 3, split valve 4, split vent control valve 5, liner 6, column nut and seal 7, column 8. The temperature control module 9 is characterized in that the liner 6 is a double-cone split-less liner, placed horizontally, that is, placed parallel to the ground, the septum nut and the septum 2, the column nut and the gasket 3 , chromatographic column 8, and position 9 of the temperature control module are also changed accordingly. The horizontal direction from front to back is the septum nut and septum 2, liner 6, column nut and gasket 7, and chromatographic column 8. The module 9 wraps the liner 6 laterally; a liner support ring 16 may also be provided to keep the liner in a horizontal state. The specific operation mode is:

[0048] 1. Preparatory stage before sample injection:...

Embodiment 2

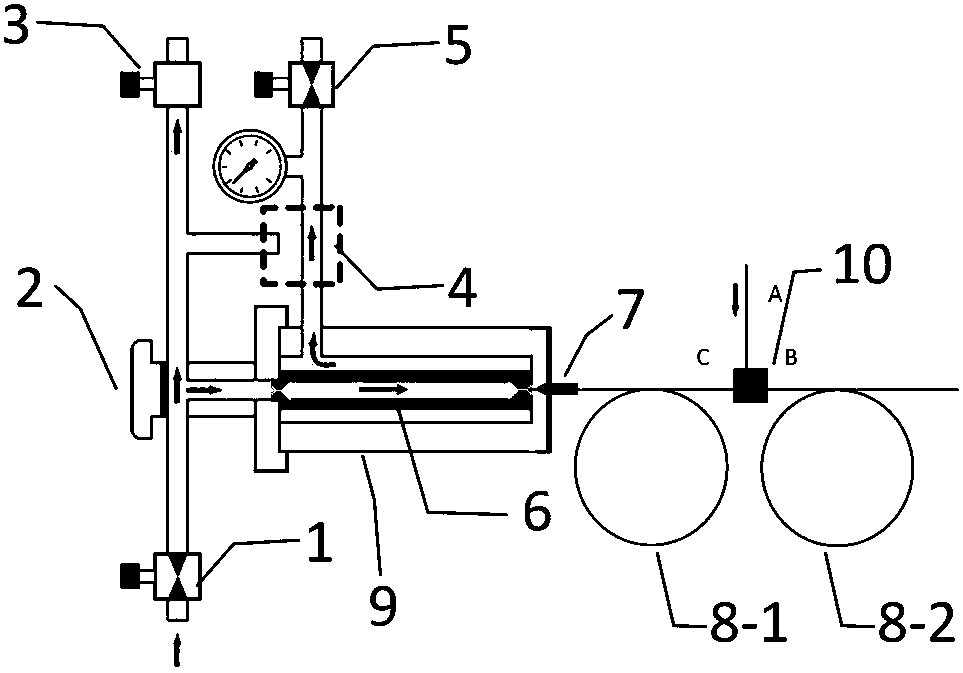

[0055] A kind of lateral large-volume sampling system and method for gas chromatography as shown in Embodiment 1, further, as figure 2 As shown, a three-way valve 10 is also included to divide the chromatographic column 8 into a pre-column 8-1 and an analysis column 8-2 to form a backflushing system. The A port of the three-way valve is connected to the gas input pipeline, and the B port is connected to the analytical column , port C is connected to the pre-column, when the target compound passes through the three-way valve 10, the carrier gas is input to port A of the three-way valve, the carrier gas is output from ports B and C, the gas in the analysis column flows to the detector, and the pre-column gas flows to the inlet When the input of carrier gas through port A is stopped, the carrier gas enters the analysis column 8-2 through the pre-column 8-1 and the three-way valve 10 from the sampling system. The specific operation mode is:

[0056] 1. Preparatory stage before s...

Embodiment 3

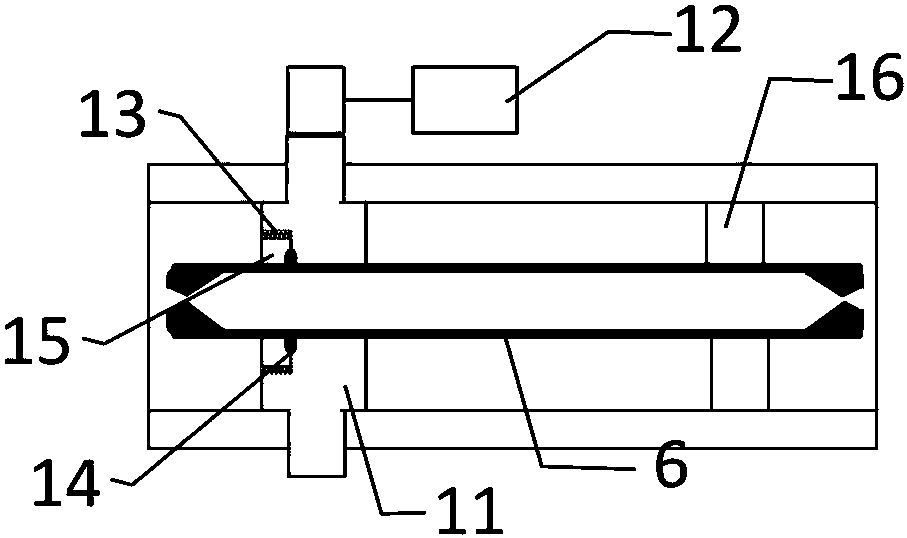

[0063] A kind of gas chromatography large-volume sampling system and method as shown in embodiment one, further, as image 3 As shown, it also includes a bearing 11, a motor 12, an O-ring 14, a fixing nut 15, and a liner support ring 16, which is characterized in that the bearing is provided with a groove 13 with an inner wire, and a The hole of the liner, the liner 6 with the O-ring 14 passing through the bearing 11, the fixed nut 15 with an outer wire, can be screwed into the groove 13, and passed through to press The liner 6 is fixed on the bearing 11 by tightening the O-ring 14, and the other end of the liner 6 is placed in the support ring 16 to maintain a horizontal state, and the bearing rotates under the drive of the motor , the bearing drives the O-ring to rotate, and the O-ring drives the liner to rotate, which accelerates the solvent evaporation and achieves the effect of rotary evaporation. The bearing 11 is in contact with the temperature adjustment module 9 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com